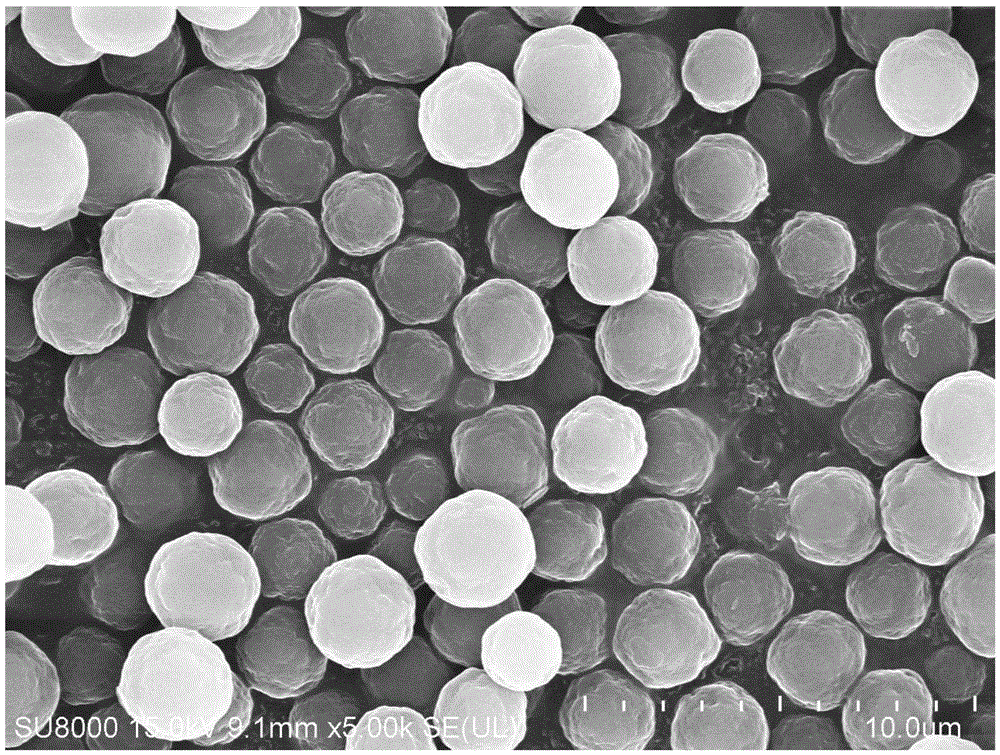

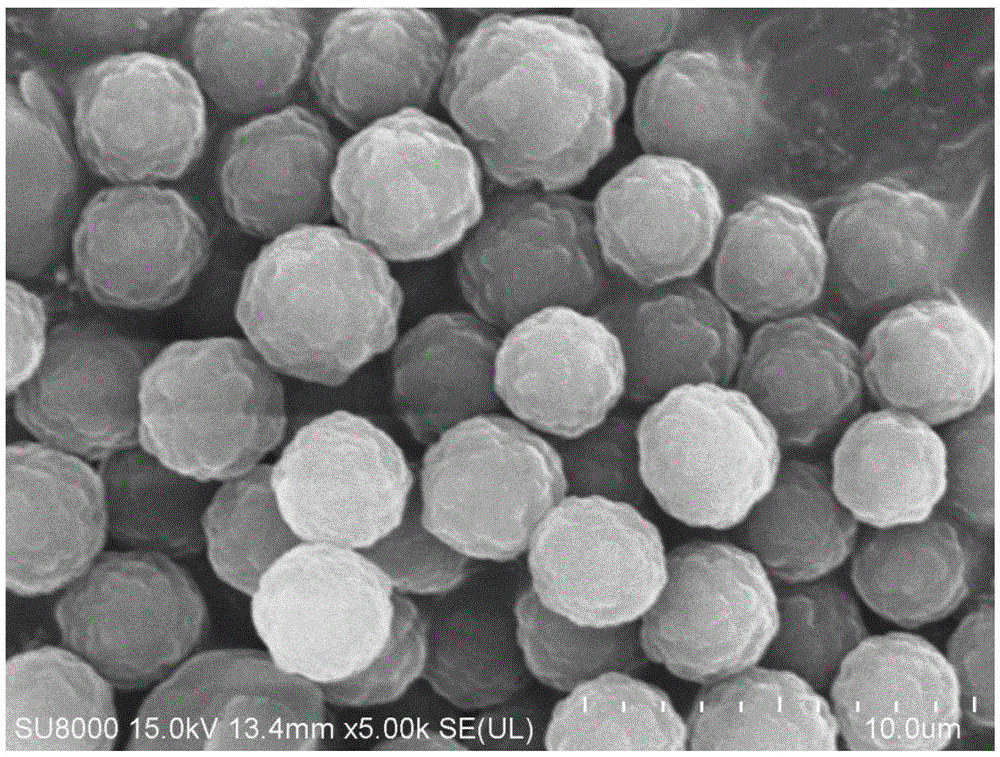

Method for preparing monodisperse carbon microspheres by using cane sugar as carbon source

A monodisperse, carbon microsphere technology, applied in the field of new carbon material preparation, can solve the problems of monodisperse micron-scale carbon spheres, which have not been reported in literature, and the particle size distribution range of ball and ball adhesion, etc., to achieve regular structure and surface. Coarse, uniform particle size distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Preparation of monodisperse carbon microspheres with a particle size of 5.5 μm

[0033] Add 17g of sucrose into a beaker filled with 15-50ml of deionized water. After it is fully dissolved, add 2-30mg of sodium polyacrylate, and ultrasonically dissolve it into a transparent solution. Slowly pour the solution into a hydrothermal kettle lined with polytetrafluoroethylene, tighten the hydrothermal kettle and put it into an oven that has reached 240°C. After reacting for 12h-24h, take out the hydrothermal kettle and allow it to cool down to room temperature naturally. The obtained product is a dark brown precipitate. Wash the obtained product several times with deionized water and ethanol successively, and then move it into an oven at 50°C-80°C for drying The product is monodisperse microspheres with a particle size of 5 μm.

Embodiment 2

[0034] Example 2: Preparation of monodisperse carbon microspheres with a particle size of 4 μm

[0035] The steps are as shown in Embodiment 1, except that the amount of sucrose is 17g, and the oven temperature is 200°C.

Embodiment 3

[0036] Example 3: Preparation of monodisperse carbon microspheres with a particle size of 1.5 μm

[0037] The steps are as shown in Embodiment 1, the difference is that the amount of sucrose is 8g, and the reaction time is 8h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com