Dyeing device for cloth production

A dyeing device and fabric technology, which is applied in the processing of textile materials, processing textile material drums, processing textile material carriers, etc., can solve problems such as increasing operating costs, reducing production efficiency, and incomplete dyeing, and shortening drying time. , Improve work efficiency, dyeing thoroughly and comprehensively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

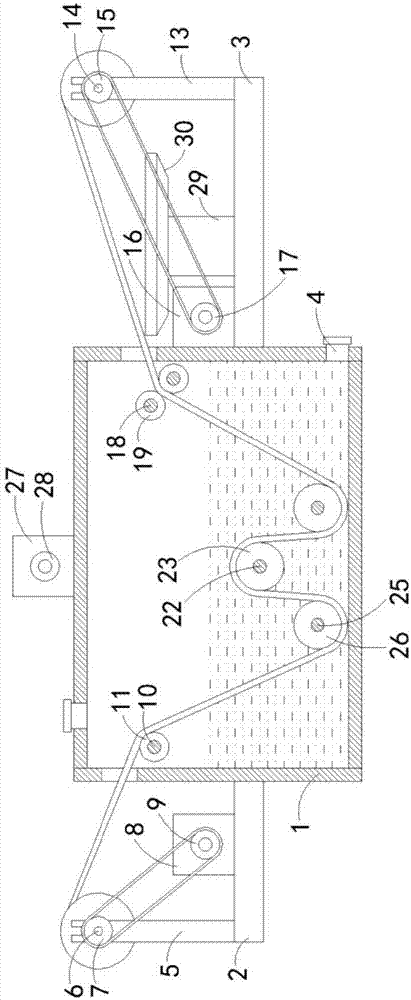

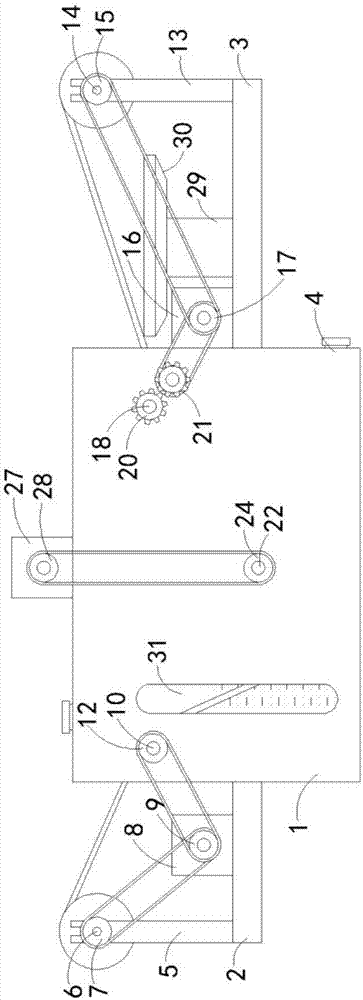

[0021] Such as Figure 1-2 As shown, a dyeing device for fabric production includes a box body 1. It is worth mentioning that a vertical strip-shaped opening is provided on the side wall of the box body 1, and a transparent plate 31 is installed in the strip-shaped opening. The box body The left and right side walls of 1 are respectively fixedly connected with the first horizontal plate 2 and the second horizontal plate 3, the upper end of the first horizontal plate 2 is provided with a feeding mechanism, and the upper end of the second horizontal plate 3 is provided with a discharge mechanism and a drying mechanism. Mechanism, specifically, the drying mechanism includes a hot air blower 29 installed on the upper surface of the second horizontal plate 3. The air outlet of the hot air blower 29 is equipped with a guide cover 30, and the hot air blown by the hot air blower 29 can dry the cloth passing through from above. Drying, the left and right side walls of the box body 1 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com