Ultraviolet light assistant preparation method for ferro-electricity film of ferro-electric memory

A technology of ferroelectric memory and ferroelectric thin film, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of device function failure, reduce memory density, etc., and achieve good crystallization performance, small leakage current, and dense surface uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

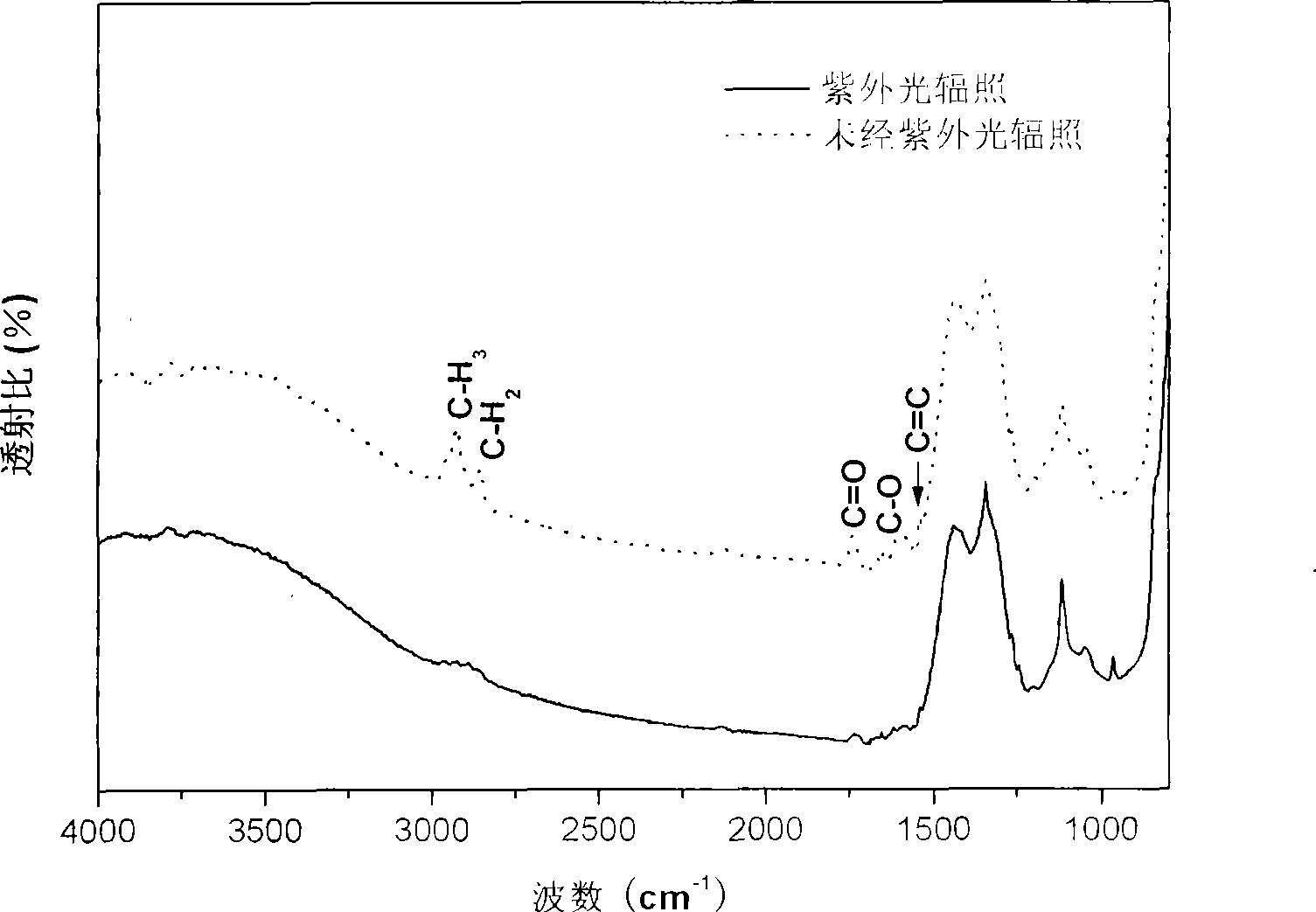

Method used

Image

Examples

preparation example Construction

[0025] The preferred preparation process of the precursor solution is:

[0026] ① Bake lead acetate trihydrate at 100-120°C to remove the crystal water, then dissolve it in ethylene glycol methyl ether, stir and dissolve fully under the heating condition of 70-80°C;

