Textile fabric printing and dyeing equipment and printing and dyeing method

A technology for textile fabrics and printing and dyeing equipment, which is applied in the processing of textile material equipment configuration, textile material processing, and textile material carrier processing. It can solve the problems of poor printing and dyeing uniformity, improve uniformity, improve air-drying quality, and reduce emission pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

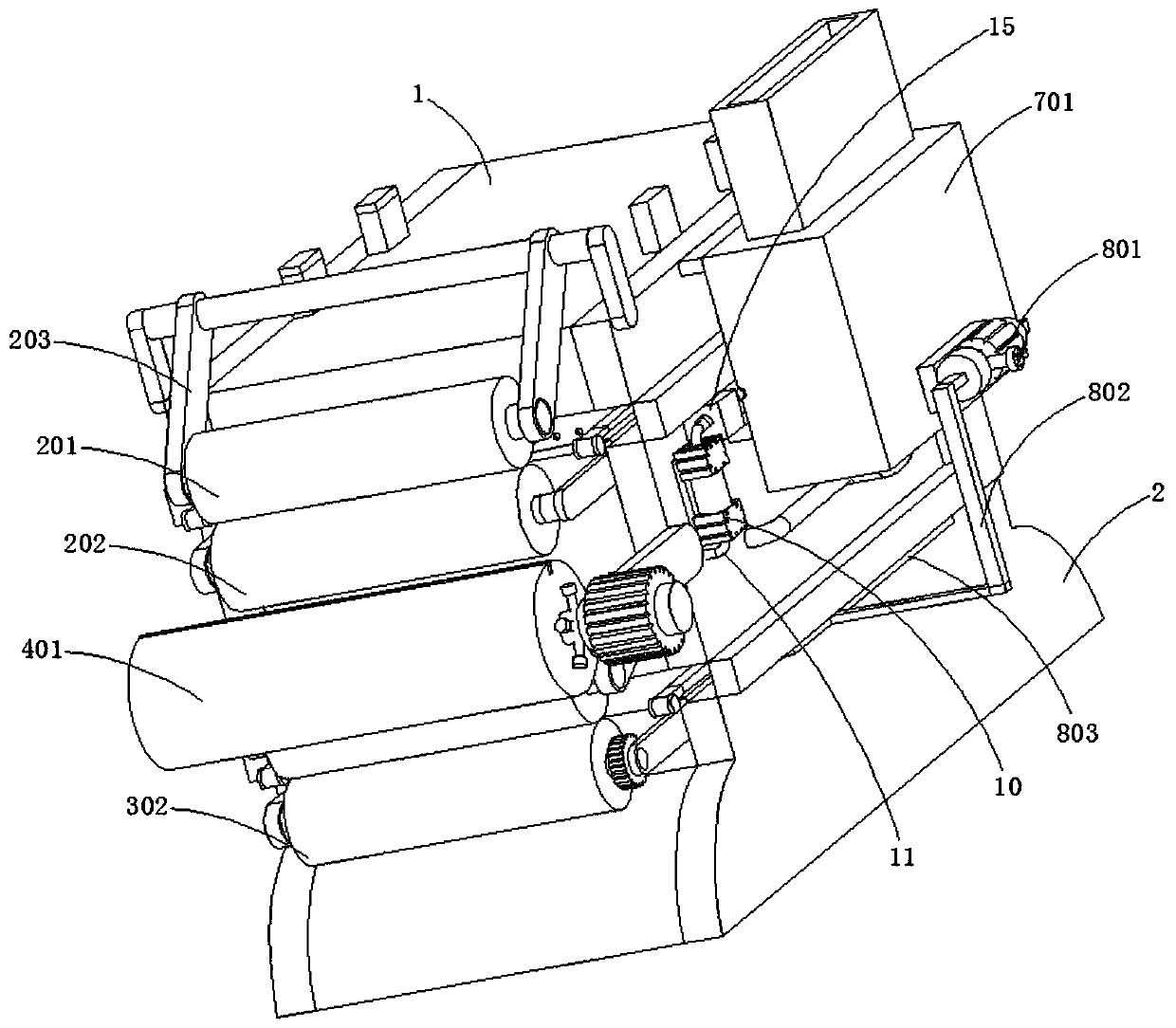

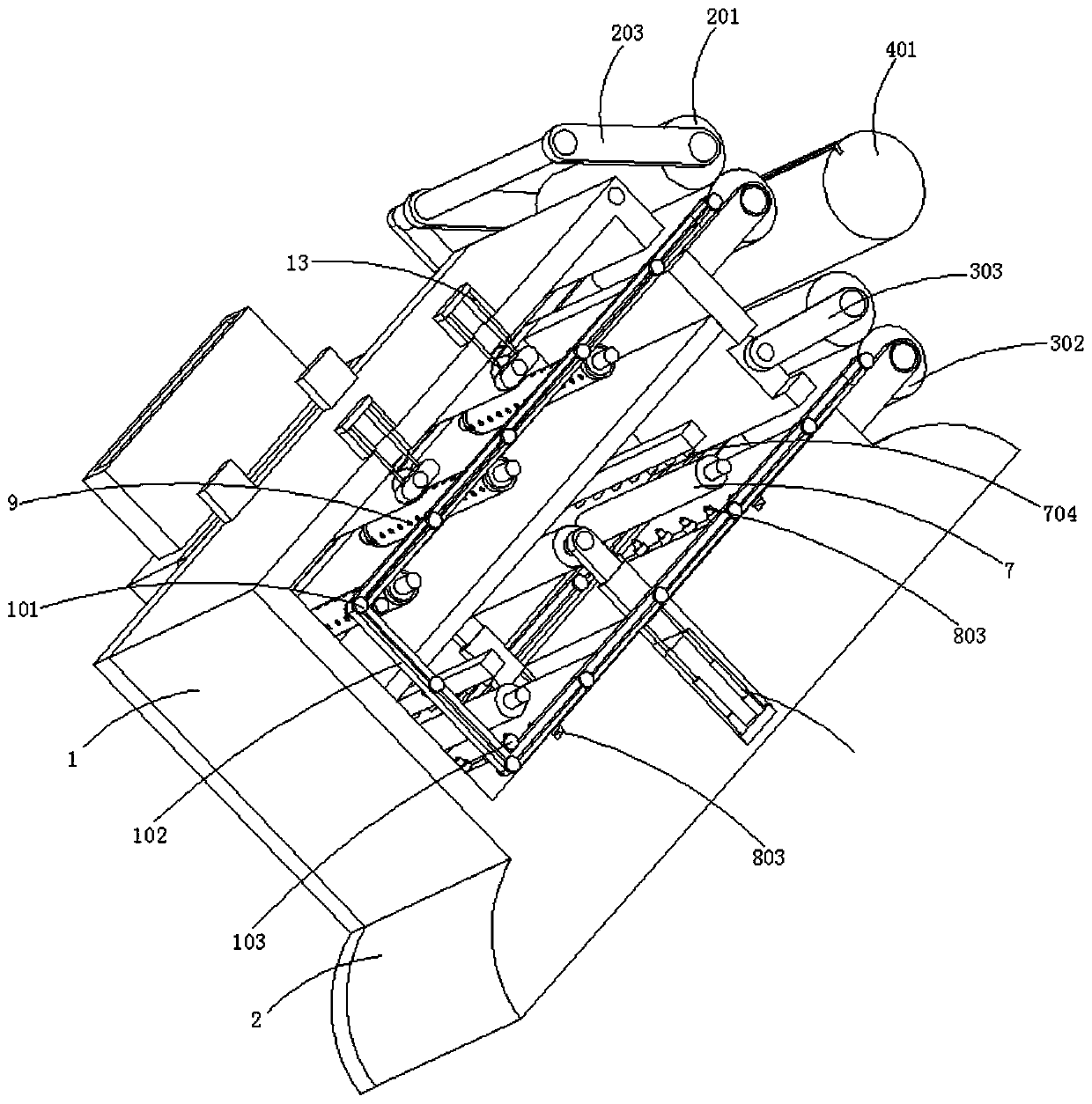

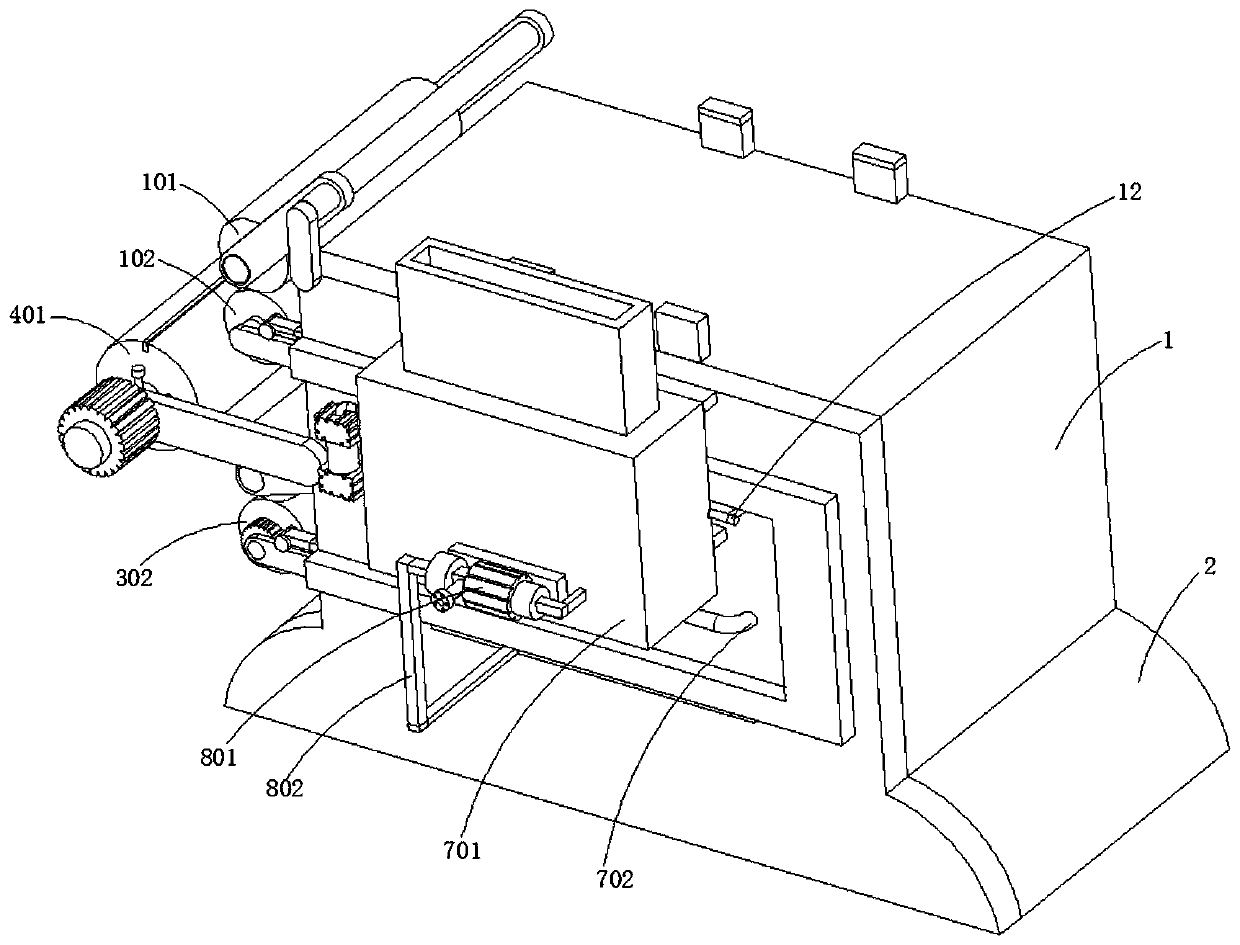

[0036] refer to Figure 1-7 , a textile fabric printing and dyeing equipment and printing and dyeing method, comprising a box 1 and a base 2, the inner wall of the box 1 is provided with a partition 3, the partition 3 is provided with a reserved groove, and the box 1 is divided into upper and lower parts by the partition 3 In the drying room and the lower printing and dyeing room, one side of the box body 1 is provided with a material inlet 4 and a material outlet 5 respectively connected with the upper drying room and the lower printing and dyeing room along the vertical direction, and the inner