Automatic wig dyeing machine

A dyeing machine, automatic technology, applied in the direction of wigs, textile processing machine accessories, clothing, etc., can solve the problems of high price of automatic dyeing machines, tangled hair products, insufficient dyeing, etc., to improve the quality of hair dyeing and ensure good health. , the effect of a good working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

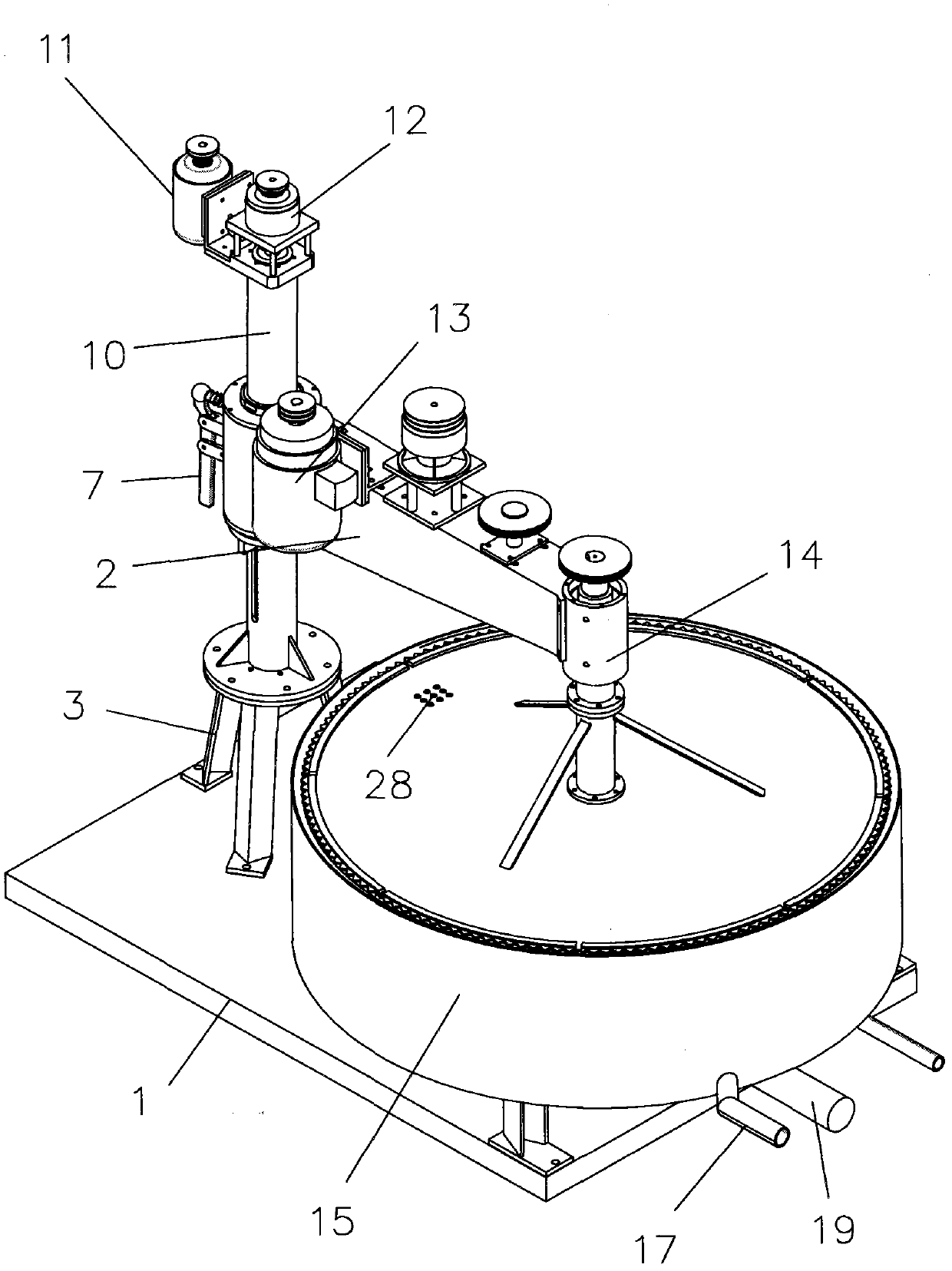

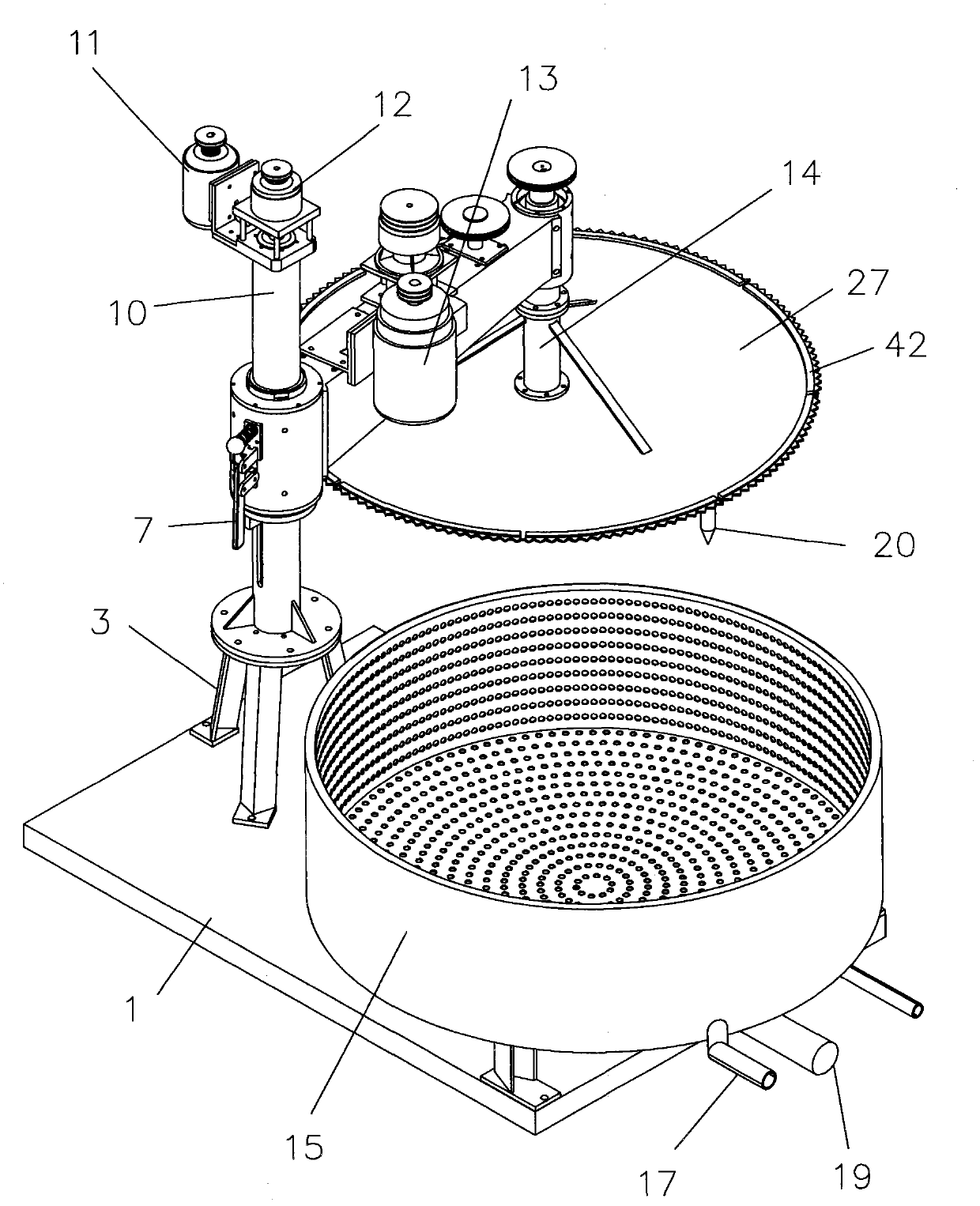

