Metal nano wire transparent conductive film and preparation method thereof

A technology of transparent conductive film and metal nanowire, applied in the direction of metal/alloy conductor, conductive material, conductive material, etc. The performance is not as good as that of metal nanowires, and the experimental conditions are easy to control, flexible development is satisfied, and the operation is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

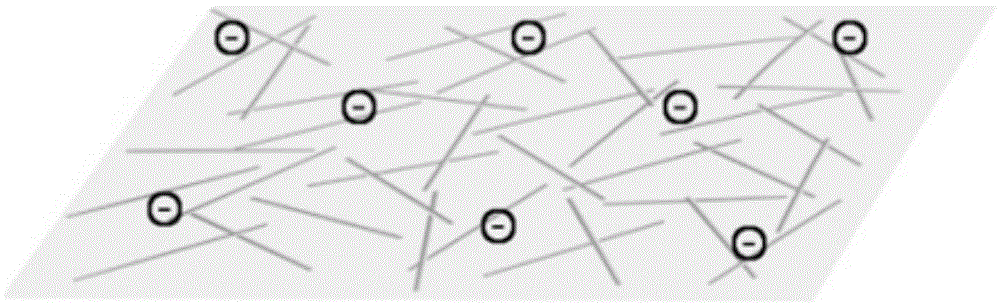

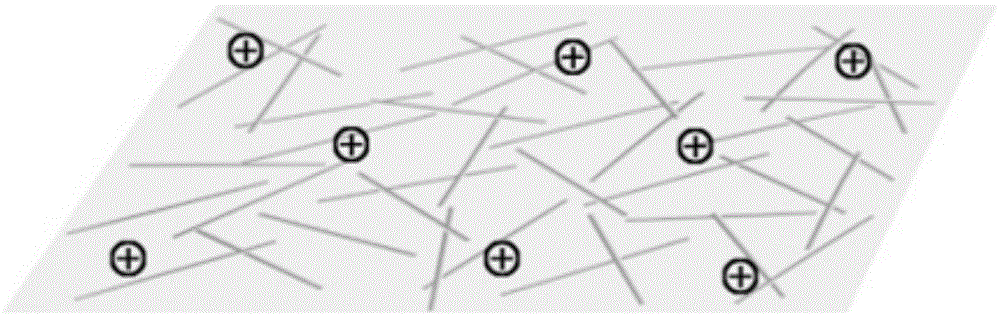

[0029] Step 1. Disperse the prepared metallic silver nanowires in ethanol to prepare 10 mg / ml metallic silver nanowires, mix them with 1 mg / ml CTAB solution, and ultrasonicate for 3 minutes after mixing to obtain positively charged metallic silver Nanowires;

[0030] Another 10 mg / ml metallic silver nanowire was mixed with 1 mg / ml SDBS solution, and then ultrasonically treated for 3 minutes after mixing to obtain negatively charged metallic silver nanowire.

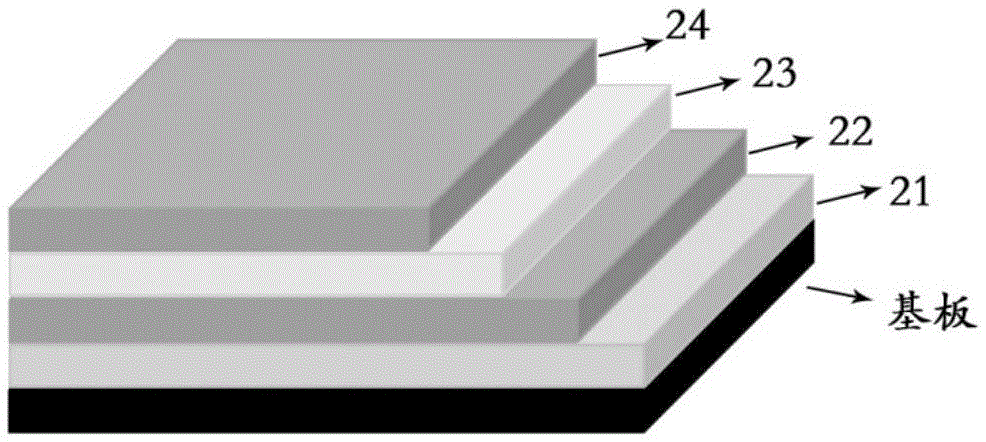

[0031] Step 2. Repeatedly ultrasonically clean the PET substrate with deionized water, ethanol, and isopropanol, and treat it with oxygen plasma for 20 minutes, and dry it with nitrogen; Slowly immerse and pull in the wire suspension, then rinse with deionized water, and then dry at 50°C for 100 min; then dip and pull the substrate in the positively charged graphene solution at the same speed, and then Rinse with deionized water, and then dry at 50°C for 100 minutes. The prepared metal nanowire anion and cation film is s...

Embodiment 2

[0034] Step 1. Disperse the prepared metallic silver nanowires in ethanol to prepare 5 mg / ml metallic silver nanowires, mix them with 1 mg / ml CTAB solution, and ultrasonicate for 3 minutes after mixing to obtain positively charged metallic silver Nanowires;

[0035] Another 5 mg / ml metallic silver nanowire was mixed with 1 mg / ml SDBS solution, and then ultrasonically treated for 3 minutes after mixing to obtain negatively charged metallic silver nanowire.

[0036] Step 2, the glass substrate is repeatedly ultrasonically cleaned with deionized water, ethanol, and isopropanol, and treated with oxygen plasma for 20 minutes, and dried with nitrogen; the negatively charged silver nanowire suspension prepared in step 1 is Spin-coat on the surface of the PET substrate at a speed of 1200 rpm, and then dry at 200°C for 1 min; then spin-coat the positively charged silver nanowire suspension prepared in step 1 on the surface of the glass substrate at the same speed, Then dry at 200°C fo...

Embodiment 3

[0039] Step 1. Disperse the prepared metallic silver nanowires in ethanol to prepare 0.01 mg / ml metallic silver nanowires, mix them with 1 mg / ml dodecyltrimethylammonium chloride solution, and mix them at 30 degrees Celsius Stir for 3 hours to obtain positively charged metallic silver nanowires;

[0040]Another 0.01 mg / ml metallic silver nanowire was mixed with 1 mg / ml SDBS solution, and stirred at 30 degrees Celsius for 3 hours after mixing to obtain electronegative metallic silver nanowire.

[0041] Step 2. Repeatedly ultrasonically clean the plexiglass substrate with deionized water, ethanol, and isopropanol, and treat it with oxygen plasma for 20 minutes, and dry it with nitrogen; suspend the negatively charged silver nanowires prepared in step 1. The solution was scraped on the surface of a clean plexiglass substrate with a Meyer rod at a speed of 1 cm / s, and then dried at 100°C for 20 minutes; then the positively charged silver nanowires prepared in step 1 were scraped o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com