Grain-refined gear steel and production process thereof

A technology of grain refinement and production process, applied in the field of metallurgy, can solve the problems of affecting the fatigue life of gears, affecting the machining accuracy, serious harm, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] Embodiment 1 of the present invention, reference example 220CrMnTi

[0053] 1) chemical composition is as follows table 1 (wt%):

[0054] project C Cr mn Si P S Alt B Ni Mo Cu N Ti Example 1 20CrMnBAlN 0.19 0.85 0.85 0.26 0.015 0.025 0.0500 0-0018 0.01 0.005 0.04 0.0120 Reference example 2 20CrMnTi 0.19 1.06 0.95 0.24 0.012 0.007 0.0350 0.01 0.005 0.04 0.056

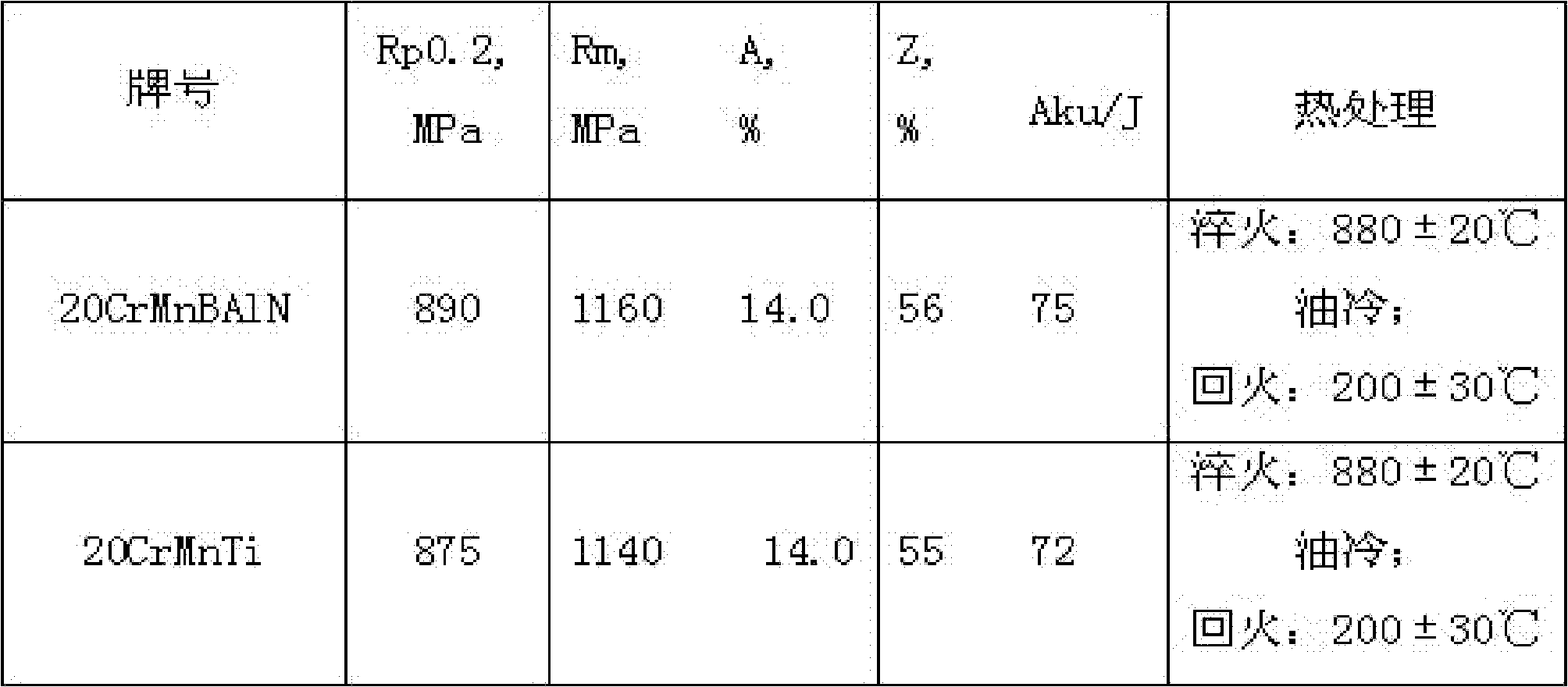

[0055] 2) The mechanical properties are compared in the following table 2:

[0056] Table 2

[0057]

[0058] 4) Grain degree: 20CrMnAlS grade 8, 20CrMnTi grade 7.

