Method for preparing SiC (silicon carbide) coating with fine grains on surface of C/C (carbon/carbon) composite

A carbon composite material and silicon carbide coating technology, which is applied in the field of coating preparation, can solve the problems of poor oxidation resistance and large grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

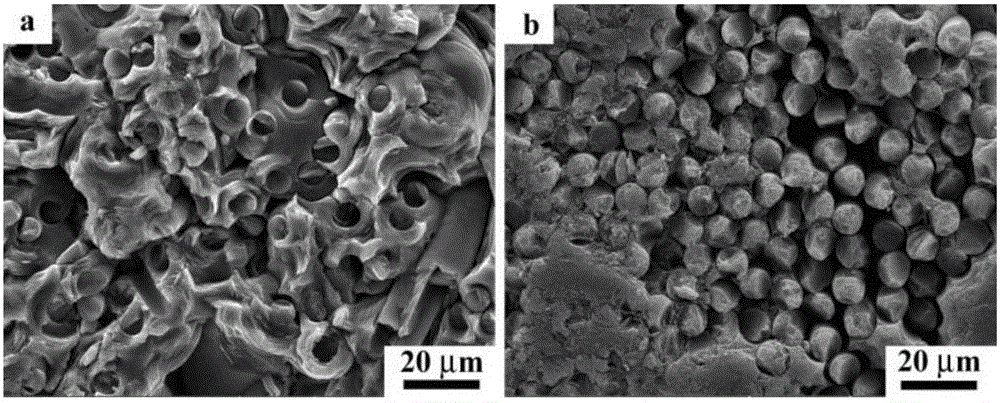

[0025] Step 1: Atomic oxygen oxidation treatment of C / C composite materials, the specific process is:

[0026] 1) The density is 1.68g / cm 3 The 2D C / C composite material was polished with No. 400, No. 600 and No. 1000 sandpaper, and then ultrasonically cleaned with water and absolute ethanol for 20 min, respectively, and dried in a drying oven at 80 °C for 24 h.

[0027] 2) Atomic oxygen oxidation C / C composite material: put the dried C / C composite material into the coaxial atomic oxygen ground simulation test device, the atomic oxygen energy is 5-8eV, and the flux density is 1.0×10 14 -1.0×10 16 atom / (cm 2 ·s), atomic oxygen oxidation treatment for 3h.

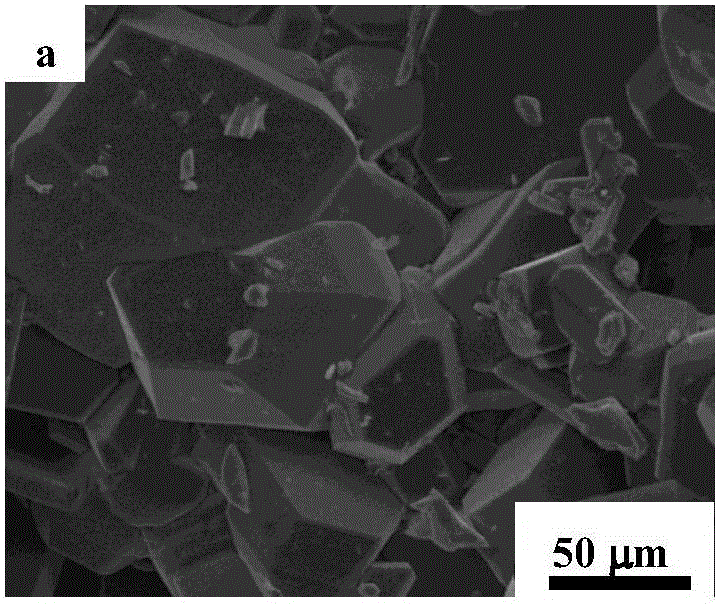

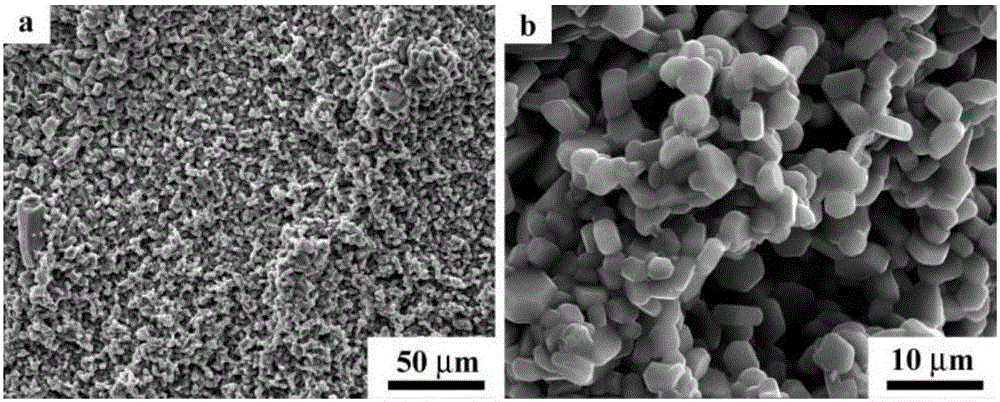

[0028] Step 2: Prepare SiC coating, the specific process is:

[0029] 1) Preparation of silicon carbide coating: the mixed powder of silicon, carbon and alumina is prepared according to mass percentage: silicon, 70%; carbon, 25%; alumina, 5%. Mix the powder and place it in a turpentine ball mill jar, put agate balls of d...

Embodiment 2

[0033] Step 1: Atomic oxygen oxidation treatment of C / C composite materials, the specific process is:

[0034] 1) The density is 1.73g / cm 3 The 2D C / C composite material was chamfered with No. 400, No. 600 and No. 1000 sandpaper, and anhydrous ethanol was used as a solution, ultrasonically cleaned for 20 minutes, and dried in an 80°C drying oven for 24 hours.

[0035] 2) Atomic oxygen oxidation C / C composite material: put the dried C / C composite material into the coaxial source atomic oxygen ground simulation test device, the energy of atomic oxygen is 5-8eV, and the flux density is 1.0×10 14 -1.0×10 16 atom / (cm 2 ·s), atomic oxygen oxidation treatment for 6h.

[0036] Step 2: Prepare SiC coating, the specific process is:

[0037] 1) Preparation of silicon carbide coating: the mixed powder of silicon, carbon and alumina is according to the mass percentage: silicon, 73%; carbon, 15%; alumina, 12%; put the powder into a rosin ball mill after mixing In the process, put differe...

Embodiment 3

[0041] Step 1: Atomic oxygen oxidation treatment of C / C composite materials, the specific process is:

[0042] 1) Set the density to 1.8g / cm 3 The 2D C / C composite material was polished with No. 400, No. 600 and No. 1000 sandpaper, and then ultrasonically cleaned with water and absolute ethanol for 20 min, respectively, and dried in a drying oven at 80 °C for 24 h.

[0043] 2) Atomic oxygen oxidation C / C composite material: put the dried C / C composite material into the coaxial source atomic oxygen ground simulation test device, the energy of atomic oxygen is 5-8eV, and the flux density is 1.0×10 14 -1.0×10 16 atom / (cm 2 ·s), atomic oxygen oxidation treatment for 9h.

[0044] Step 2: Prepare SiC coating, the specific process is:

[0045] 1) Preparation of silicon carbide coating: the mixed powder of silicon, carbon and aluminum oxide is according to the mass percentage: silicon, 83%; carbon, 12%; aluminum oxide: 5%; put the powder into a rosin ball mill tank after mixing I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com