High-strength hot-rolled steel plate

一种热轧钢板、高强度的技术,应用在金属轧制、热处理炉、热处理设备等方向,能够解决焊接施工操作性差等问题,达到疲劳特性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

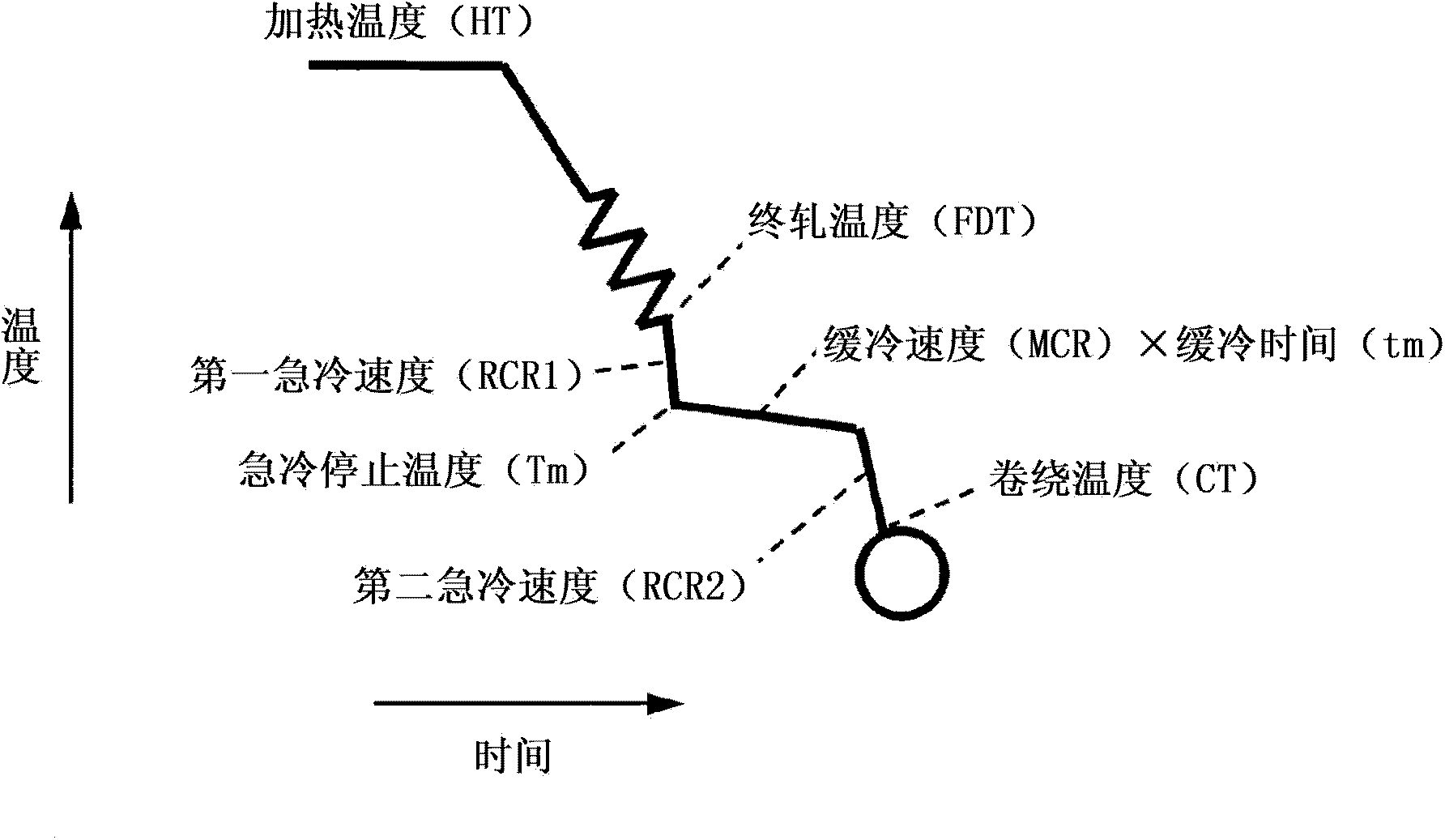

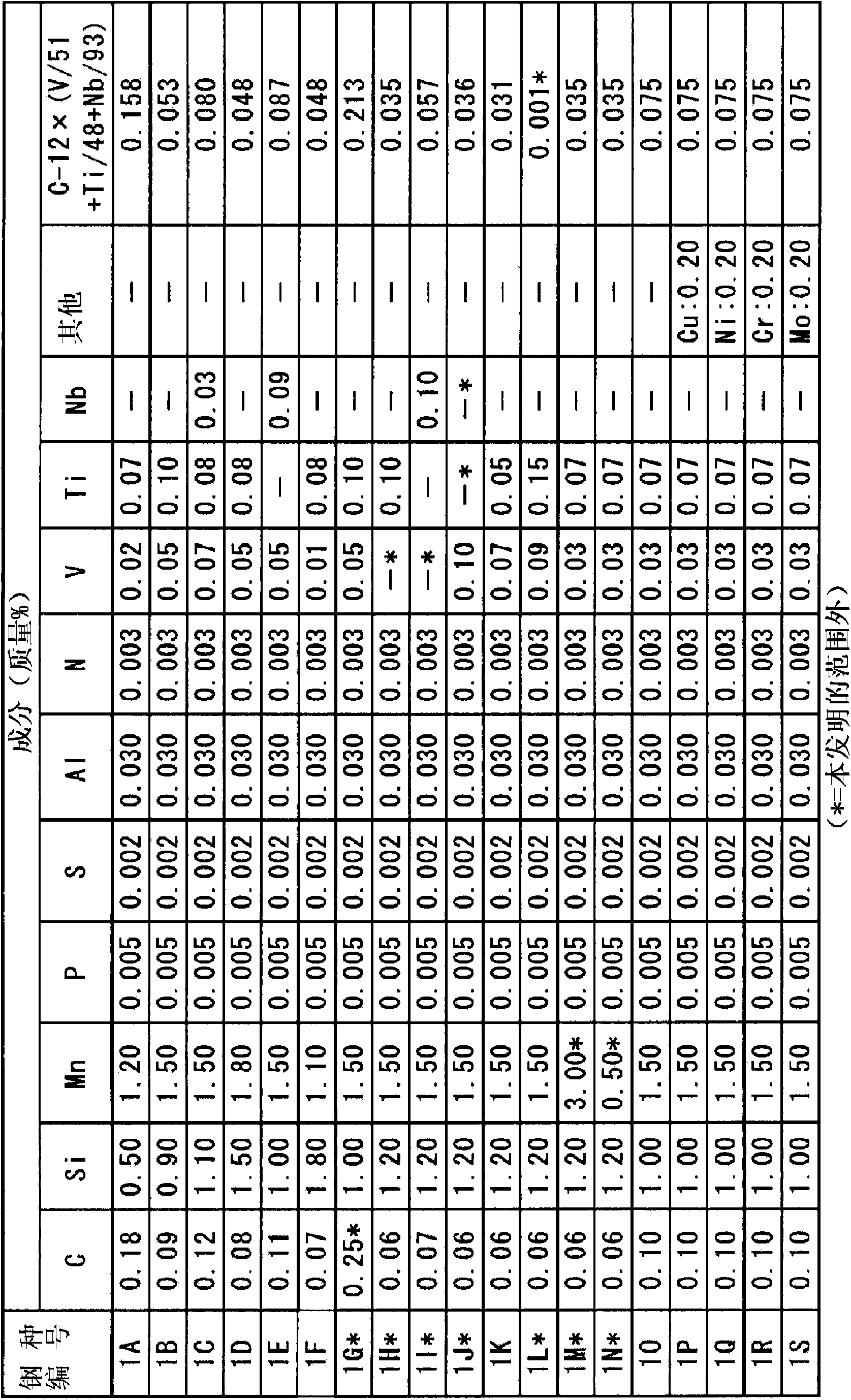

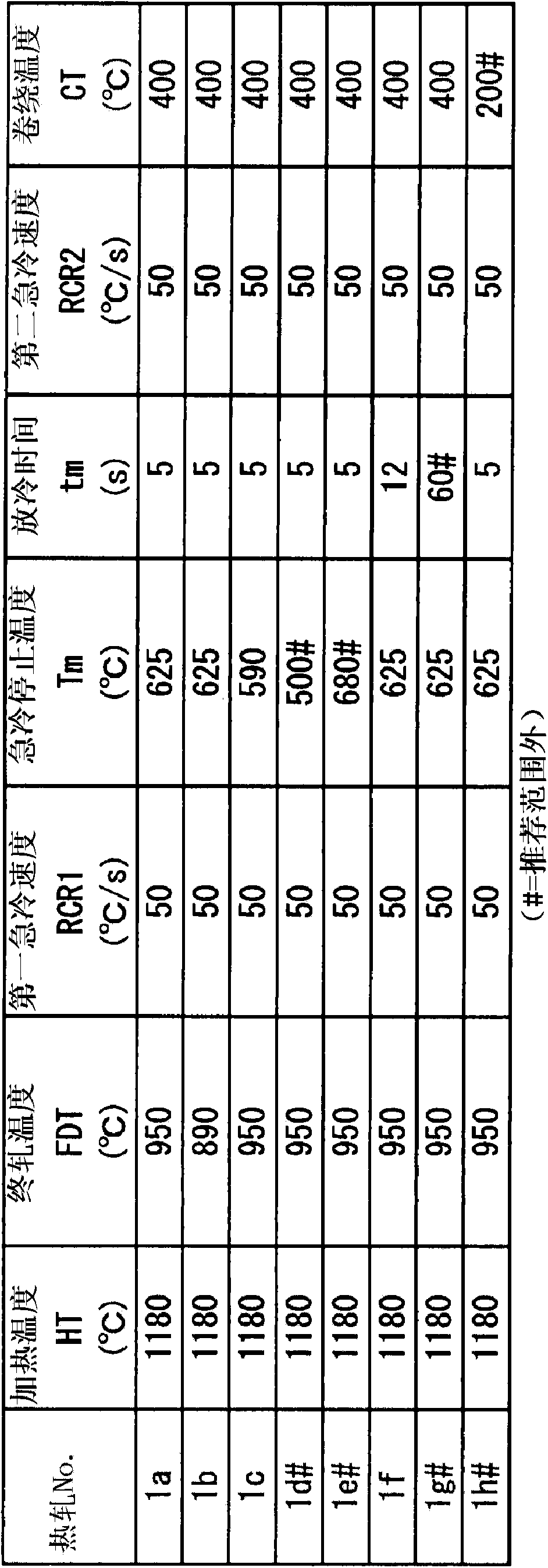

[0110] A test steel having the composition shown in Table 1 below was vacuum-melted to obtain a test material having a plate thickness of 30 mm. by figure 1 With the program shown and the conditions shown in Table 2 below, this test material was hot-rolled to produce a hot-rolled steel sheet. More specifically, after the heating temperature HT is maintained for 30 minutes, the finish rolling is performed at the finish rolling temperature FDT, and the final plate thickness is 3 mm. After finishing