Textile fabric printing and dyeing method

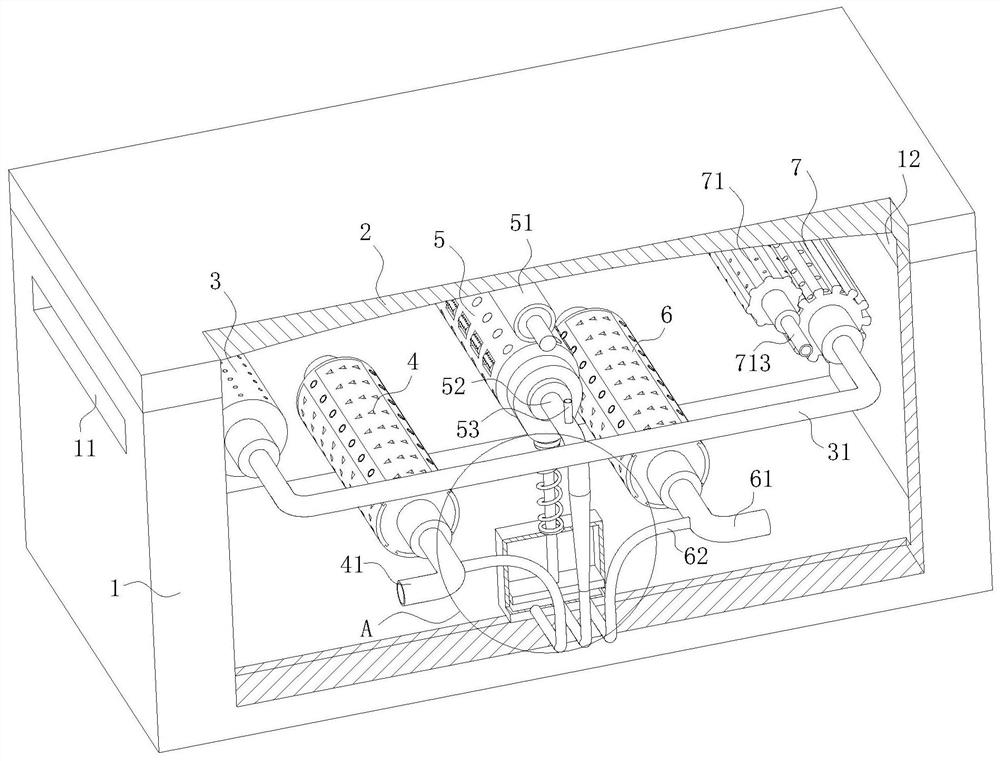

A technology of textile fabrics and fabrics, which is applied to the processing of textile materials, the processing of textile material drums, and the fixing of chemicals in textile materials. Effects that enhance effects and deepen color depth and richness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

