Method for dyeing linen fabric/fibres by reduced dye at high temperature

A hemp fabric and dye technology, applied in dyeing, textile and paper making, etc., can solve the problems of self-decomposition or other side reactions, over-reduction, poor dyeing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

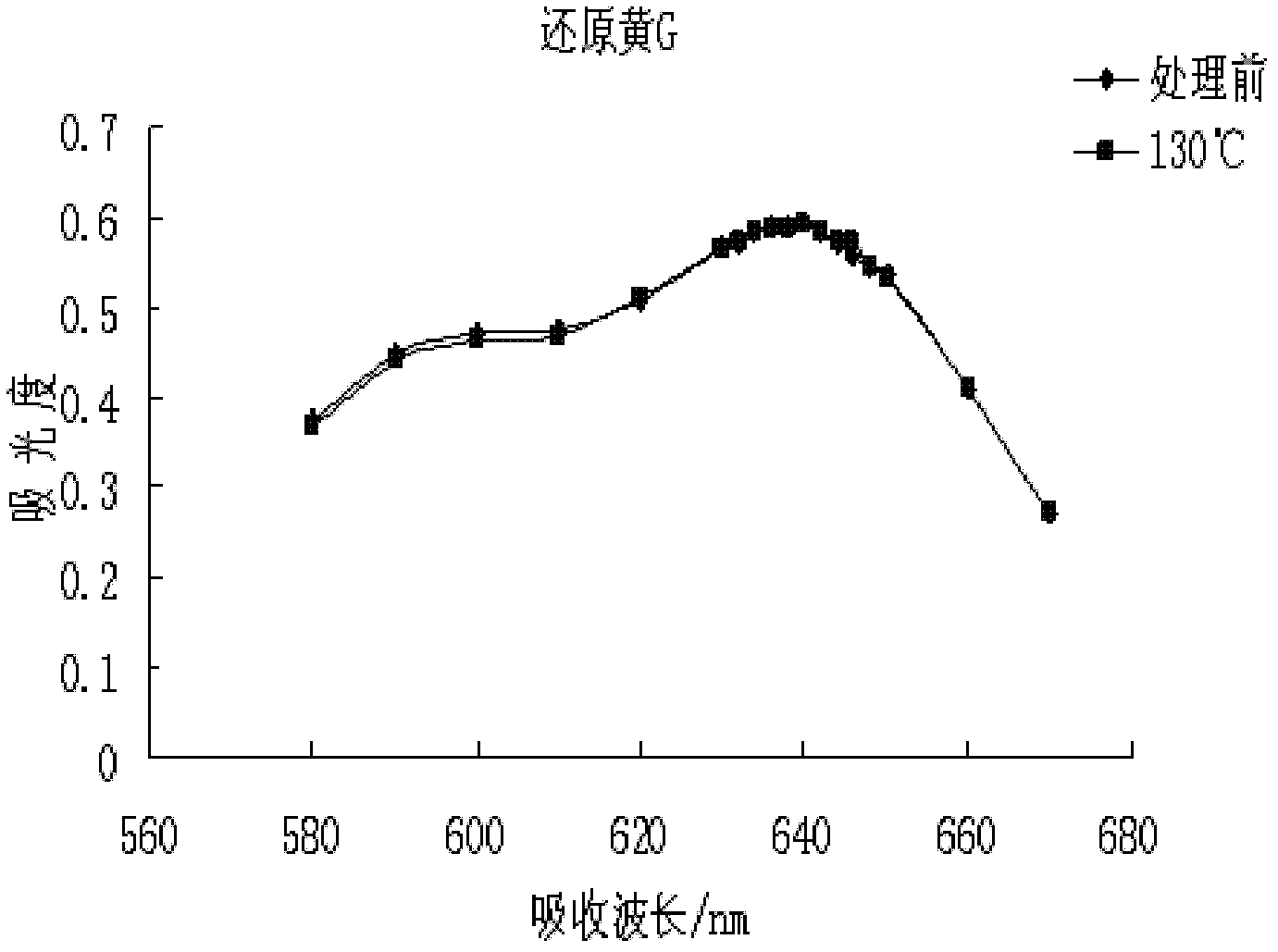

[0017] Embodiment 1: the high-temperature dyeing process of vat yellow G:

[0018] Add 6g / L hydrosulfite and 2g / L NaOH to 0.1g / L vat yellow G dispersion, fully reduce at 50°C, then raise the temperature to 130°C at a rate of 5°C / min, and keep it warm After 10 min, cool down to room temperature. The absorption curves of leucosome solution of reduced yellow G before and after high temperature treatment are as follows: figure 1 shown. It can be seen that the absorption curve of vat yellow G is basically unchanged before and after high temperature treatment, so vat yellow G is suitable for high temperature dyeing.

[0019] The dyeing of vat yellow G to hemp fabric: according to the bath ratio of 1:40, the dye that will be 5% by weight to the fabric, the sodium hydroxide of 40g / L, the sodium hydroxide of 20g / L, prepare vat yellow G in the dyeing vat suspension. After sealing, heat up to 70°C and reduce for 10 minutes. Then add the hemp fabric, reseal it, heat it up to 110°C at...

