Device and method for the treatment, in particular electrolysis or cleaning, of endless fibers, threads or webs of fabric

A technology of fibers, threads, applied in the field of baths and methods for processing, in particular for electrolysis or for cleaning continuous fibres, threads or fabrics, capable of solving problems of increased cost, uneven flow, difficult implementation, etc., Achieve the effect of increasing the residence time and reducing the external size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

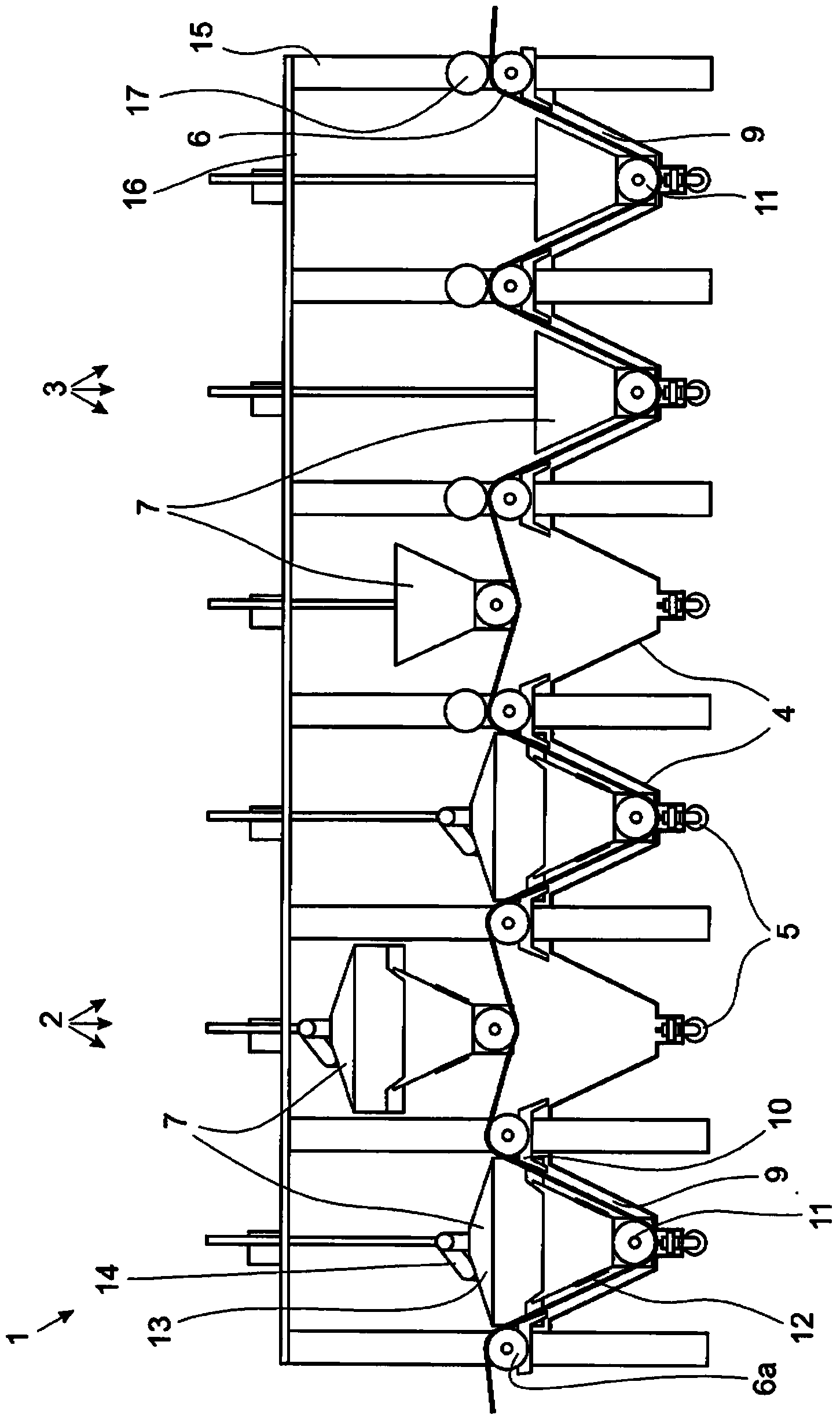

