Process for producing high-stability central-hole material Cu-Zn-Al2O3, and application of the same in producing mellow wine dehydrogenating catalyst

A dehydrogenation catalyst, cu-zn-al2o3 technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst carrier, oxidation to prepare carbonyl compounds, etc., can solve the problem of product yield reduction, catalyst performance improvement, thermal Poor stability and other problems, to achieve the effect of high product selectivity, good catalytic activity, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

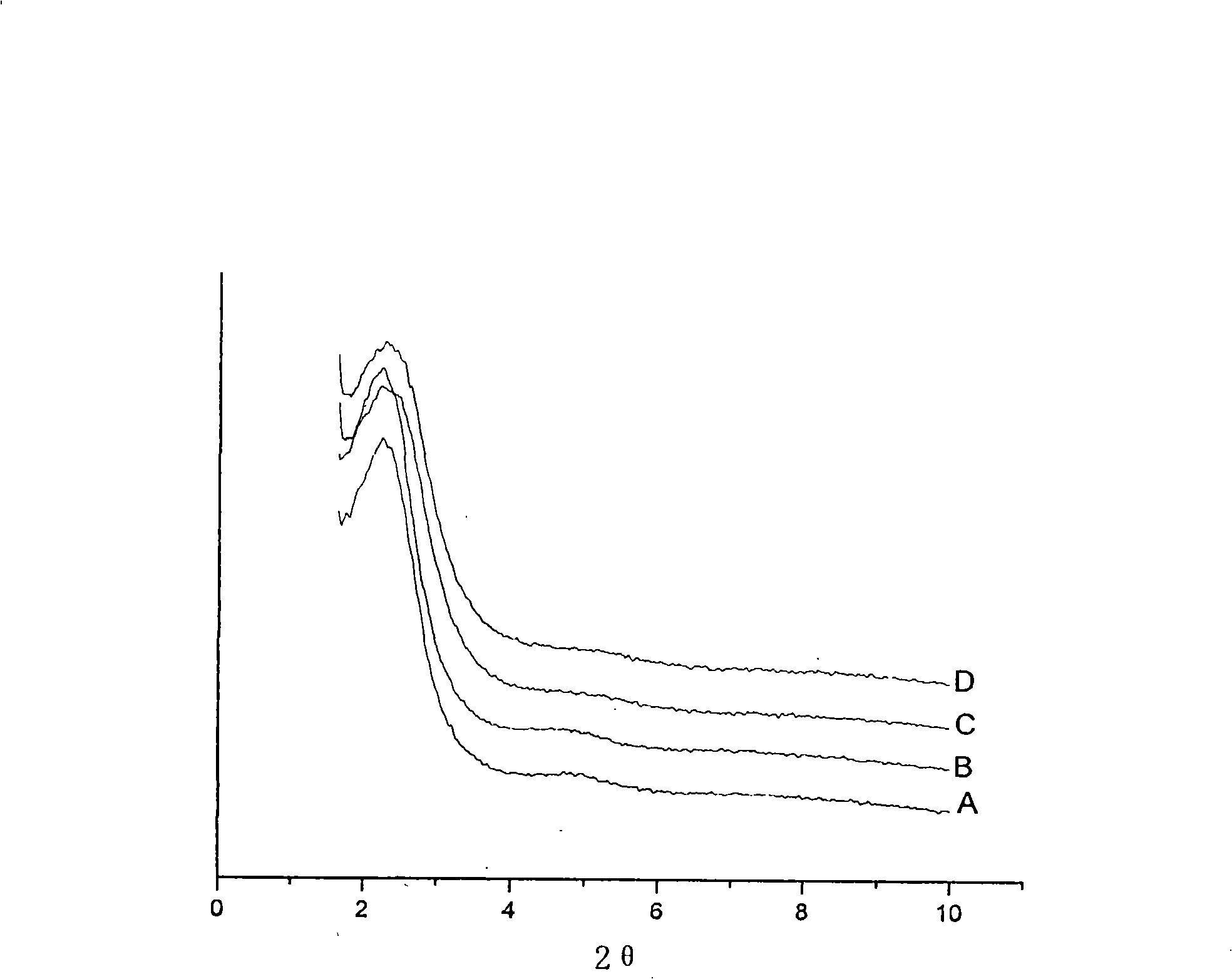

[0020] Weigh Cu(NO 3 ) 2 ·3H 2 O 2g, Zn(NO 3 ) 2 ·6H 2 O 1g, Al(NO 3 ) 3 9H 2 O20g, miscible in 100ml deionized water; weigh 1g trimethylhexadecyl ammonium bromide and dissolve it in 100ml deionized water, then mix the two under vigorous stirring, and adjust the pH value to 8.5 with 1M NaOH aqueous solution , continue stirring for 60 minutes. Transfer the generated slurry material to a 300ml stainless steel synthesis kettle and heat up to 120°C to continue the reaction for 100h. After the reaction is completed, cool to room temperature, discharge the material and wash it with a centrifuge for several times. The filter cake is dried at room temperature, and then Calcined in a tube furnace at 550°C for 20 hours in an air atmosphere, a solid substance was obtained, and its specific surface area was measured by nitrogen adsorption method (BET) to be 520m 2 / g, XRD method measures that it has mesoporous structure, illustrates that prepared material is the highly stable mes...

Embodiment 2

[0022] Weigh Cu(NO 3 ) 2 ·3H 2 O 2g, Zn(NO 3 ) 2 ·6H 2 O 1g, polyaluminum chloride (containing Al 2 o 320%) 20g, miscible in 100ml deionized water; weigh 2g sodium dodecylsulfonate and dissolve it in 100ml deionized water, then mix the two under vigorous stirring, and adjust the pH value to 7.5 with 1M KOH aqueous solution , continue stirring for 60 minutes. The resulting slurry material was transferred to a 300ml stainless steel synthesis kettle and continued to react at 20°C for 100h. After the reaction, the material was unloaded and washed several times with a centrifuge. The filter cake was dried at room temperature and then placed in a tube furnace. Calcined at 550°C for 20h in an air atmosphere to obtain a solid substance whose specific surface area was measured by nitrogen adsorption method (BET) to be 505m 2 / g, XRD method measures that it has mesoporous structure, illustrates that the obtained solid substance is the high stability mesoporous material Cu-Zn-Al ...

Embodiment 3

[0024] Weigh Cu(NO 3 ) 2 ·3H 2 O 3g, Zn(NO 3 ) 2 ·6H 2 O 2g, polyaluminum chloride (containing Al 2 o 3 20%) 20g, miscible in 100ml deionized water; weigh 2g betaine and dissolve it in 100ml deionized water, then mix the two under vigorous stirring, adjust the pH value to 10.5 with 1M KOH aqueous solution, and continue stirring for 60 minutes . The generated slurry material was transferred to a 300ml stainless steel synthesis kettle and continued to react at 50°C for 200h. After the reaction was completed, the material was unloaded and washed several times with a centrifuge. The filter cake was dried at room temperature and then placed in a tube furnace. Calcined at 550°C for 20h in an air atmosphere to obtain a solid substance whose specific surface area was measured by nitrogen adsorption method (BET) to be 525m 2 / g, XRD method measures that it has mesoporous structure, illustrates that the obtained solid substance is the high stability mesoporous material Cu-Zn-Al ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com