Processing method of vest

A processing method and technology for vests, applied in the field of garment processing, can solve the problems of single color and style of vests, low efficiency, waste of labor, etc., and achieve the effects of improving drying efficiency and printing and dyeing efficiency, reducing manual operations, and improving printing and dyeing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0035] A method for processing a vest, the method comprising the following steps: a, printing and dyeing, printing and dyeing the vest fabric to be processed through a printing and dyeing device before the vest processing; b, drying, drying the fabric through a drying room after the fabric is printed and dyed c, dust removal, the fabric is dedusted by the dedusting device after the fabric is dried; d, cutting, the dedusted fabric is cut into vest parts by the cutting device; e, sewing, the vest parts after cutting are sewed by the sewing device, Be processed into a complete vest; f, collect, collect the prepared vest through a collecting device.

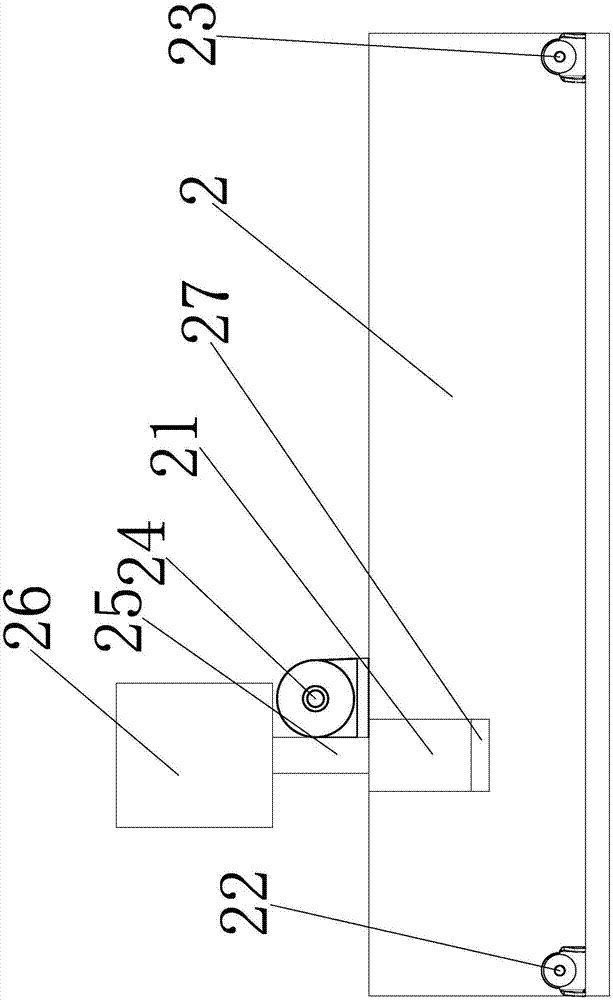

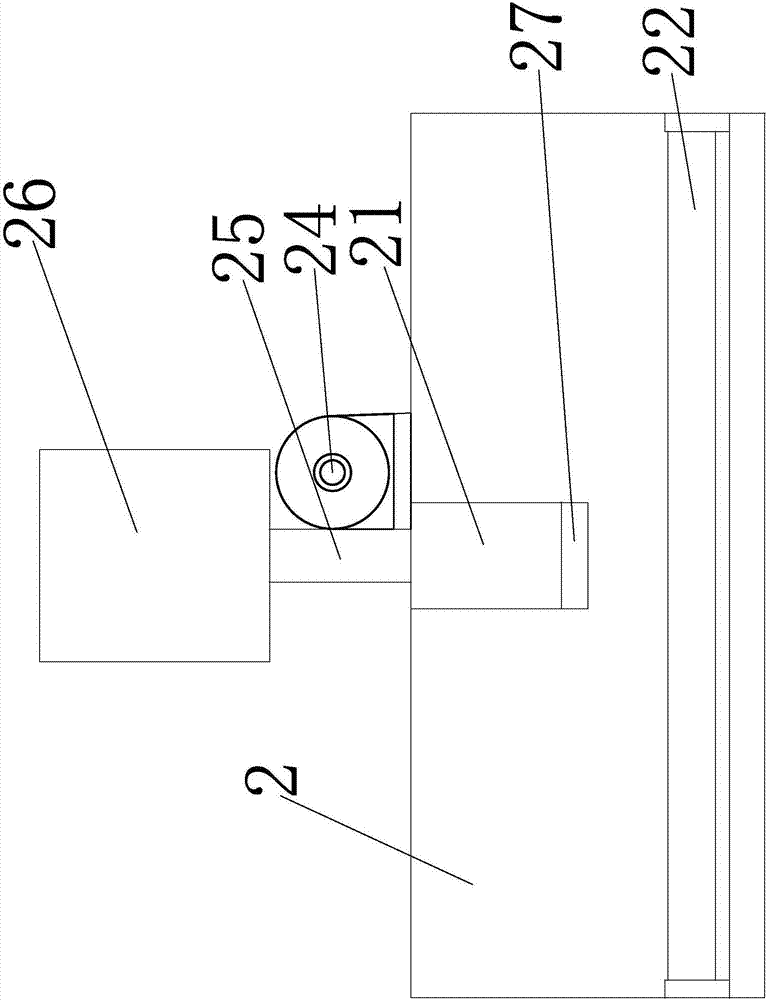

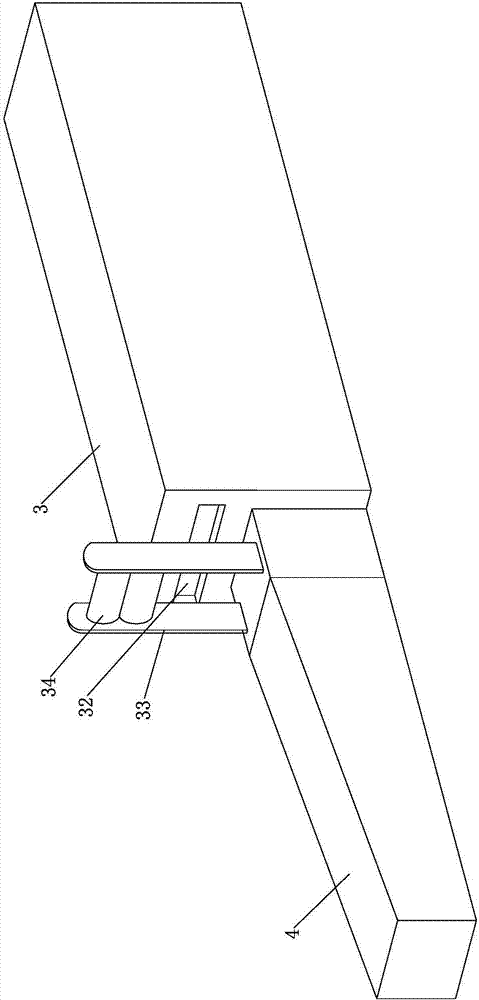

[0036] Such as figure 1 , figure 2 As shown, the printing and dyeing devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com