Embodiment 2

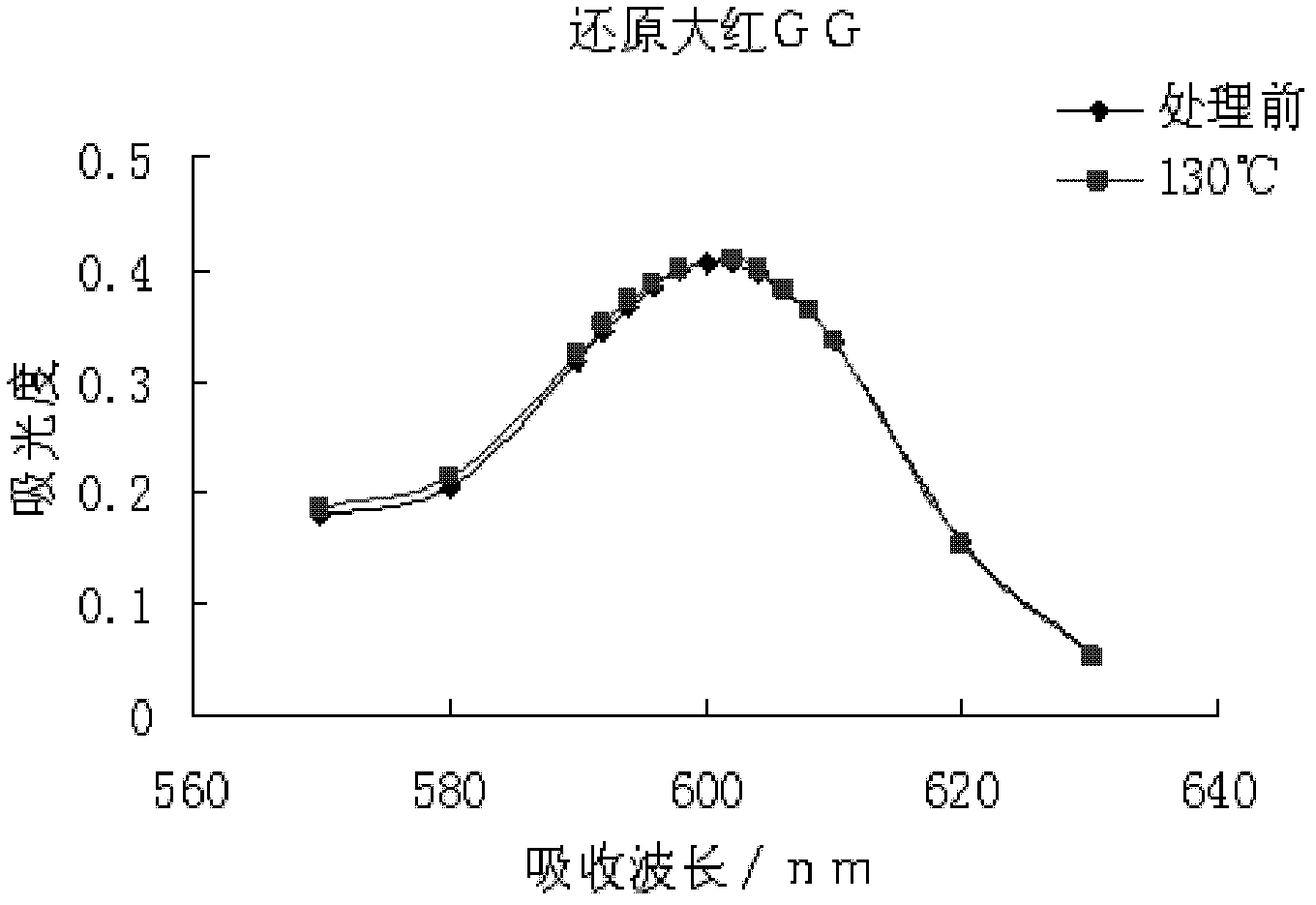

[0020] Embodiment 2: the high-temperature dyeing process of reduced bright red GG:

[0021] Raise the temperature of the reduced scarlet GG solution, which has been fully reduced by sodium sulfide in the presence of NaOH, to 130°C at a rate of 5°C / min, keep it warm for 10 minutes, and then cool down to room temperature. The absorption curves of the reduced scarlet GG leucosome solution before and after high temperature treatment are as follows: figure 2 shown. It can be seen that the absorption curve of reduced scarlet GG is basically unchanged before and after high temperature treatment, so reduced scarlet GG is suitable for high temperature dyeing.

[0022] Dyeing of hemp fabric with vat scarlet GG: according to the bath ratio of 1:40, the dye that is 5% of the fabric weight, 40g / L of hydrosulfite, and sodium hydroxide of 20g / L are prepared in the dyeing vat to prepare vat scarlet GG suspension. After sealing, heat up to 70°C and reduce for 15 minutes. Then add the hemp...

