High-strength steel sheet excellent in stretch flangeability and fatigue property

A technology of high-strength steel plate and fatigue characteristics, applied in the field of high-strength hot-rolled steel plate, which can solve the problems of fracture, the inability of the boundary of two phases to adapt to deformation, and poor stretch flangeability.

Active Publication Date: 2009-07-22

NIPPON STEEL CORP

View PDF2 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] It is known that this DP steel sheet is excellent in the balance of strength and ductility and fatigue properties, but the tensile flangeability evaluated by the hole expansion test is still not good.

One of the reasons may be that the DP steel plate is a complex of soft ferrite phase and hard martensite phase, so the boundary between the two phases cannot adapt to deformation during hole expansion and is likely to become the starting point of fracture

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

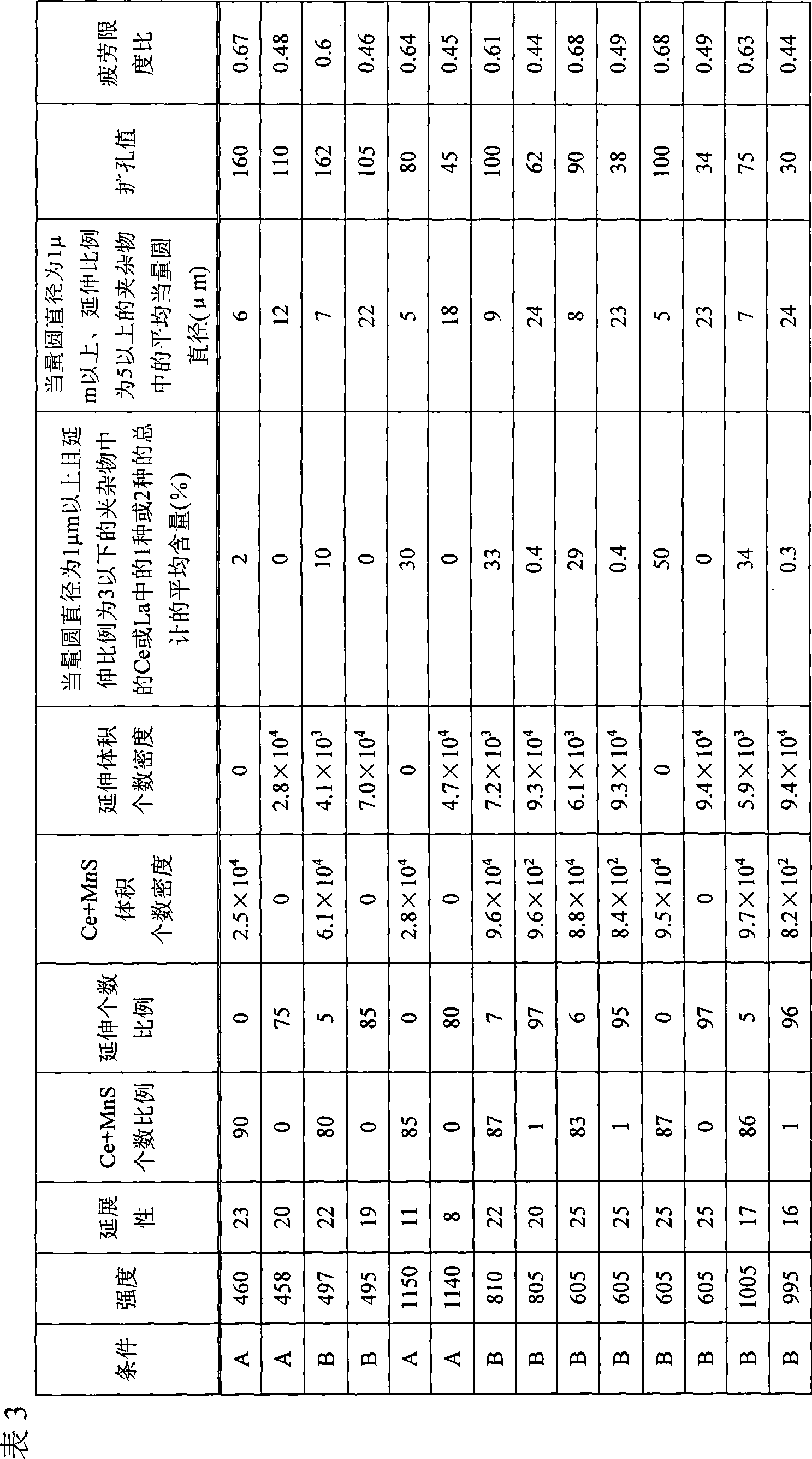

[0108] Next, examples of the present invention will be described together with comparative examples.

