Preparation method of graphene-coated silicon dioxide nanoparticles

A technology of graphene coating and silicon dioxide, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problem of incomplete coating, and achieve the effect of good hydrophobicity, simple process and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of graphene oxide: Graphene oxide was prepared by the modified Hummers method using commercially available graphite powder as raw material. NaNO 3 Add it into concentrated sulfuric acid, add graphite powder and potassium permanganate after complete dissolution, and obtain a bright yellow system after further reaction, obtain graphite oxide after filtering and drying; then pass through a tube furnace to prepare graphene oxide powder through thermal expansion.

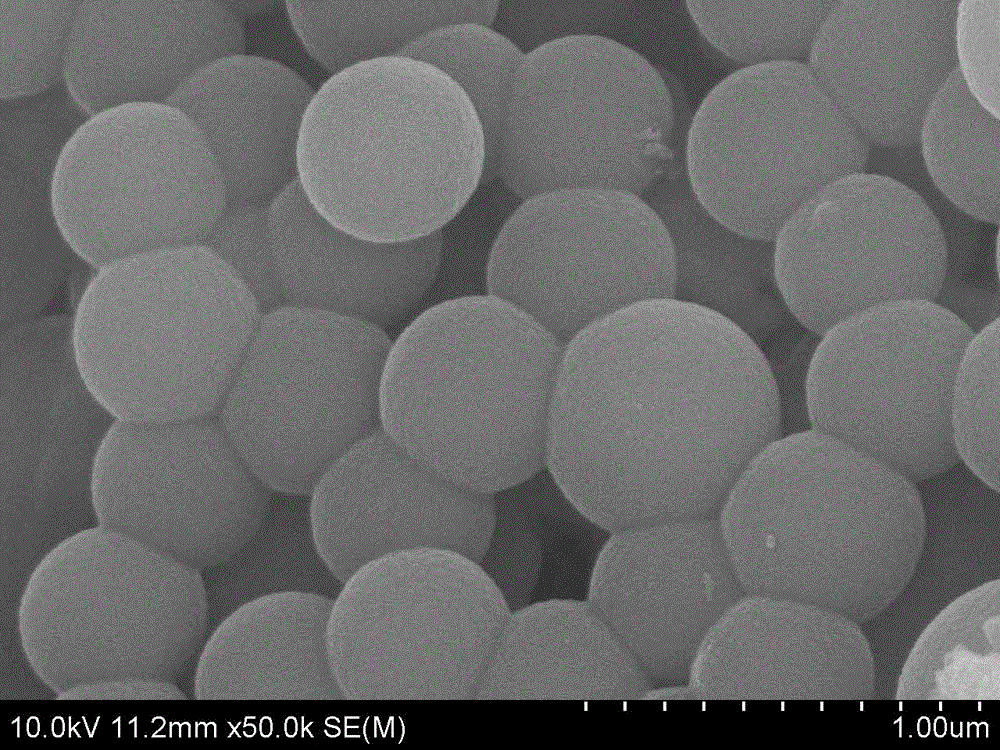

[0028] (2) SiO 2 Preparation of nanospheres: Add 0.5 g of cetyltrimethylammonium bromide to 60 ml of absolute ethanol, stir for 30 min, then slowly add 3.0 ml of tetraethyl orthosilicate, 1.0 ml of ammonia water and 10 ml of Ionized water, stirred for 4 hours, washed three times with ethanol and deionized water, and placed at 70 o C drying oven, and then placed in the muffle furnace 550 o C sintered for 3 hours to obtain SiO 2 microsphere powder.

