High-strength steel sheet and production method for same, and production method for high-strength galvanized steel sheet

A high-strength steel sheet and a manufacturing method technology, applied in manufacturing tools, hot-dip plating processes, furnaces, etc., can solve problems such as increased deviation, poor shape, and reduced mass production efficiency, and achieve improved fuel efficiency, excellent fatigue characteristics, Use high-value effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

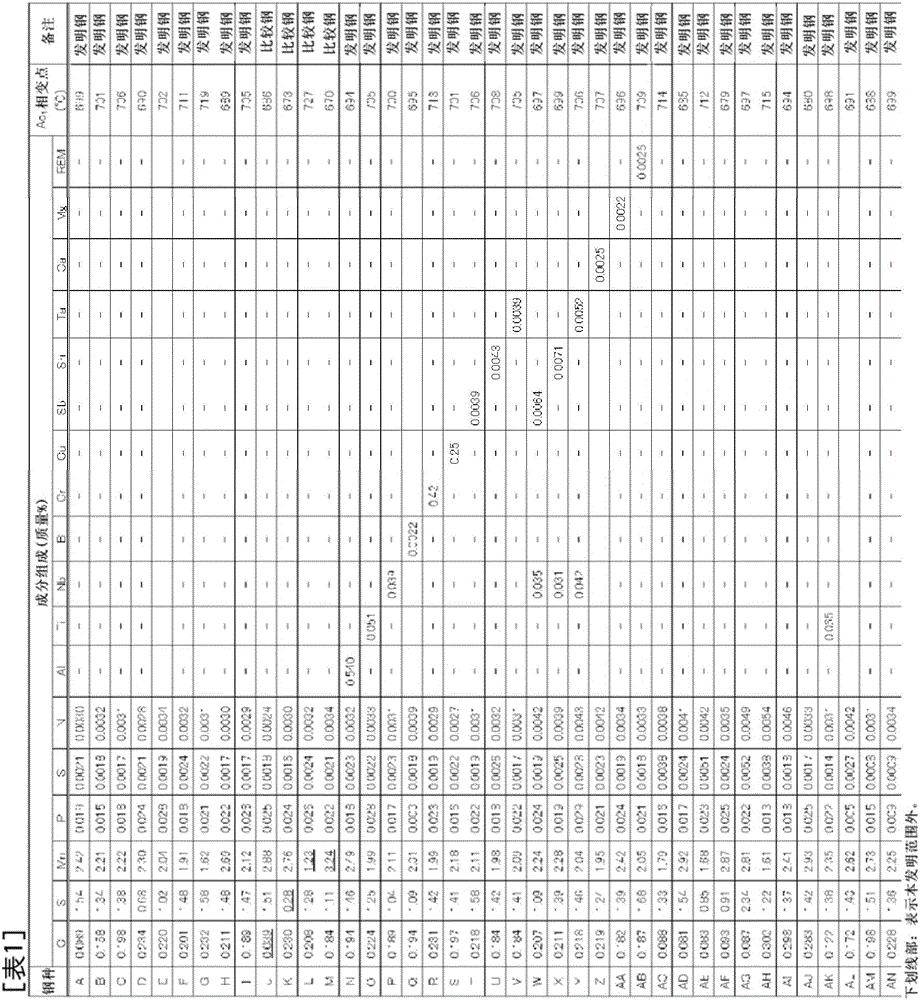

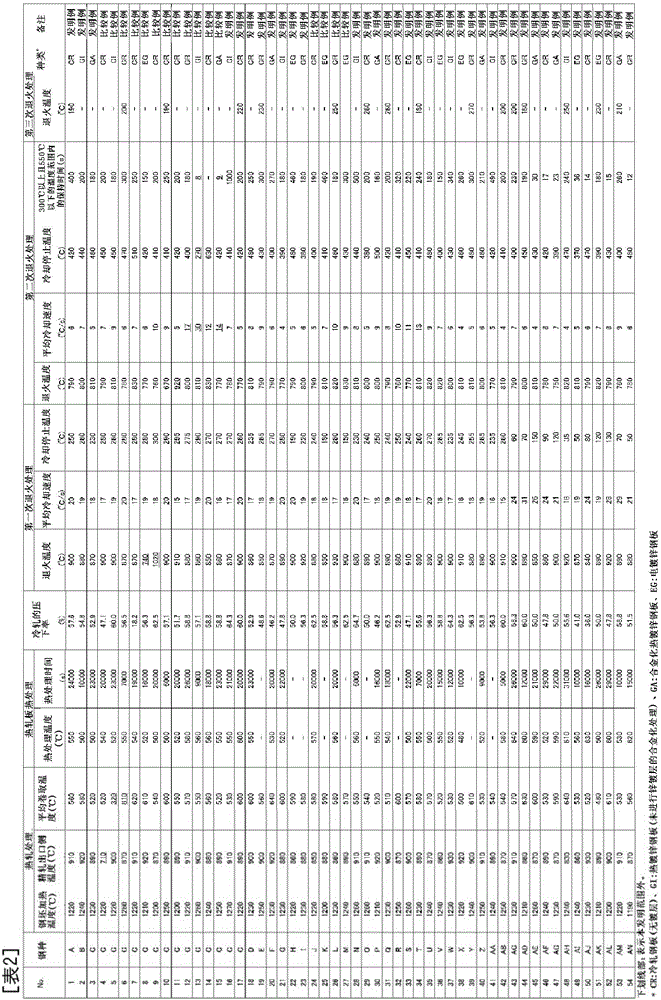

[0176] Steel having the composition shown in Table 1, with the balance consisting of Fe and unavoidable impurities was melted in a converter and cast into billets by continuous casting. The obtained slabs were heated under the conditions shown in Table 2, and hot-rolled to obtain steel sheets. Then, pickling treatment was performed on the steel sheet. Then, for Nos.1 to 18, 20, 21, 24, 26, 28, 30, 31, 33 to 38, 40, 42 to 54 shown in Table 2, implement a hot-rolled sheet heat treatment, and further, for the No. 28, 30, 31, 33-38, 40, 42, carry out pickling treatment after heat treatment of hot rolled sheet.

[0177] Next, after cold-rolling the steel sheet under the conditions shown in Table 2, the steel sheet was subjected to two or three annealing treatments under the conditions shown in Table 2 to obtain a high-strength cold-rolled steel sheet (CR).

[0178] Furthermore, a part of the high-strength cold-rolled steel sheet (CR) is galvanized to obtain a galvanized steel she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com