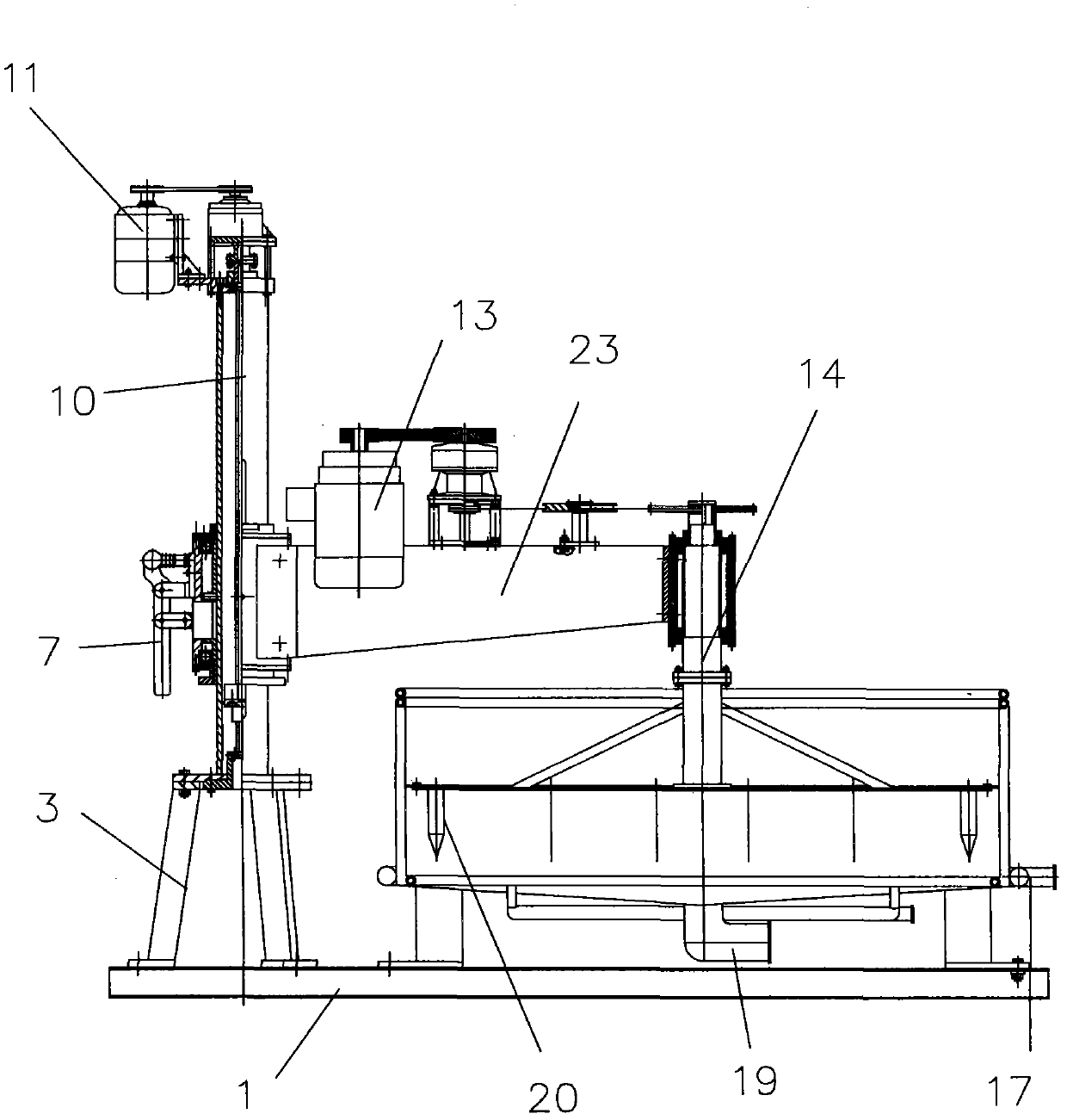

[0029] to combine Figure 1 to Figure 9 , the preferred embodiments of the present invention will be described in further detail.

[0030] Such as figure 1 As shown, an automatic wig dyeing machine mainly involves components including a base 1 , a tripod 3 , a cantilever mechanism 2 , a stirring mechanism 14 , a lifting mechanism 10 and a barrel body 15 .

[0031] The barrel body 15 and the tripod 3 are located on the base 1 . The lifting mechanism 10 is installed on the tripod 3 to provide lifting power for the cantilever mechanism 2. The lifting motion power of the system is provided by the driving motor 11 positioned at the top of the lifting mechanism 10. The driving motor 11 is connected to the speed reducer 12, and through the speed reducer 12 through the joint The shaft device transmits the power on the reducer to the leading screw 22 of the lifting mechanism 10 .

[0032] Lifting mechanism 10 such as Figure 4 , mainly includes the parts guide post 21, leading scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com