wall of the box body 1 is provided with symmetrically distributed Pre-traction mechanism, and the two ends of the pre-traction mechanism pass through the feed port 4, the reserved groove and the discharge port 5 respectively, and the outer wall of the box body 1 is provided with a drying mechanism, a winding mechanism and a smoothing mechanism in sequence along the vertical direction. ...

Embodiment 2

[0043] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 6 , a textile fabric printing and dyeing equipment and a printing and dyeing method, which are basically the same as in Example 1, furthermore, the drying mechanism is mainly composed of a first driven roller 201 and a first driving roller 202, and the first driven roller 201 passes through the first The movable arm 203 is rotatably connected to the top bracket of the casing 1, the first driving roller 202 is fixedly connected to the outer side wall of the casing 1 through a connecting rod, the first driven roller 201 is placed above the first driving roller 202, and the first Both the outer walls of the driving roller 202 and the first driven roller 201 are provided with an electric heating layer 204;

[0044] The cloth fixing part 6 is mainly composed of a first fixing plate 601 and a second fixing plate 602, the two ends of the first fixing plate 601 are connected with needles 603, and the two ends ...

Embodiment 3

[0048] refer to Figure 1-4 , a textile fabric printing and dyeing equipment and a printing and dyeing method, which are basically the same as in Example 1, furthermore, the drying mechanism is mainly composed of a first driven roller 201 and a first driving roller 202, and the first driven roller 201 passes through the first The movable arm 203 is rotatably connected to the top bracket of the casing 1, the first driving roller 202 is fixedly connected to the outer side wall of the casing 1 through a connecting rod, the first driven roller 201 is placed above the first driving roller 202, and the first Both the outer walls of the driving roller 202 and the first driven roller 201 are provided with an electric heating layer 204;

[0049] The smoothing mechanism is mainly composed of a second driven roller 301 and a second driving roller 302, the second driven roller 301 is rotatably connected to the side wall of the box body 1 through the second movable arm 303, and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com