Fixation machine and fixation process

A color fixing machine and color section technology, which is applied in the fields of fixing chemicals for textile materials, textiles and papermaking, and liquid/gas/steam textile material treatment, etc., which can solve the problems of energy consumption, poor production site and color fixing effect, and large occupation, etc. problems, to achieve the effect of maintaining effective humidity, shortening the time of steaming and fixing color, and accelerating the color fixing reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

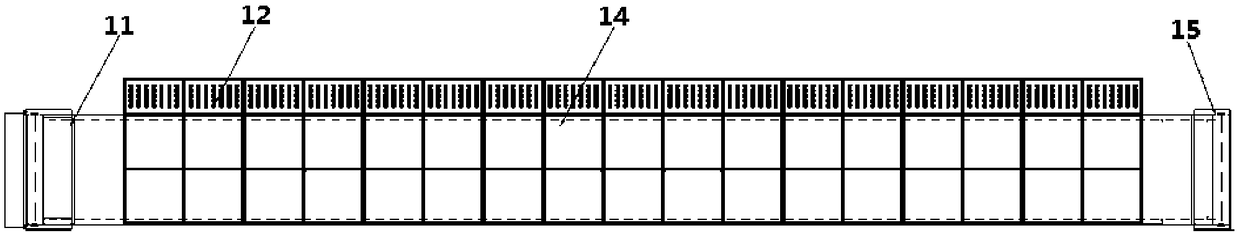

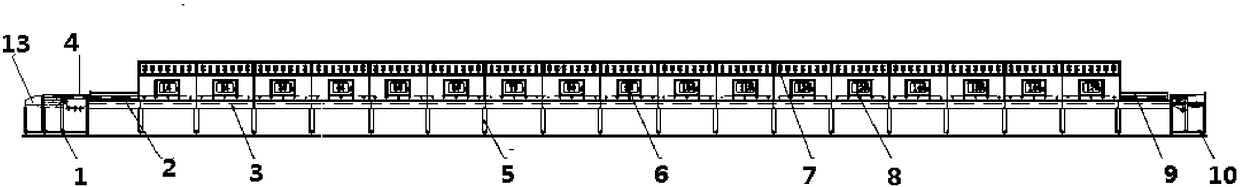

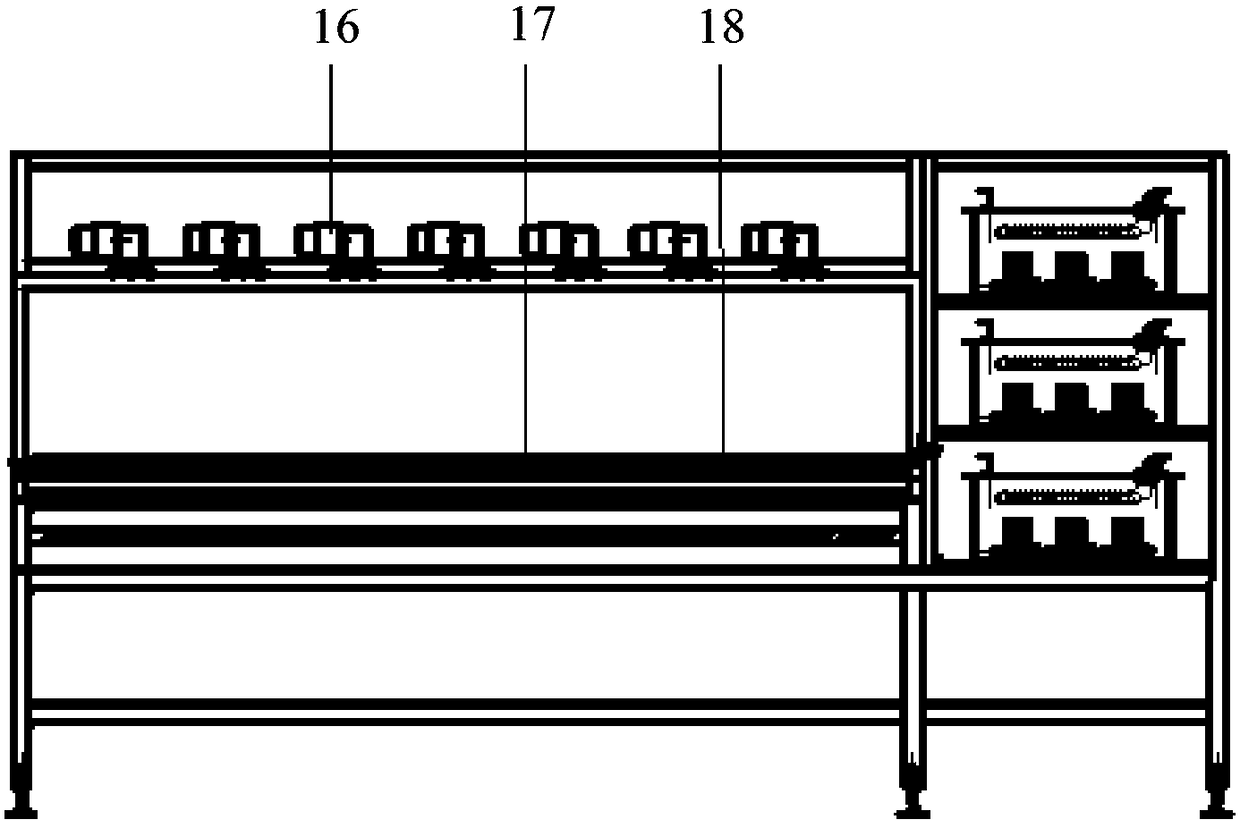

[0028] Please refer to Figure 1-3 , the embodiment of the present invention discloses a color fixing machine, and the disclosed color fixing machine includes a cloth inlet section, a cloth fixing section and a cloth outlet section 15 . Wherein, the cloth inlet section, the cloth fixing section and the cloth outlet section 15 are sequentially connected to form a moving channel for the dyed or printed cloth to advance, that is to say, the dyed cloth can pass through the cloth inlet section, the cloth fixing section and the outlet section successively. The cloth section 15 is discharged from the cloth outlet section 15 after the cloth fixing section is fixed, so as to achieve the purpose of color fixing. The cloth feeding section is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com