Flash dyeing production method for textiles

A production method and textile technology, applied in the flash dyeing production field of textiles, can solve the problems of dark colors with many floating colors, long production process flow, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, without limiting their rights.

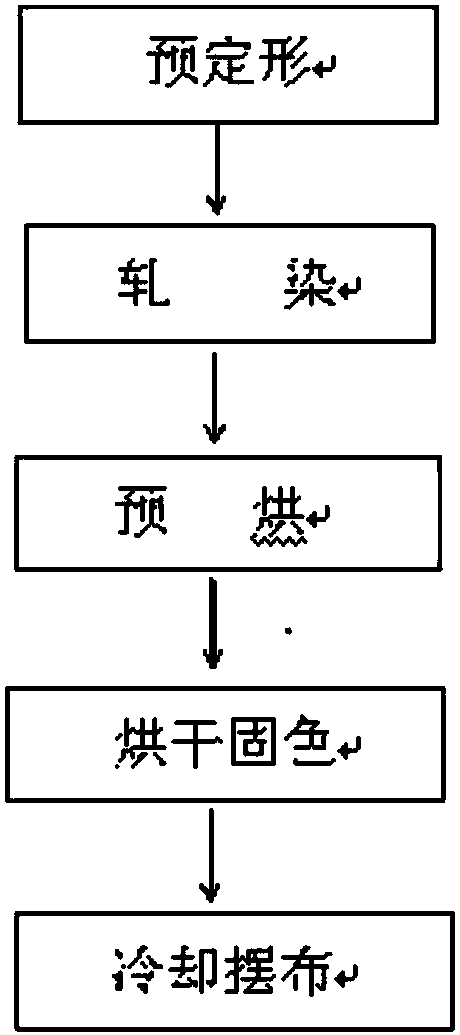

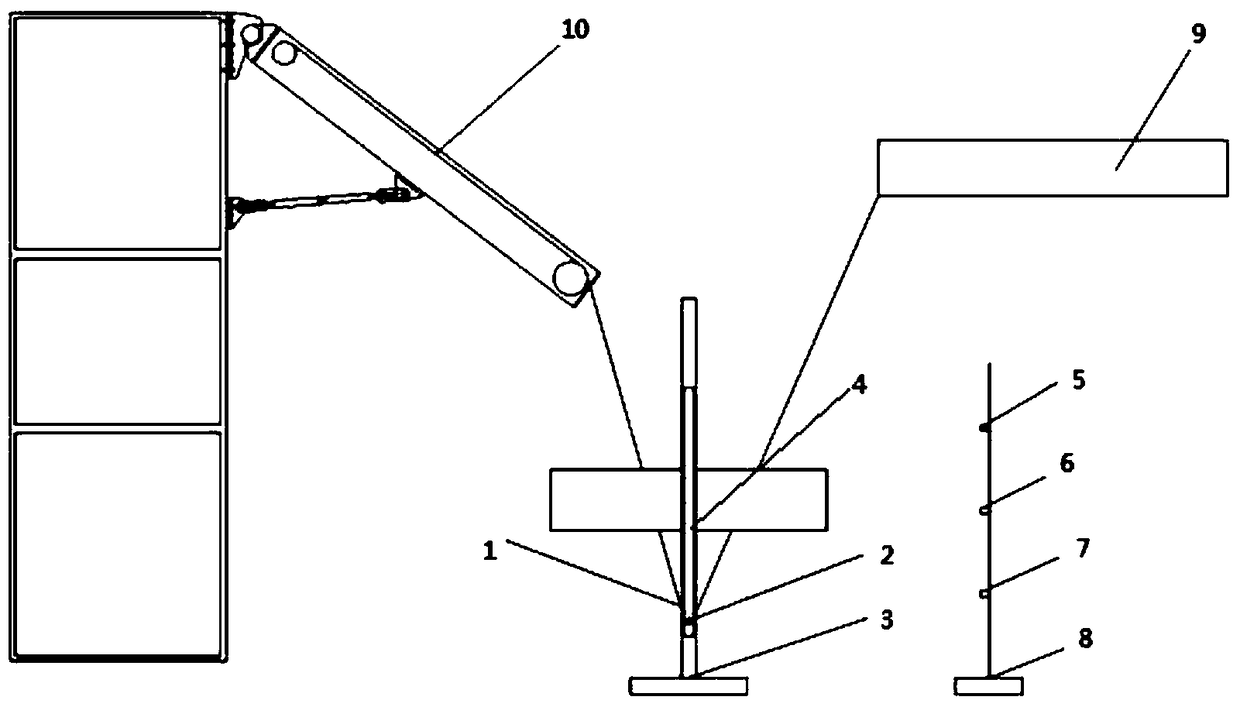

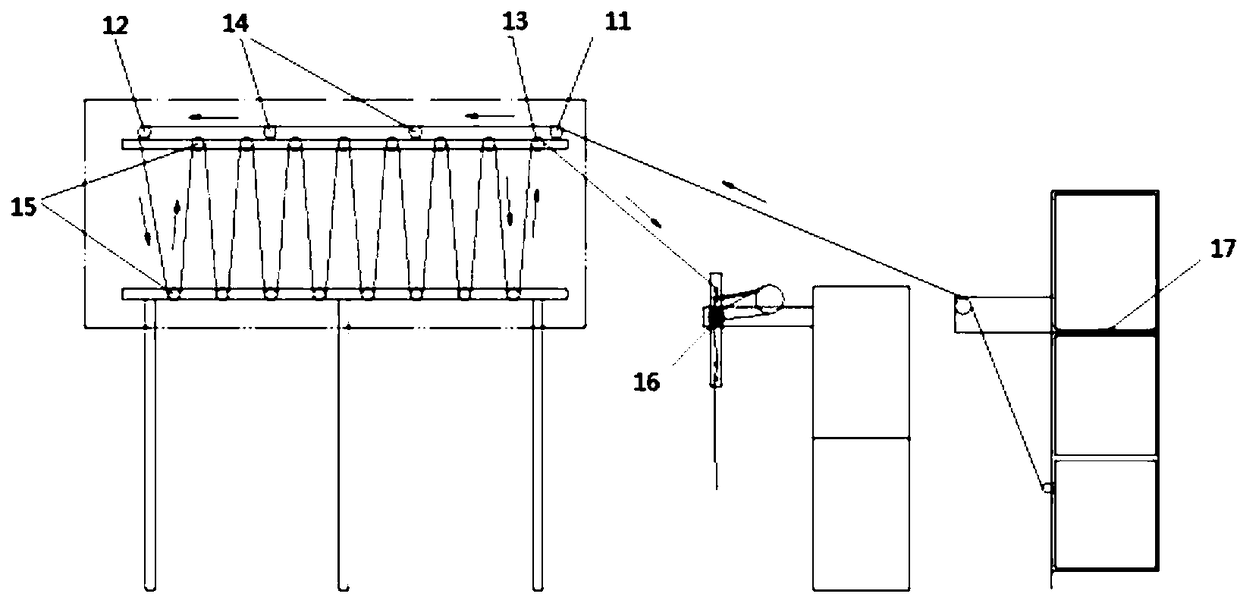

[0028] A flash dyeing production method for textiles. The woven fabric is fed into the oven of a pre-setting machine at a speed of 30-200m / min by a cloth feeding frame, and the fabric is subjected to dry heat treatment at a temperature of 150°C-230°C for 10 -120 seconds, let the fiber expand under high temperature conditions, remove more than 80% of the oil agent, control the oil-water content of the fabric below 0.8%, export it from the oven, and cool the fabric below 45°C through the cooling device to stabilize the fabric shape. Through the cloth storage tank between the pre-shape and the pad dyeing unit, it enters the pad dyeing unit to perform padding and flash dyeing dyeing solution on the fabric. The excess rate of the fabric is controlled at 20-80%, and it enters the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com