Production process for silver ion antibacterial knitted fabric

A knitted fabric and production process technology, applied in the field of knitted fabric production, can solve problems such as unsatisfactory antibacterial properties, and achieve excellent color fastness and antibacterial properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

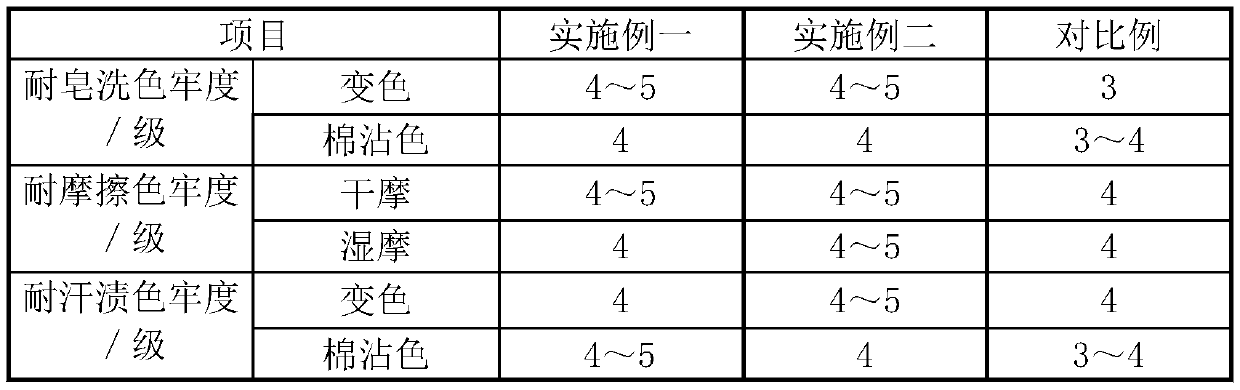

[0026] The production process of a kind of silver ion antibacterial knitted fabric involved in the present embodiment comprises the following steps: S1 preparation of spun silk raw sliver, S2 drawing frame, S3 roving, S4 adopting Sirofil spinning process to prepare spun silk nylon filament composite yarn , S5 preparation of knitted fabrics, S6 washing, S7 pretreatment, S8 dyeing, S9 color fixing and S10 washing and drying. And adding silver ion antibacterial agent during dyeing can make the fabric have excellent antibacterial performance and can maintain antibacterial performance for a long time.

[0027] In the preparation of step S1 spun silk sliver, combed cotton balls are used, and the length of spun silk fiber is not less than 5.5cm, and the short fiber ratio below 3cm is not more than 10%; the spun silk sliver is formed after stretching and sliver making. The combed cotton balls used are required to be clean and white, with good luster, cleanliness greater than or equal ...

Embodiment 2

[0038] The production technology of a kind of silver ion antibacterial knitted fabric involved in the present invention comprises the following steps: S1 preparation of spun silk raw sliver, S2 drawing frame, S3 roving, S4 adopting Sirofil spinning process to prepare spun silk nylon filament composite yarn, S5 preparation of knitted fabrics, S6 washing, S7 pretreatment, S8 dyeing, S9 color fixing and S10 washing and drying. And adding silver ion antibacterial agent during dyeing can make the fabric have excellent antibacterial performance and can maintain antibacterial performance for a long time.

[0039] In the preparation of step S1 spun silk sliver, combed cotton balls are used, and the length of spun silk fiber is not less than 5.5cm, and the short fiber ratio below 3cm is not more than 10%; the spun silk sliver is formed after stretching and sliver making. The combed cotton balls used are required to be clean and white, with good luster, cleanliness greater than or equal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com