Dye stirring device of fabric dyeing equipment

A printing and dyeing equipment and stirring device technology, applied in the field of machinery, can solve the problems of no heating device, influence of printing and dyeing quality, low activity of dyes, etc., to reduce the contact area, accelerate the speed of activity increase, and improve the effect of printing and dyeing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

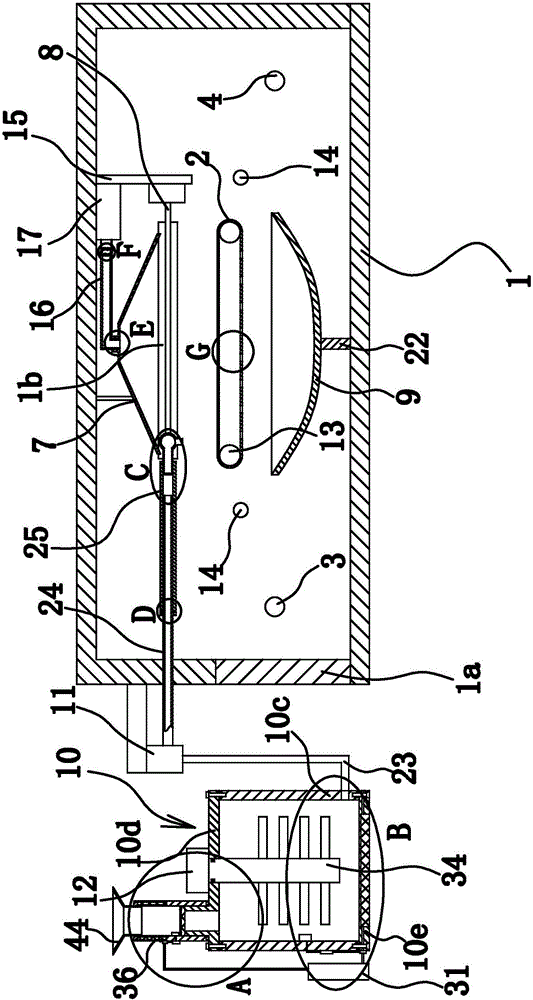

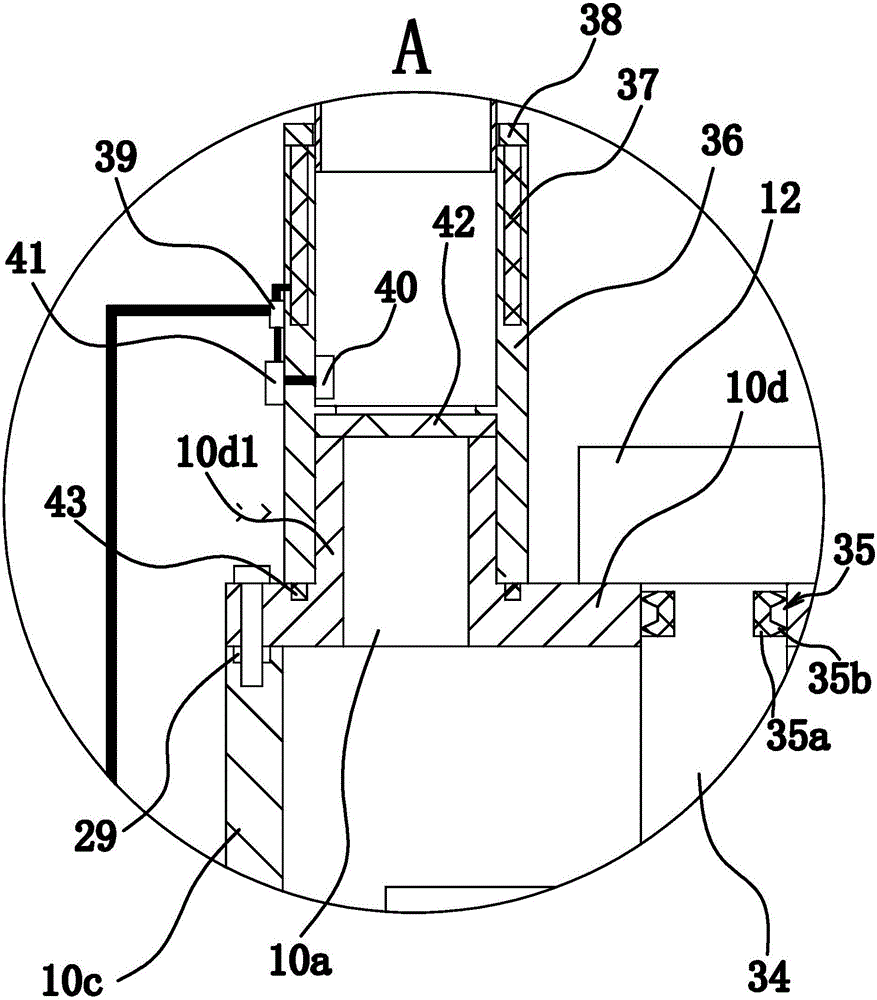

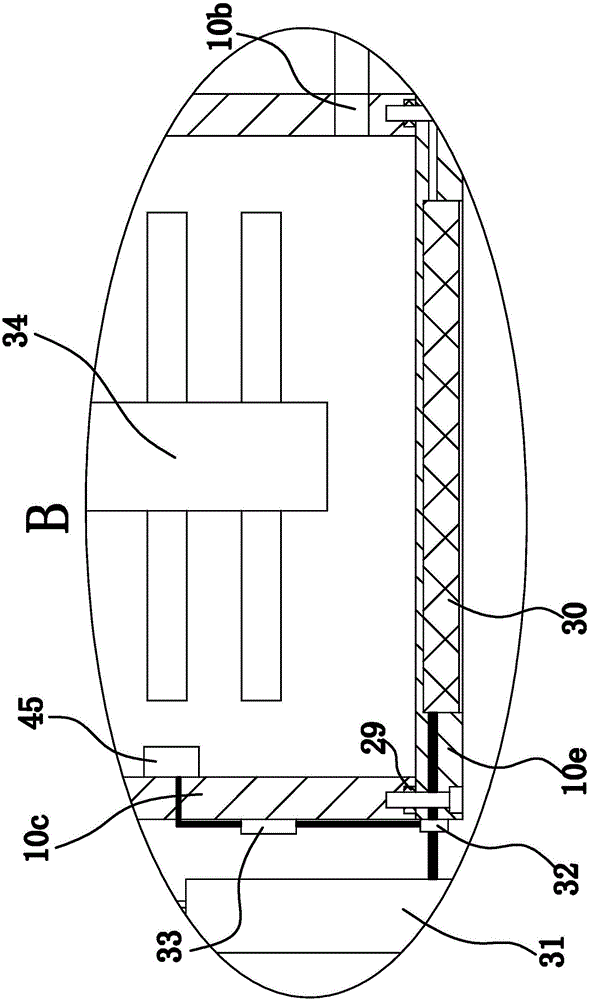

[0031] Such as Figure 1 to Figure 9 As shown, the fabric printing and dyeing equipment consists of a printing and dyeing room 1, a conveyor belt 2, a discharge roller 3, a winding roller 4, a liquid outlet pipe 5, a nozzle 6, a gas outlet 7, an air supply mechanism, a driving part 8, and a windshield 9 , Stirring box 10, pumping machine 11, motor 12, connectors and other components.

[0032] Wherein, one side of the printing and dyeing room 1 is provided with a doorway for operators to enter and exit, and a door panel 1a is hinged at the doorway. Two conveying rollers 13 are axially fixed in the printing and dyeing room 1 , and the two conveying rollers 13 are located opposite each other, and one of the conveying rollers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com