Embodiment 3

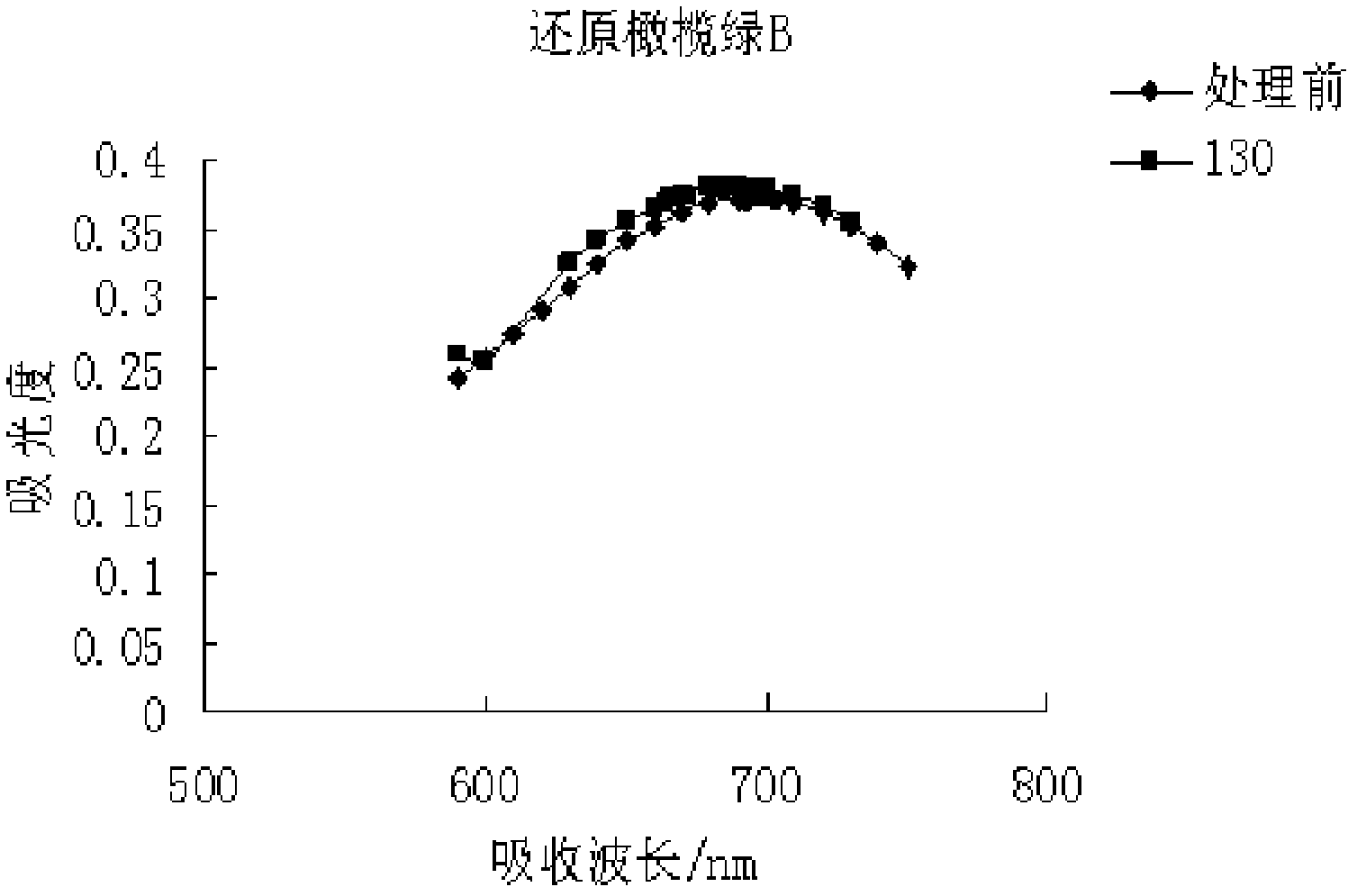

[0023] Example 3: Dyeing Cannabis with Reduced Olive Green B

[0024] Raise the temperature of the reduced olive green B solution that has been fully reduced by sodium sulfide in the presence of NaOH to 130°C at a rate of 5°C / min, keep it warm for 10 minutes, and then cool down to room temperature. The absorption curves of the reduced olive green B leucosome solution before and after high temperature treatment are as follows: image 3 shown. It can be seen that the absorption curve of reduced olive green B is basically unchanged before and after high temperature treatment, so reduced olive green B is suitable for high temperature dyeing.

[0025] The dyeing of reduced olive green B to hemp fabric: according to the bath ratio of 1: 40, will be the dyestuff that is 5% by weight to fabric, the sodium hydroxide of 30g / L, the sodium hydroxide of 25g / L, prepare reduced olive green B in the dyeing vat suspension. After sealing, heat up to 70°C and reduce for 15 minutes. Then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com