Method for fixing colors of textiles and device thereof

A technology for textiles and color-fixing liquid, which is applied in textiles and papermaking, textile material processing, and textile material fixing chemicals, etc., can solve difficult and complicated problems, achieve convenient operation, simple equipment and process, and remarkable color fixing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

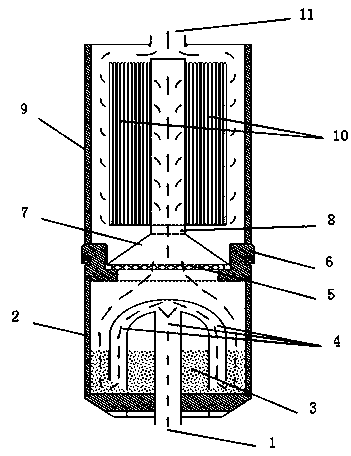

[0020] See attached figure 1 , which is a structural schematic diagram of a color-fixing processing device for textiles provided in this embodiment. It includes a color-fixing liquid storage tank, a color-fixing tank and a supercritical carbon dioxide fluid treatment system with a circulation pump. The belt circulation system is omitted in the figure. Pumps for supercritical carbon dioxide fluid handling systems.

[0021] The color-fixing liquid storage kettle 2 is a cylindrical cavity with an inverted "mountain" type tubular fluid distributor 4 inside, which is composed of three interconnected pipes, with the mouth of the pipe bent downward, and two of the pipes are circulating fluid The outlet pipe, the pipeline located in the center is the circulating fluid inlet pipe 1, which communicates with the supercritical carbon dioxide fluid system through the opening at the lower end of the color-fixing liquid storage tank, and the color-fixing liquid storage tank and the color-fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com