rolling, it is cooled to the rapid cooling stop temperature Tm at the first rapid cooling rate RCR1, and only allowed to cool for the cooling time (slow cooling time) tm. In addition, the cooling rate (slow cooling rate) MCR during standing cooling is 10° C. / s or less. Thereafter, it is cooled to the coiling temperature CT at the second rapid cooling rate RCR2, kept for 30 minutes, and then furnace cooled.

[0111] For the hot-rolled steel sheet (corresponding to the base material)...

Embodiment 2

[0129] A test steel having the composition of each component shown in Table 4 below was vacuum melted to obtain a test material having a plate thickness of 30 mm. by figure 1 The program shown and the conditions shown in the following Table 5 were hot-rolled with respect to this test material, and the hot-rolled steel plate was produced. More specifically, after the heating temperature HT is maintained for 30 minutes, the finish rolling is performed at the finish rolling temperature FDT, and the final plate thickness is 3 mm. After finishing rolling, it is cooled to the rapid cooling stop temperature Tm at the first rapid cooling rate RCR1, and only allowed to cool for the cooling time (slow cooling time) tm. In addition, the cooling rate (slow cooling rate) MCR during standing cooling is 10° C. / s or less. Afterwards, cool to the coiling temperature CT at the second rapid cooling rate RCR2, keep it for 30 minutes, and then carry out furnace cooling.

[0130] For the hot-rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com