Iron-based memory alloy laser cladding composite coating powder

A laser cladding and memory alloy technology, which is applied in the field of laser cladding surface modification, can solve the problems of limited application range, low hardness and wear resistance of memory alloy coating, reduce the content of microporous structure and improve the coating quality. Hardness and wear resistance, the effect of improving the corrosion resistance of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

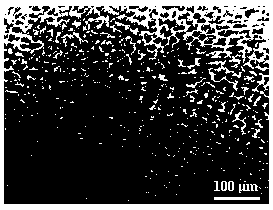

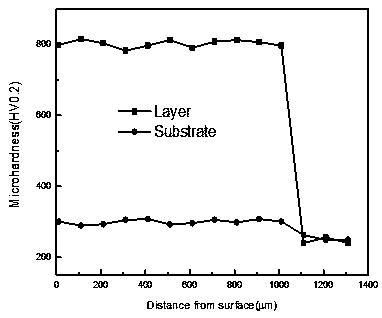

Image

Examples

Embodiment 1

[0026] Embodiment 1 of the present invention: a kind of iron-based memory alloy laser cladding composite coating powder, is made with the raw material of following weight composition ratio: pure iron powder 46.9kg, manganese powder 28kg, silicon powder 8kg, chromium powder 3.5kg , nickel powder 2.5kg, niobium powder 0.5kg, tungsten carbide powder 10kg, yttrium oxide powder 0.6kg.

[0027] The preparation method of the iron-based memory alloy laser cladding composite coating powder is as follows: use an electronic balance with an accuracy of 0.1mg, weigh and mix various raw material powders according to the above weight component ratio, and put the mixed powder into the stainless steel ball milling tank of the ball mill In the process, stainless steel balls are used as the ball milling medium, and absolute ethanol is used as the milling medium for ball milling, and the powder after ball milling is vacuum-dried to obtain the laser cladding coating powder.

[0028] During the bal...

Embodiment 2

[0030] Embodiment 2 of the present invention: a kind of iron-based memory alloy laser cladding composite coating powder, is made with the raw material of following weight composition ratio: pure iron powder 48.4kg, manganese powder 24.5kg, silicon powder 7kg, chromium powder 5kg , Nickel powder 6kg, niobium powder 0.9kg, tungsten carbide powder 7kg, yttrium oxide powder 1.2kg.

[0031] The preparation method of the iron-based memory alloy laser cladding composite coating powder is as follows: use an electronic balance with an accuracy of 0.1mg, weigh and mix various raw material powders according to the above weight component ratio, and put the mixed powder into the stainless steel ball milling tank of the ball mill In the process, stainless steel balls are used as the ball milling medium, and absolute ethanol is used as the milling medium for ball milling, and the powder after ball milling is vacuum-dried to obtain the laser cladding coating powder.

[0032] During the ball m...

Embodiment 3

[0034] Embodiment 3 of the present invention: a kind of iron-based memory alloy laser cladding composite coating powder, is made with the raw material of following weight composition ratio: pure iron powder 49.2kg, manganese powder 23kg, silicon powder 7.5kg, chromium powder 3kg , Nickel powder 1.6kg, niobium powder 1.3kg, tungsten carbide powder 13kg, yttrium oxide powder 2.4kg.

[0035] The preparation method of the iron-based memory alloy laser cladding composite coating powder is as follows: use an electronic balance with an accuracy of 0.1mg, weigh and mix various raw material powders according to the above weight component ratio, and put the mixed powder into the stainless steel ball milling tank of the ball mill In the process, stainless steel balls are used as the ball milling medium, and absolute ethanol is used as the milling medium for ball milling, and the powder after ball milling is vacuum-dried to obtain the laser cladding coating powder.

[0036] During the bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com