Hot rolled steel sheet having excellent punching workability and fatigue properties, hot dip galvanized steel sheet, and method for producing the same

A technology for hot-dip galvanized steel sheet and fatigue characteristics, applied in the field of hot-rolled steel sheets, can solve the problems of deterioration of fatigue characteristics of blanking parts, unoptimized hot-rolling conditions, large unevenness, etc., so as to suppress the deviation of structure and material, reduce the The effect of less plate thickness and end surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

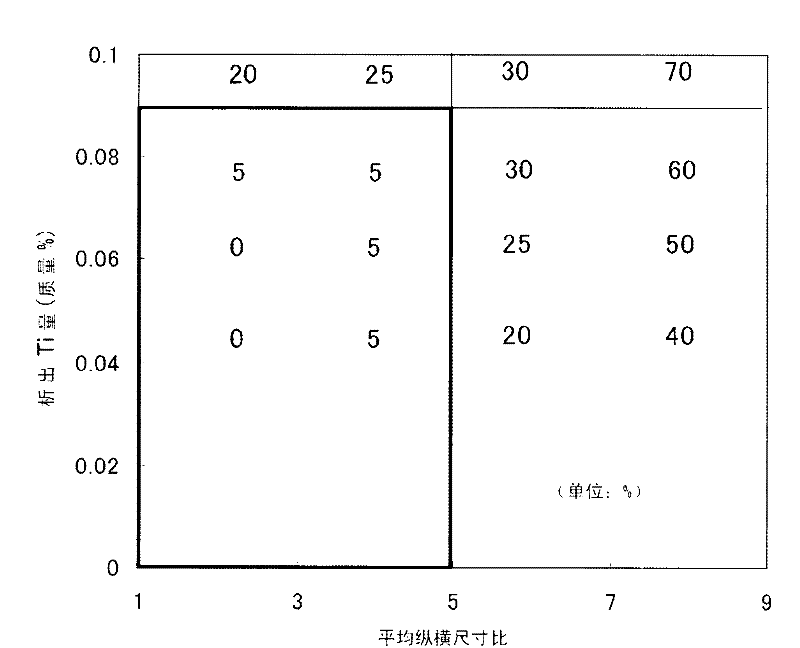

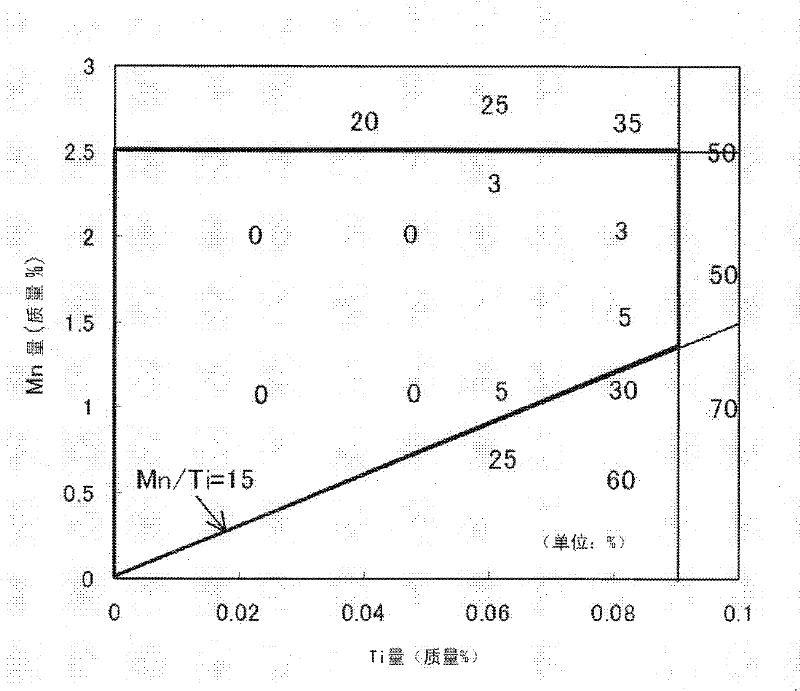

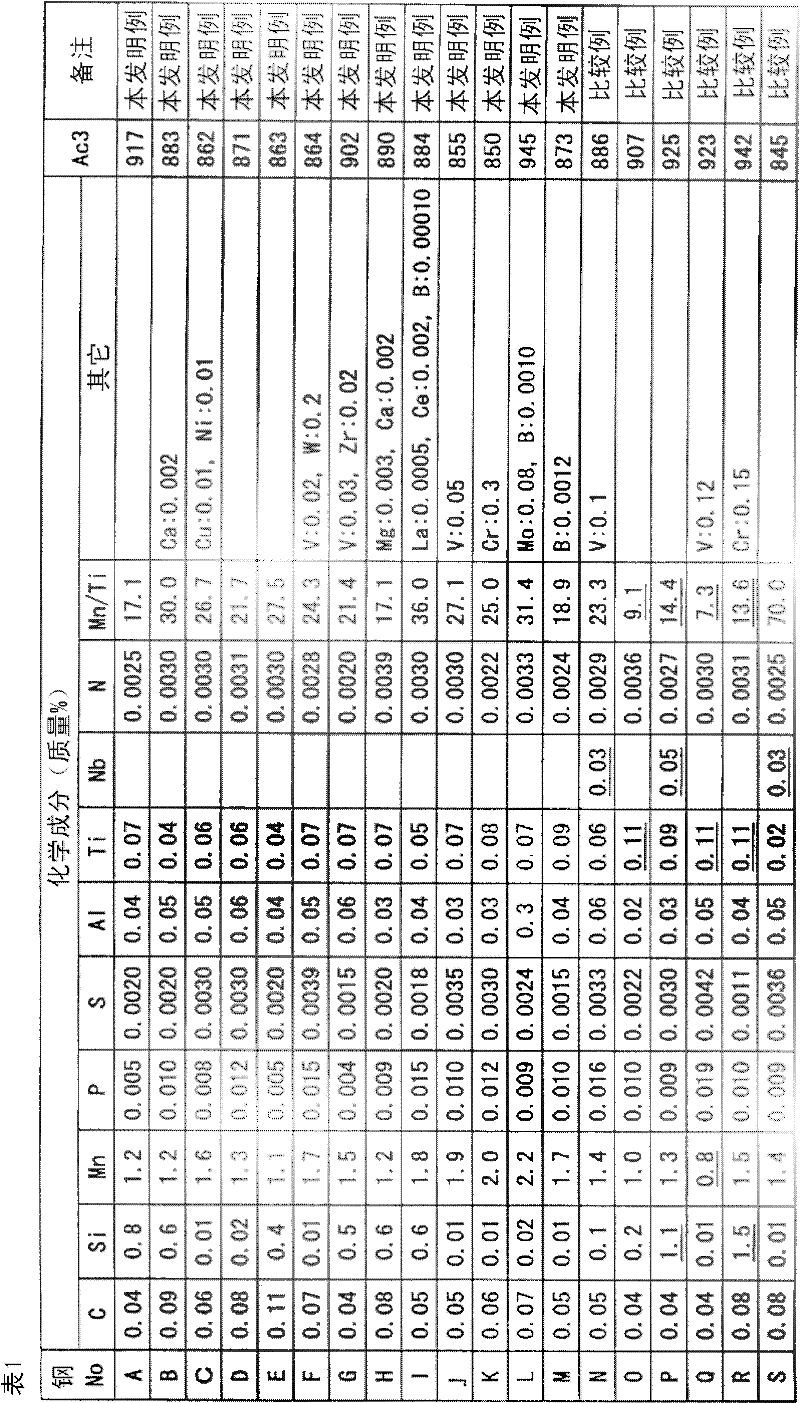

[0123] Hereinafter, the present invention will be further described by way of examples.

[0124] Steels A to R having the chemical components shown in Table 1 were produced by the following method. First, after casting a slab, the slab was reheated under the conditions shown in Tables 2 to 4, and rough rolled to form a rough bar. Next, the rough bar is subjected to finish rolling, formed into a rolled material having a thickness of 5 to 10 mm, cooled, and then coiled as a hot-rolled steel sheet.

[0125] In addition, steels F-1 and G-2 were produced by reheating hot-rolled steel sheets.

[0126]

[0127]

[0128]

[0129]

[0130] The chemical composition in the table is represented by mass %. In addition, in Table 1, Ac3 is the value computed by the following formula.

[0131] Ac3=910-203√(%C)+45×%Si-30×%Mn-11×%Cr+700×%P+400×%Al+400×%Ti

[0132] In the formula, %C, %Si, %Mn, %Cr, %P, %Al, and %Ti represent the contents of C, Si, Mn, Cr, P, Al, and Ti, respecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com