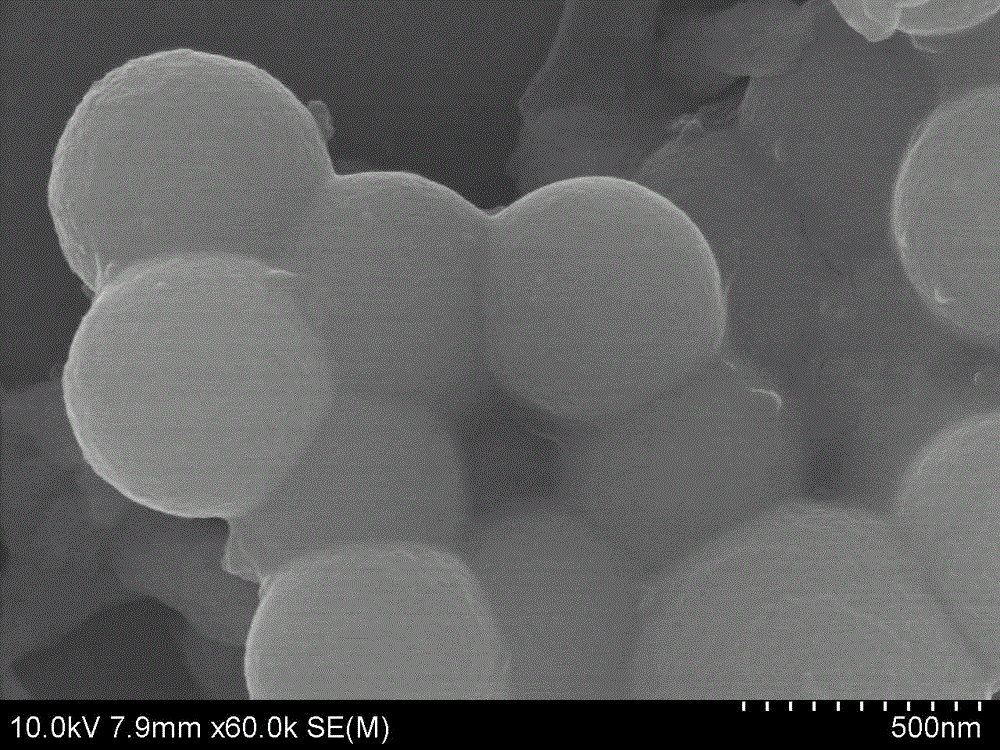

[0029] (3) Graphene@SiO 2 Preparation of com...

Embodiment 2

[0031] (1) The preparation method of graphene oxide is the same as step (1) in Example 1;

[0032] (2) SiO 2 The preparation method of nano-microspheres is the same as step (2) in Example 1;

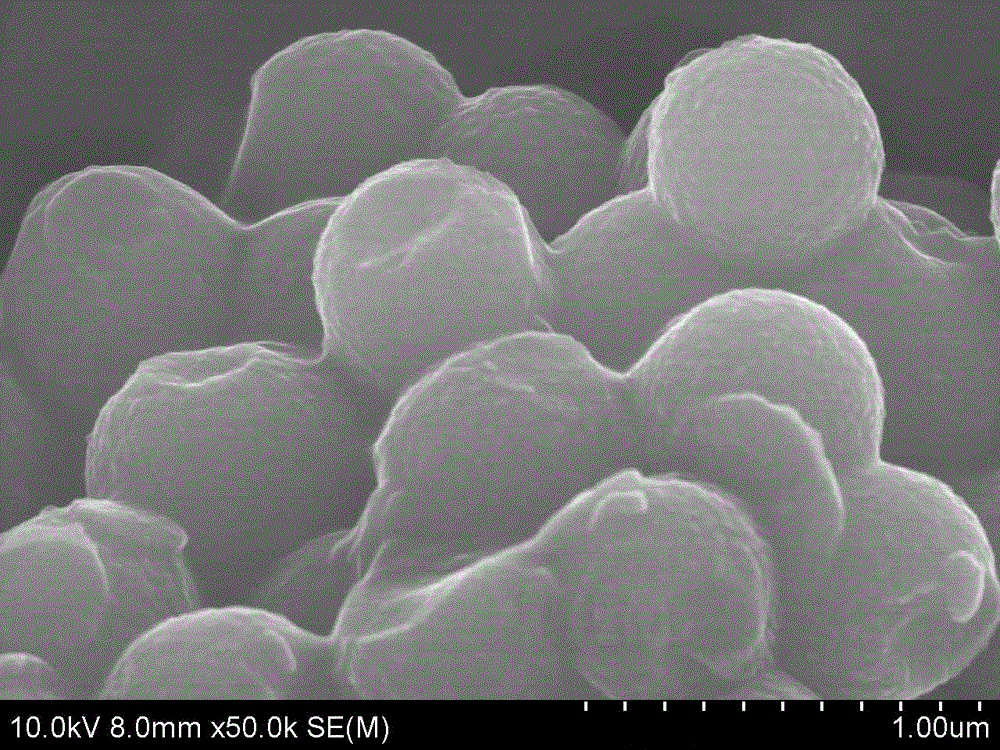

[0033] (3) Graphene@SiO 2 Preparation of composite materials: the implementation method is the same as step (3) in Example 1, the difference from Example 1 is that the added silane coupling agent is different, and the silane coupling agent used in this example is 3-aminopropylmethyl Dimethoxysilane (KH-662), still obtain graphene-coated complete SiO 2 composite material. image 3 SiO coated with graphene 2 SEM image of the composite, graphene coated on SiO 2 The surface of the nano-microspheres, the degree of coating is still good.

Embodiment 3

[0035] (1) The preparation method of graphene oxide is the same as step (1) in Example 1;

[0036] (2) SiO 2 The preparation method of nano-microspheres is the same as step (2) in Example 1;

[0037] (3) Graphene@SiO 2 Preparation of composite material: the implementation method is the same as step (3) in Example 1, the difference from Example 1 is that the pH value when graphene oxide coating is different, this example uses the pH value control when graphene oxide coating is 3, and graphene-coated complete SiO can still be obtained 2 composite material. This shows that under acidic conditions, graphene can still be coated on SiO 2 The surface of the nano-microsphere has a good coating degree.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com