Magnetic mesoporous titanium dioxide core-shell type compound microsphere as well as preparation method and application thereof

A technology of mesoporous titanium dioxide and composite microspheres is applied in the preparation of microspheres, microcapsule preparations, magnetic properties of inorganic materials, etc. It can solve the problems of complicated separation and low purity, and achieve uniform particle size distribution, good effect and regular structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

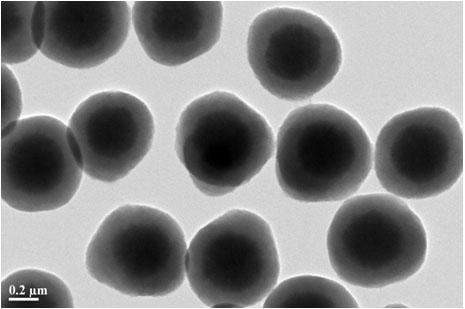

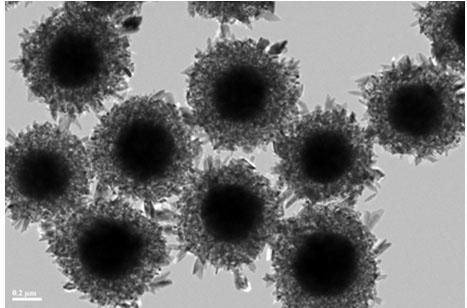

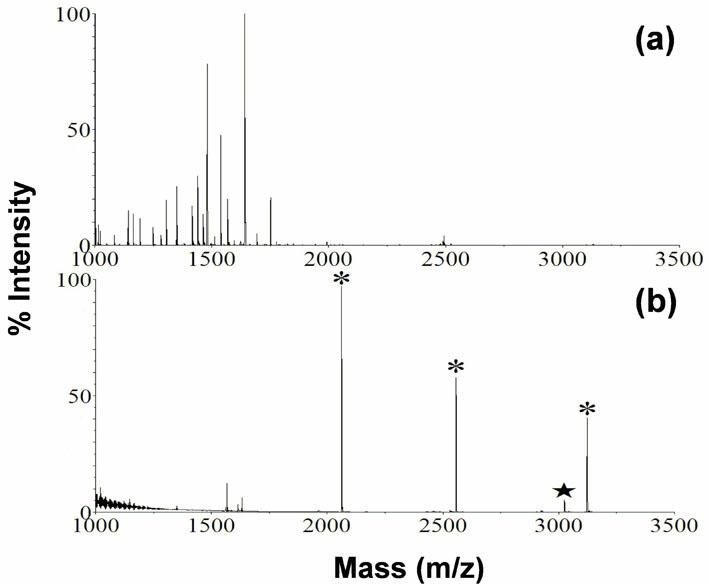

[0022] Example 1: The magnetic core is about 300nm, the thickness of the titanium dioxide shell is about 50nm, and the core-shell Fe with a pore diameter of about 20nm 3 o 4 mO 2 Preparation of Microspheres and Their Application to the Selective Isolation of Phosphopeptides at Very Low Levels in Biological Samples

[0023] 1. Preparation of citric acid-stabilized magnetic clusters

[0024] 1.2g ferric chloride hexahydrate (FeCl 3 ·6H 2 O), 2.4g ammonium acetate (NH 4 Ac), after dissolving 0.3g citric acid in 70mL ethylene glycol, put it into a 150mL three-neck flask, then raise the temperature to 140°C, keep it warm for 1 hour, then transfer the liquid in the flask to a 100mL Teflon-lined In a high-pressure reaction kettle, put the reaction kettle into an oven at 200°C for 24 hours, take it out, and cool it to room temperature with tap water. The product was separated by magnetic separation, washed with absolute ethanol to remove unreacted reactants, and finally the prod...

Embodiment 2

[0031] Example 2: a core-shell Fe with a magnetic core of about 150 nm, a titanium dioxide shell thickness of about 50 nm, and a pore diameter of about 20 nm 3 o 4 mO 2 Preparation of Microspheres and Their Application to the Selective Isolation of Phosphopeptides at Very Low Levels in Biological Samples

[0032] 1. The preparation of citric acid-stabilized magnetic clusters is the same as described in Example 1-1. The difference is that the reaction temperature in the flask was changed from 140°C to 20°C.

[0033] 2. Core-shell Fe 3 o 4 TiO 2 The preparation is the same as described in Example 1-2. The difference is that the amount of tetrabutyl titanate is changed from 1 mL to 0.6 mL.

[0034] 3. Core-shell Fe 3 o 4 mO 2 The preparation is the same as described in Examples 1-3.

[0035] 4. The test method for selectively separating extremely low-level phosphopeptides in biological samples is the same as that described in Examples 1-4. In this example, the selecti...

Embodiment 3

[0036] Example 3: a core-shell Fe with a magnetic core of about 300nm, a titanium dioxide shell thickness of about 100nm, and a pore diameter of about 20nm 3 o 4 mO 2 Preparation of Microspheres and Their Application to the Selective Isolation of Phosphopeptides at Very Low Levels in Biological Samples

[0037] 1. The preparation of citric acid-stabilized magnetic clusters is the same as described in Example 1-1.

[0038] 2. Core-shell Fe 3 o 4 TiO 2 The preparation is the same as described in Example 1-2. The difference is that the amount of tetrabutyl titanate is changed from 1 mL to 2 mL.

[0039] 3. Core-shell Fe 3 o 4 mO 2 The preparation is the same as described in Examples 1-3.

[0040] 4. The test method for selectively separating extremely low-level phosphopeptides in biological samples is the same as that described in Examples 1-4. In this example, the selectivity of the microspheres for phosphopeptides is the same as Example 1, the magnetic separation spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com