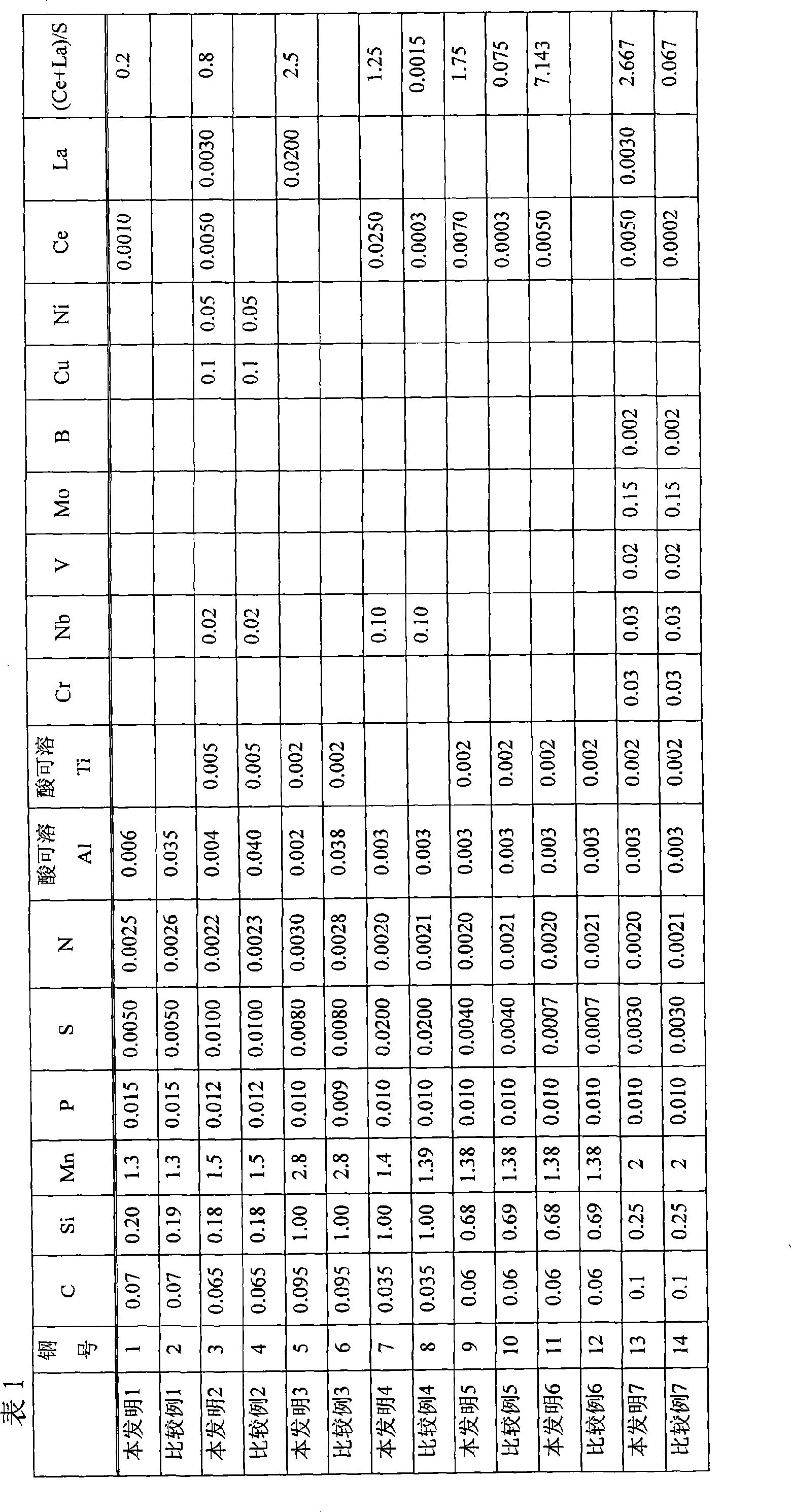

[0109] The slabs with the chemical compositions shown in Table 1 were hot-rolled under the conditions shown in Table 2 to obtain hot-rolled sheets with a thickness of 3.2 mm.

[0110]

