Chinlon or chinlon/cotton blended printed fabric and preparation method thereof

A cotton blending and nylon technology, which is used in textiles and papermaking, textile materials contacting export textile material processing, dyeing methods, etc., can solve the problems of reactive dye printing, the color is not stable enough, the width is inconsistent, and the fabric and the guide roller are colored. , to achieve the effect of improving printing quality, stable production process and flexible product positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

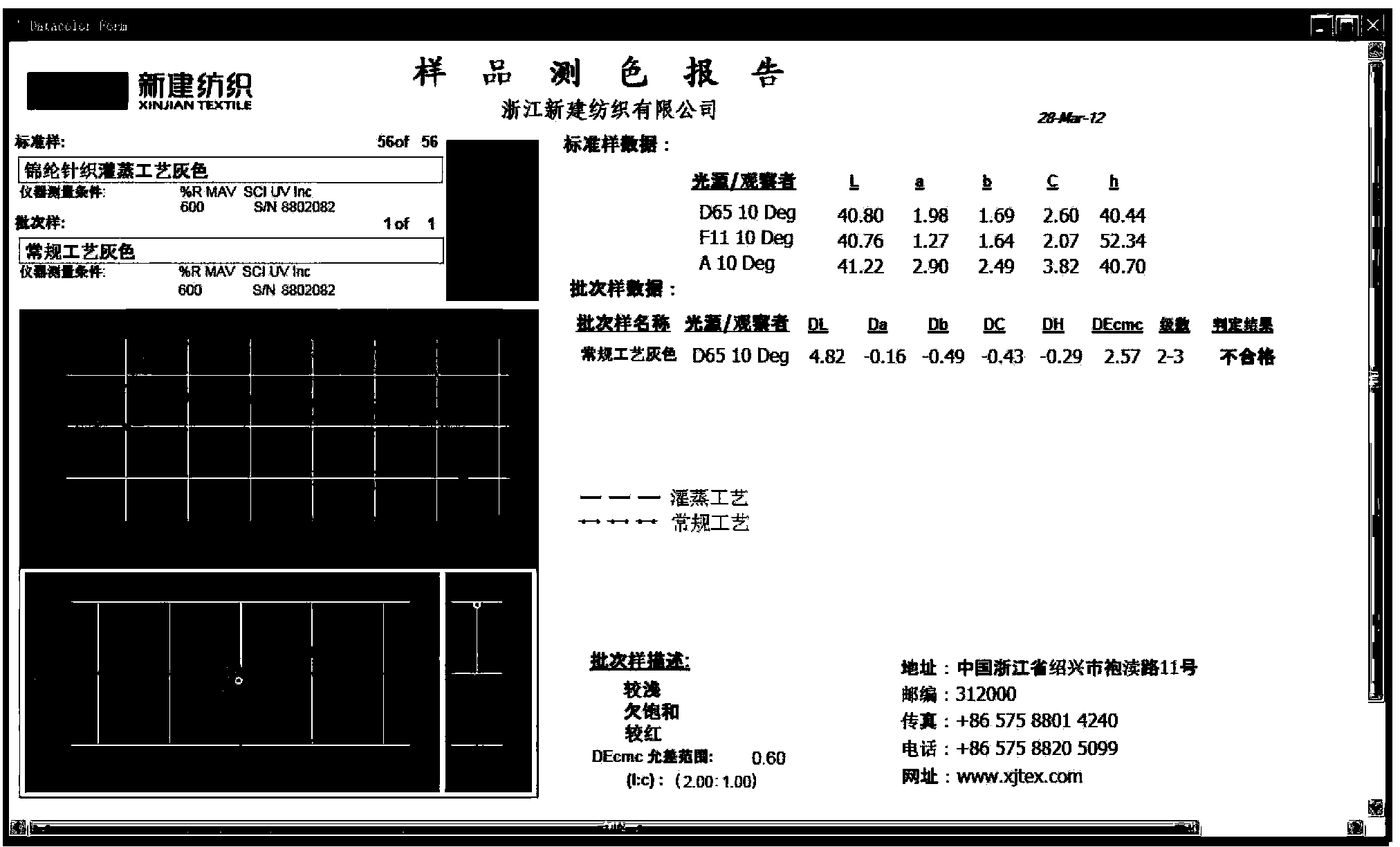

[0031] Embodiment 1, prepare nylon printed fabric

[0032] The dry grammage of the knitted gray fabric used is 140g / m 2 , 111dtex / 96f pure nylon low elastic single-sided mesh fabric.

[0033] (1) Arrange the nylon knitted blank in the overflow dyeing machine for boiling and bleaching; the composition of the bleaching agent used is: sodium hydroxide 2g / l, hydrogen peroxide 4g / l, hydrogen peroxide stabilizer DS (Shandong Julong Chemical) 2g / l and Deyouling TF101D1g / l (Zhejiang Transfar Co., Ltd.), the temperature is 95°C, and the time is 20min.

[0034] (2) Print the boiled and bleached fabric in a circular screen printing machine; the composition of the printing paste used is: Corning Chemical Co., Ltd. 138 paste 45-60%, urea 2%, ammonium sulfate 2.5%; black color paste Dye composition: 2S-LD black 30.8g / l, NHF-S yellow 2.45g / l, NHF-S red 1.45g / l; coffee color paste dye composition: NHF-S blue 7.31g / l, NHF-S yellow 24.2g / l, NHF-S red 2.93g / l; dark green paste dye compositi...

Embodiment 2

[0059] Embodiment 2, prepare nylon printed fabric

[0060] The dry weight of gray cloth used is 170g / m 2 , 30 British pure nylon staple fabric.

[0061] The specific steps are as follows: the fabric is boiled and bleached in the oxygen bleaching machine; printed on the rotary screen printing machine; steamed in the KD-95 pot steamer; soaped in the open-width soaping machine; set and finished on the setting machine.

[0062] (1) Put the pure nylon staple fiber fabric in an oxygen bleaching machine for bleaching; the composition of the bleaching agent used is: sodium hydroxide 8g / l, hydrogen peroxide 6g / l, hydrogen peroxide stabilizer DS (Shandong Julong Chemical) 8g / l and refining agent ZX-95 (Shijiazhuang Huancheng Chemical Factory) 15g / l; the temperature is 100°C, and the time is 30min;

[0063] (2) Print the boiled and bleached fabric in a rotary screen printing machine. The composition of the printing paste used is: the composition of the printing paste used is: Corning ...

Embodiment 3

[0088] Embodiment 3, prepare nylon / cotton blended printed fabric

[0089] The dry weight of gray cloth used is 210g / m 2 , nylon / cotton 50 / 50 woven fabric.

[0090] (1) The nylon / cotton blended fabric is bleached in an oxygen bleaching machine; the composition of the bleaching agent used is: sodium hydroxide 18g / l, hydrogen peroxide 6g / l, hydrogen peroxide stabilizer DS (Shandong Julong Chemical) 8g / l. Refining agent ZX-93 (Shijiazhuang Huancheng Chemical Factory) 12g / l and penetrating agent JFC (Shandong Julong Chemical Industry) 5g / l, the temperature is 100°C, and the time is 40min;

[0091] (2) Mercerize the boiled and bleached fabric: use sodium hydroxide concentration (220g / l) in the cloth clamp mercerizer, and the speed is 30m / min; then carry out printing processing; the composition of the printing paste used is: Corning Chemical Co., Ltd. 138 paste 45-60%, urea 2%, ammonium sulfate 2.5%, neutral dyes: DyStar 2S-LD black, NHF-S yellow, NHF-S blue 9.54, MBW green; vat d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com