Emulsifying machine for environmental protection aqueous EVA treating agent

A treatment agent and emulsifier technology, applied in the field of emulsifiers, can solve the problems of no enhancement means for mixing and dissolving, single function, and ineffective guarantee of product quality, so as to speed up dispersion and emulsification, increase high-frequency vibration, and accelerate dissolution and dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

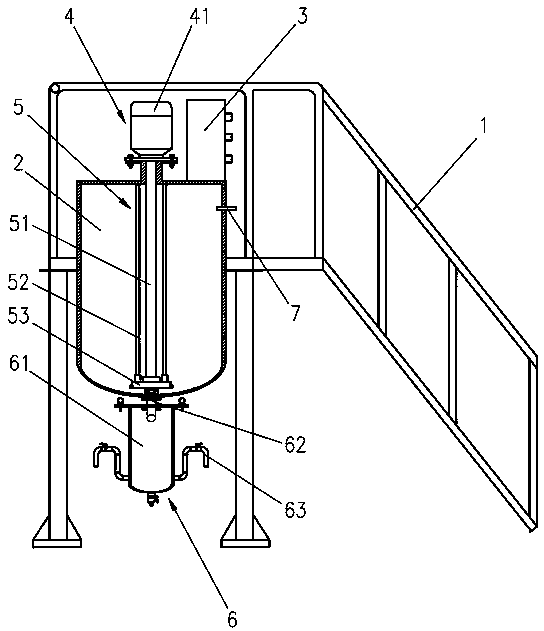

[0015] As shown in the figure, an environmentally friendly water-based EVA treatment agent emulsifier includes: a frame 1, a reaction tank 2 and a control box 3, and the reaction tank 2 and the control box 3 are fixedly installed on the frame 1. It is characterized in that: a stirring device 4 is installed on the top of the reaction tank 2 and is connected with the control box 3. The stirring device 4 is composed of a motor 41 and a stirring paddle 5 connected to the motor 41. The stirring paddle 5 is arranged inside the reaction tank 2. The stirring paddle 5 is composed of a rotating shaft 51 and a number of stirring rods 52 evenly distributed around the outside of the rotating shaft 51. The rotating shaft 51 and the stirring rods 52 are fixedly connected by a connecting plate 53; the stirring device 4 is also provided with an ultrasonic device....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com