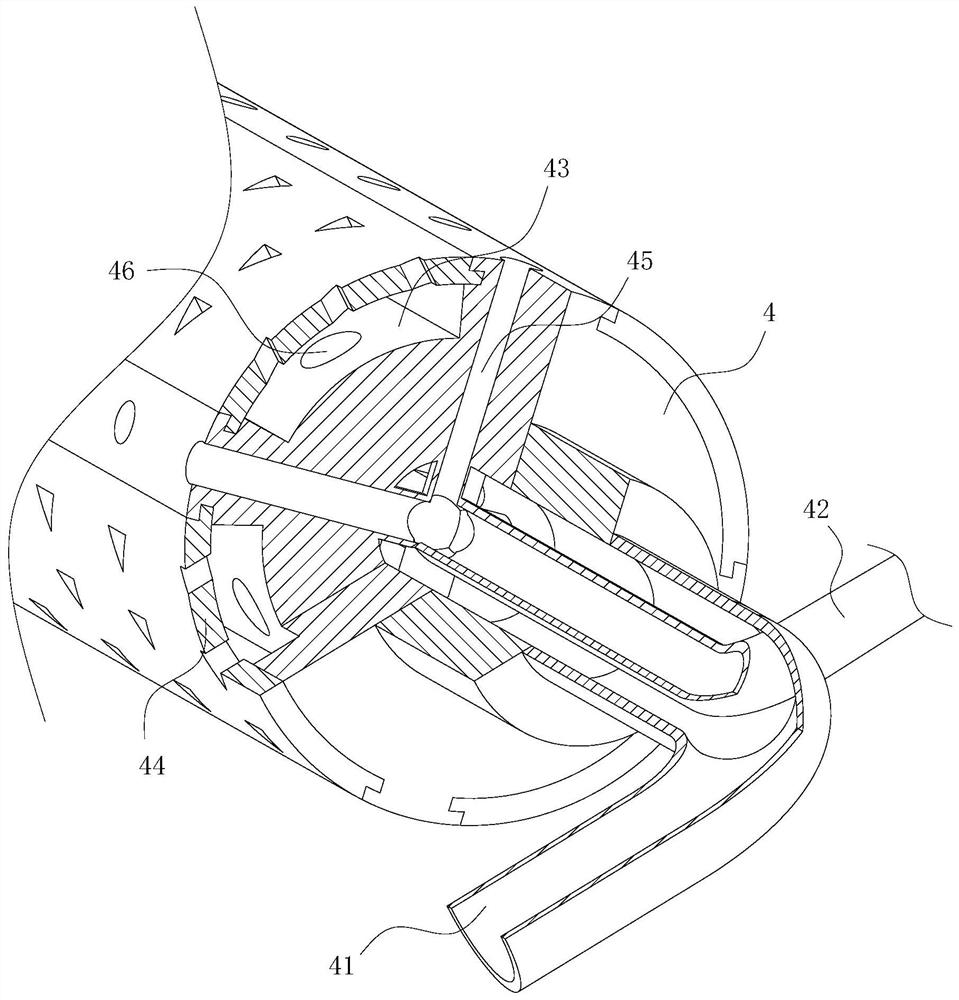

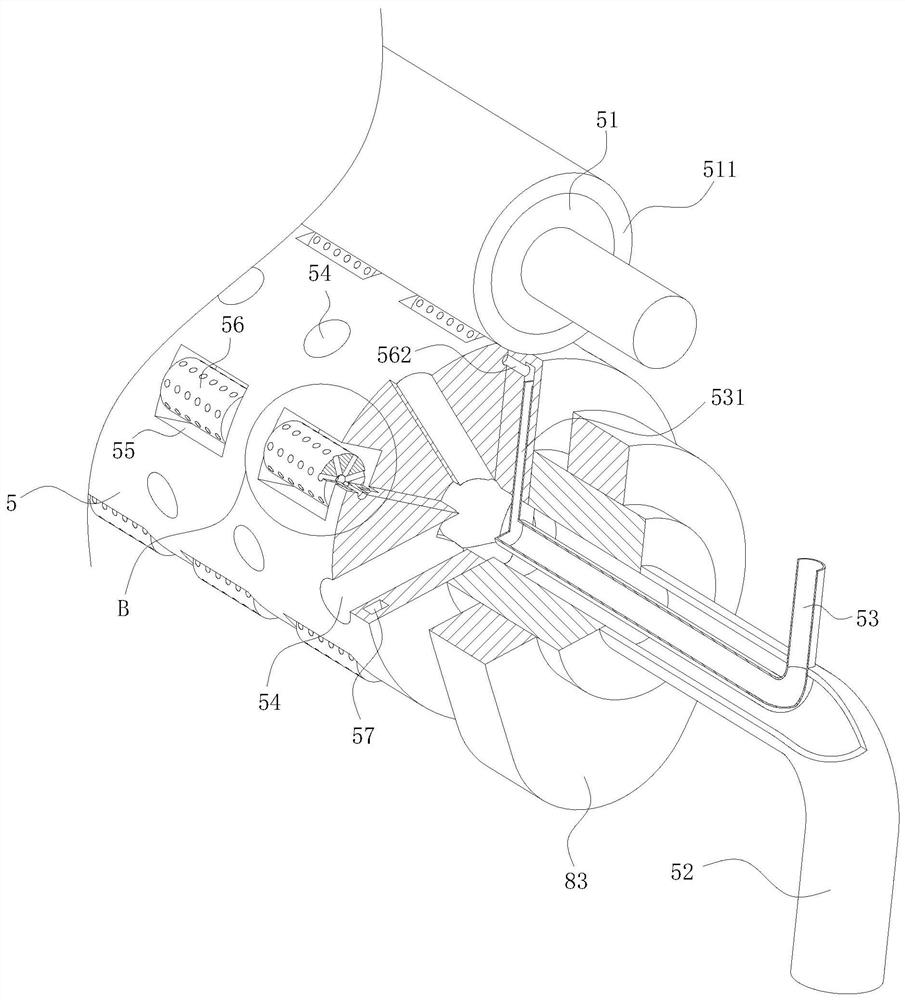

[0038] As an embodiment of the present invention, a squeeze roller 51 is installed on the main body 1; the squeeze roller 51 is located directly above the middle roller 5, and the squeeze roller 51 is in close contact with the middle roller 5; The surface of the roller 51 is covered with a sponge layer 511; the surface of the intermediate roller 5 is uniformly provided with a through hole 4 54; the inside of the intermediate roller 5 is provided with a cavity 2; the through hole 4 54 communicates with the cavity 2; Pipe four 52 is installed on the intermediate roller 5; the pipe four 52 communicates with cavity two; a cam 83 is installed on the rotating shaft of the intermediate roller 5; a box body 8 is installed in the main body 1; Movable plate 84 is installed in body 8; Keep sealing between described movable plate 84 and box body 8; Movable bar 81 is installed on described movable plate 84; The top of described movable bar 81 contacts with cam 83; A spring 82 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com