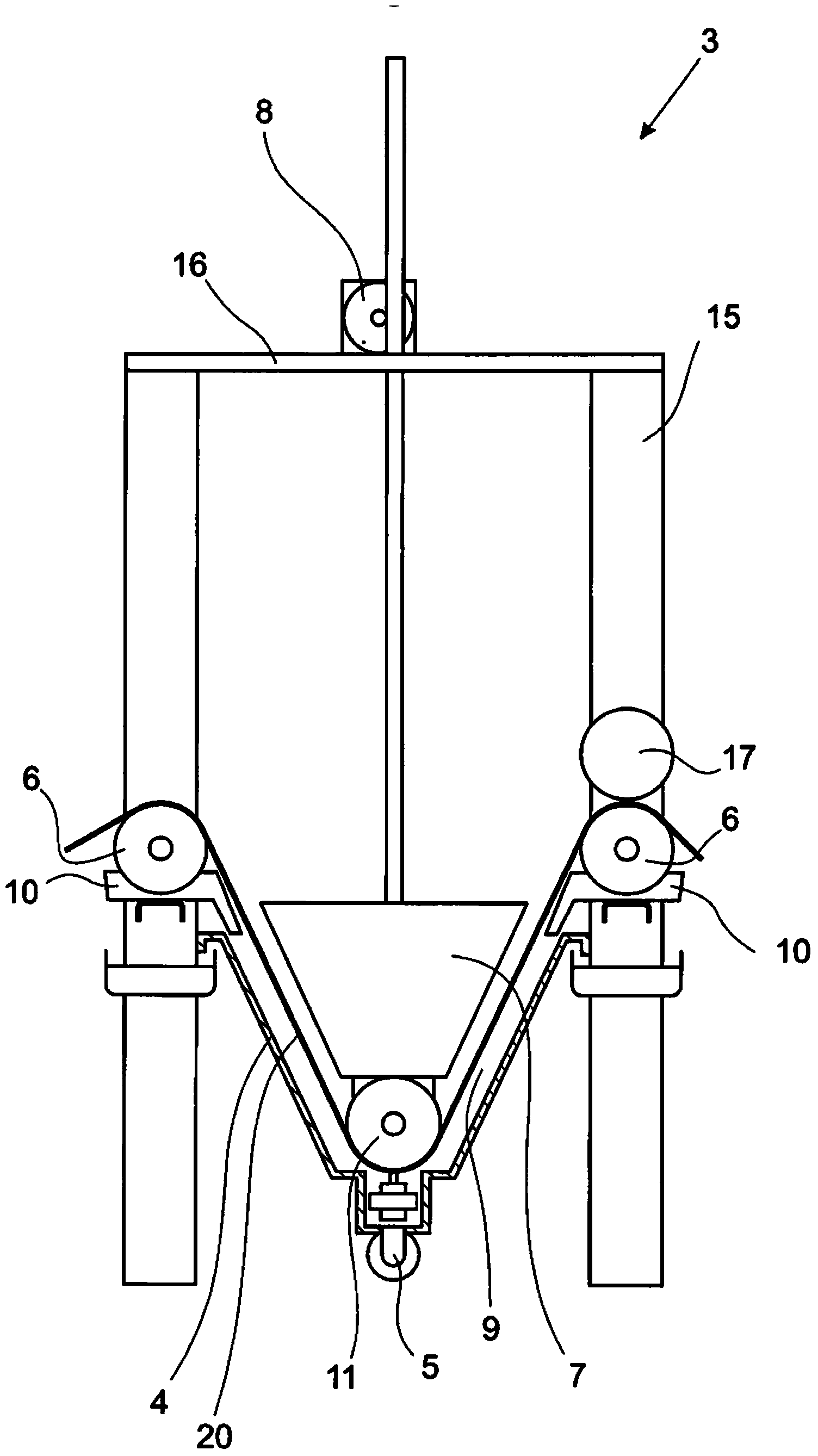

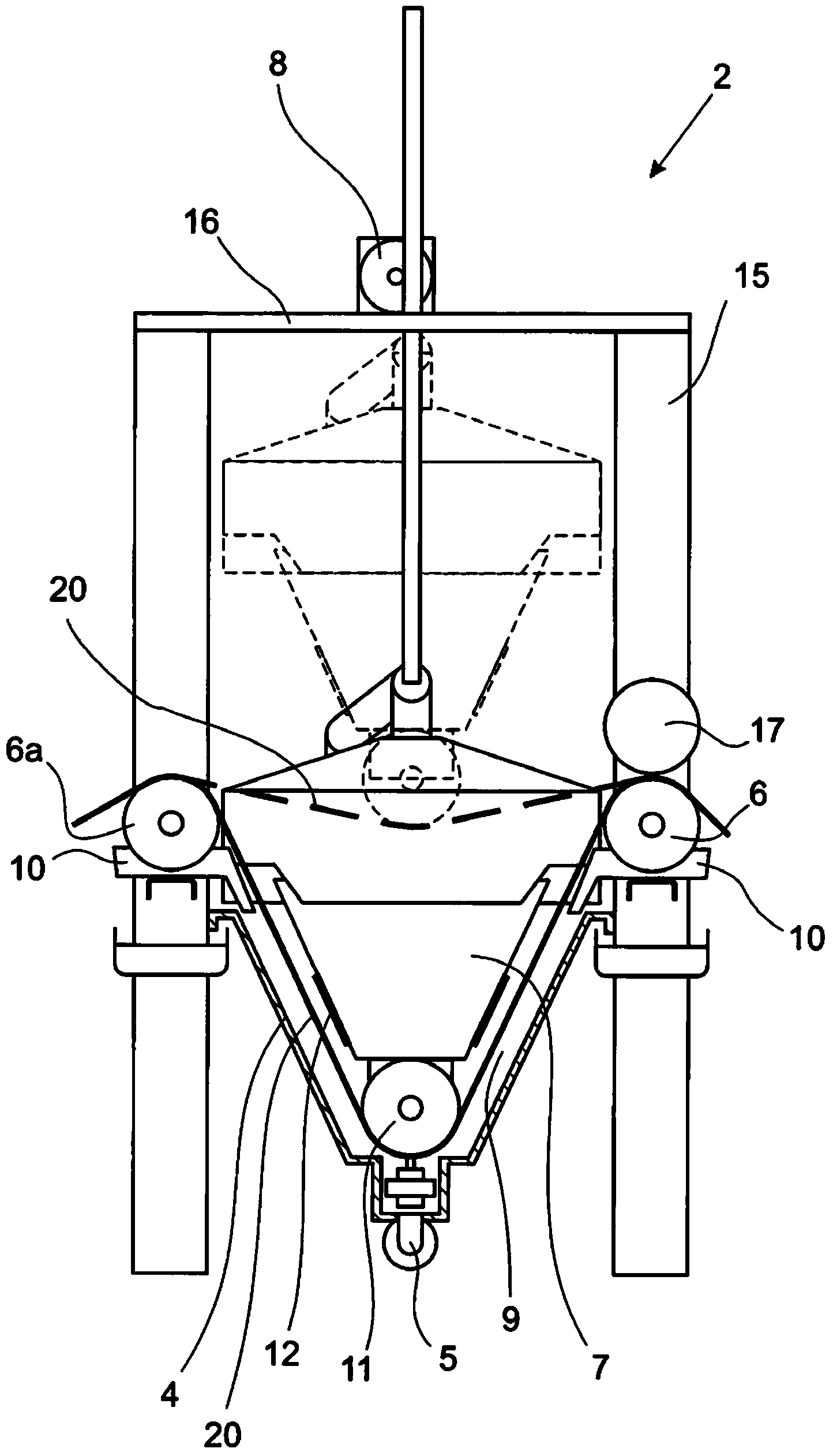

[0030] exist figure 1 An apparatus 1 for treating continuous fibres, threads or fabrics is shown, which also includes a combined electrolysis and washing bath. The combined electrolysis and washing bath can be part of an overall plant in which, for example, continuous fibers made of synthetic material are carbonized. Thus, for example, a storage and / or pulling device is arranged upstream of the combined electrolysis and washing bath, and a winding device is arranged behind it.

[0031] In the exemplary embodiment, the combined electrolysis and washing bath comprises three successive electrolysis baths 2 and three successive washing baths 3 connected thereto. The baths 2 , 3 can be arranged one behind the other in a modular fashion, wherein a part of the vertical support 15 can be supported by itself or in combination with the support of the next bath 2 , 3 . It is obvious that, depending on the material to be processed, any other number of electrolysis and / or washing baths 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com