[0111] Table 2

[0112]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

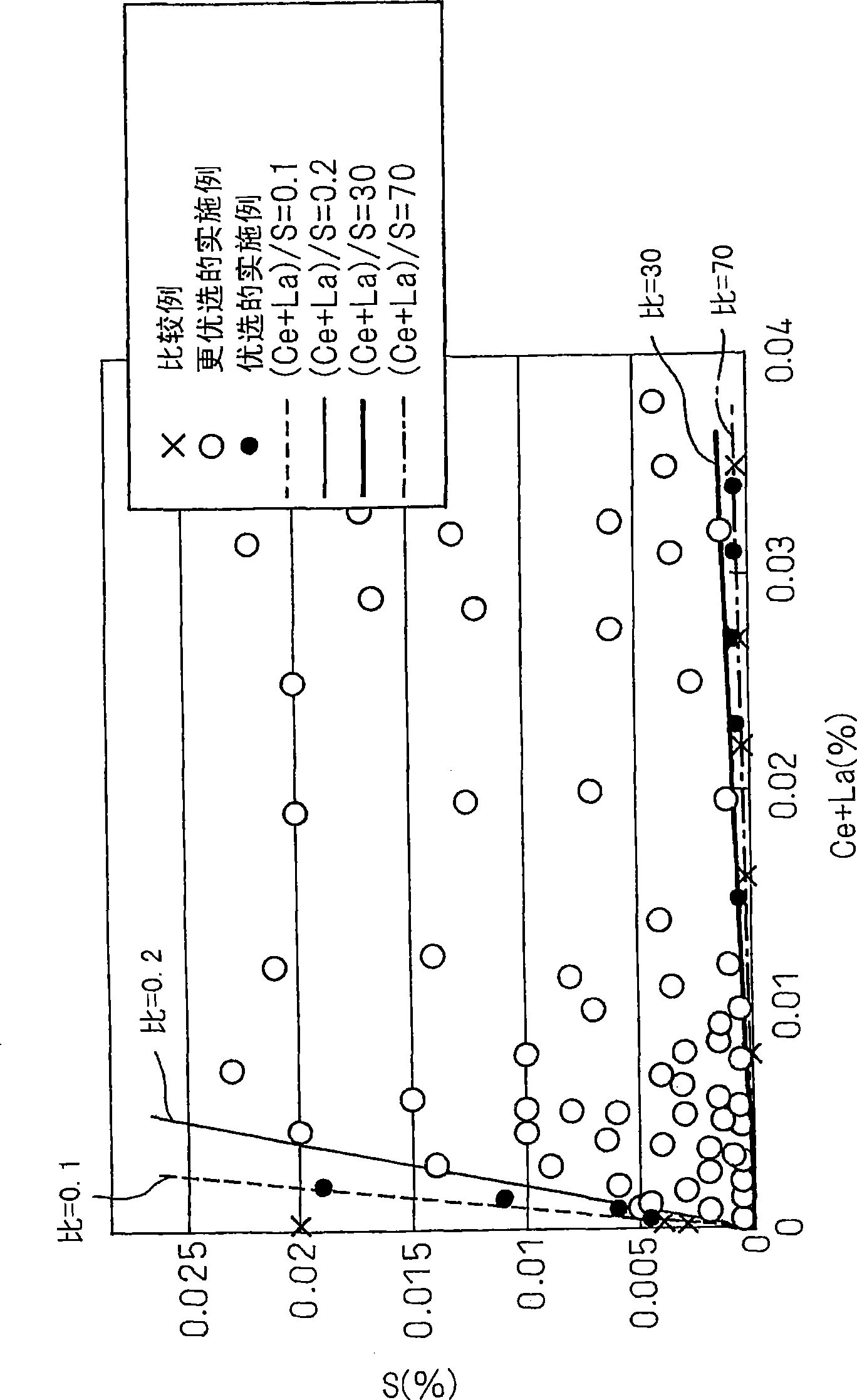

The invention provides a high-strength hot-rolled steel sheet excellent in stretch flangeability and fatigue properties. The steel sheet contains 0.03-0.20% C, 0.08-1.5% Si, 1.0-3.0% Mn, up to 0.05% P, at least 0.0005% S, 0.0005-0.01% N, up to 0.01% acid-soluble Al, less than 0.008% acid-soluble Ti, and 0.0005-0.04% at least either of Ce and La, the remainder being iron and unavoidable impurities. The steel sheet contains stretched inclusions which have a diameter, in terms of equivalent-circle diameter, of 1 mum or larger and in which the ratio of the major-axis length to the minor-axis length is 5 or higher, in a proportion of 20% or higher by number.

Description

technical field [0001] The present invention relates to a high-strength hot-rolled steel sheet which is excellent in tensile flangeability and fatigue properties and is suitable as a raw material for automobile running parts. Background technique [0002] From the standpoint of improving the safety of automobiles and increasing fuel costs related to environmental protection, there is an increasing demand for high strength and light weight of hot-rolled steel sheets for automobiles. Among automotive parts, the weight of the frame and arms, which are called the running system, accounts for a high proportion of the total weight of the vehicle body. Therefore, it can be realized by increasing the strength of the raw materials used in these parts and reducing the thickness. lightweight. In addition, from the viewpoint of durability against vibration during running, materials used for the running system are required to have high fatigue properties. [0003] However, with the inc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/00C22C38/14C22C38/38C21D9/46

CPCC21D8/0426C21D9/46C22C38/02C21D9/48C22C38/005C22C38/04C21D2211/002C22C38/001

Inventor 笹井胜浩大桥渡山本研一川崎薰原田宽

Owner NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com