[0059] 5) Microstructure: The hot-rolled state is F+P microstructure.

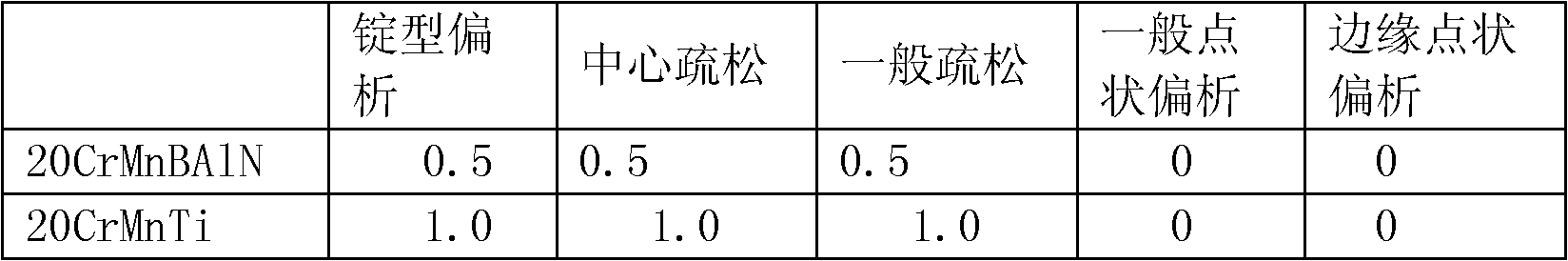

[0060] 6) Low magnification as shown in Table 3:

[0061] table 3

[0062]

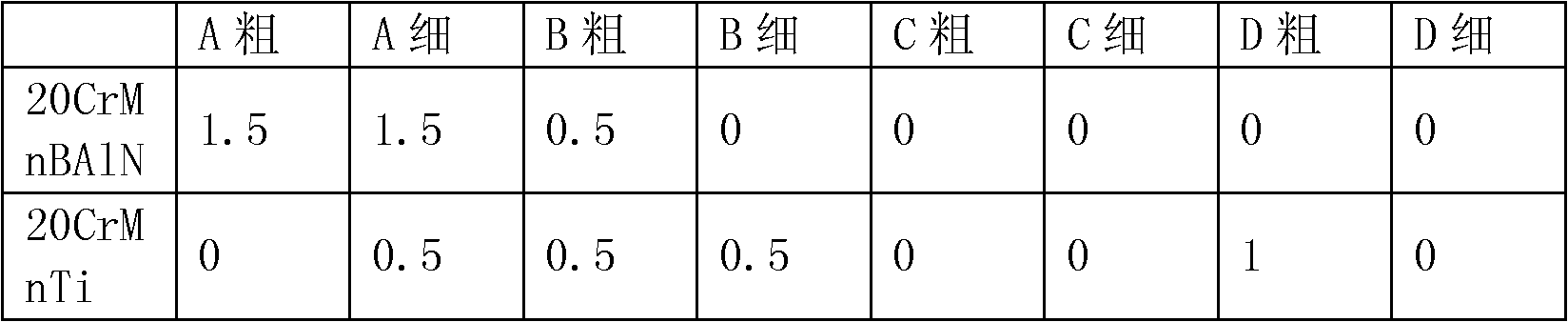

[0063] 7). Inclusions are as shown in Table 4:

[0064] Table 4

[0065]

[0066] 8) Comparison of terminal hardenability (20CrMnAlS and 20CrMnTi) is shown in Table 5:

[0067] table 5

[0068]

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com