[0027] ② Dissolve zirconium nitrate pentahydrate in formamide, add ethylene glycol methyl ether, stir and dissolve fully under the heating condition of 70-80°C;

[0028] ③Dissolve tetra-n-butyl titanate in acetylacetone, stir and fully dissolve;

[0029] ④ Pour the solution obtained in step ② and step ③ into the solution obtained in step ①, add glacial acetic acid, stir and mix well;

[0030] ⑤Filter the solution obtained in step ④, and add an appropriate amount of ethylene glycol methyl ether to fix the solution, and obtain a golden yellow concentration of 0.1~0.3mol / l Pb 1.06-1.1 Zr 0.3 Ti 0.7 o 3 Precursor solution;

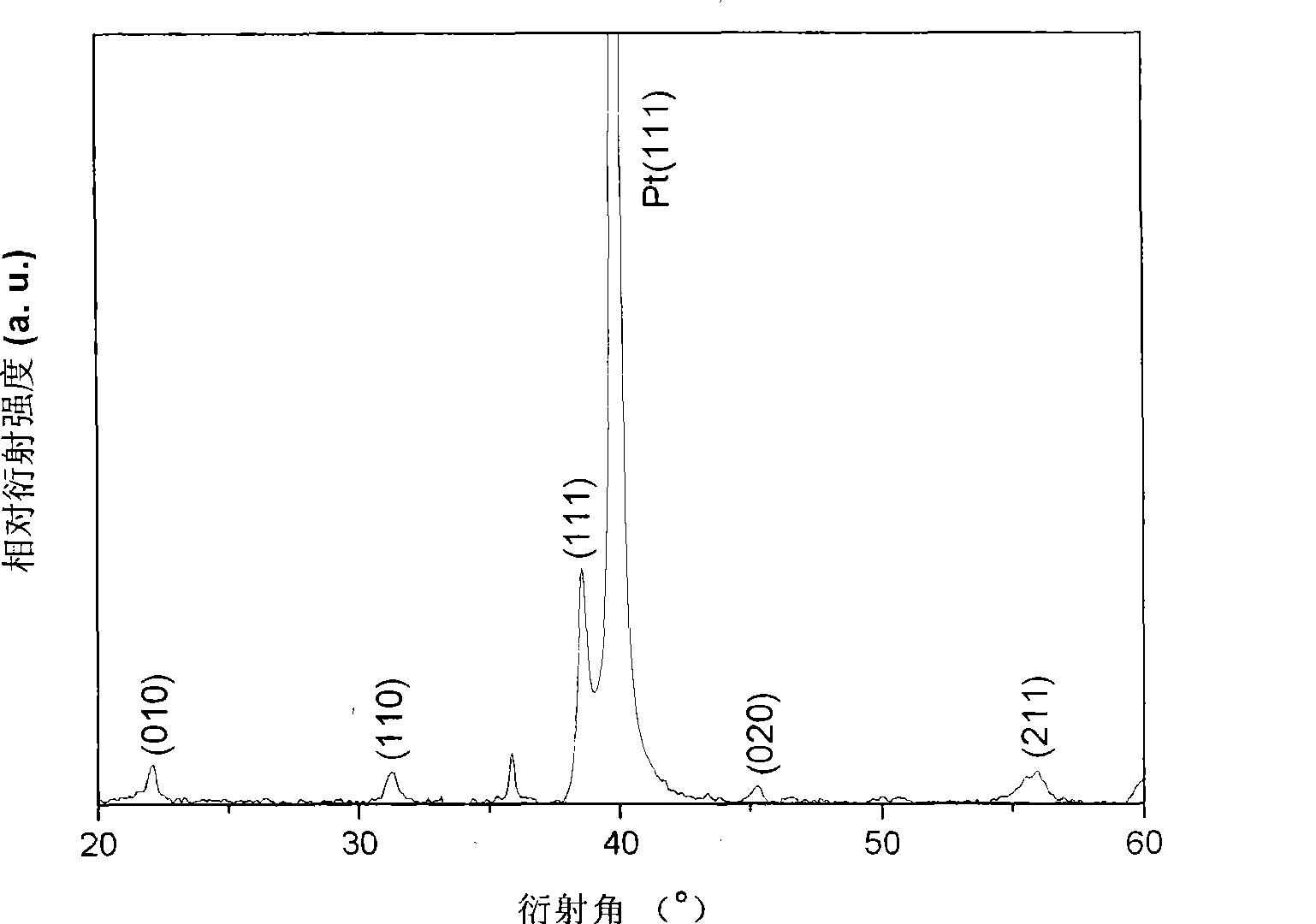

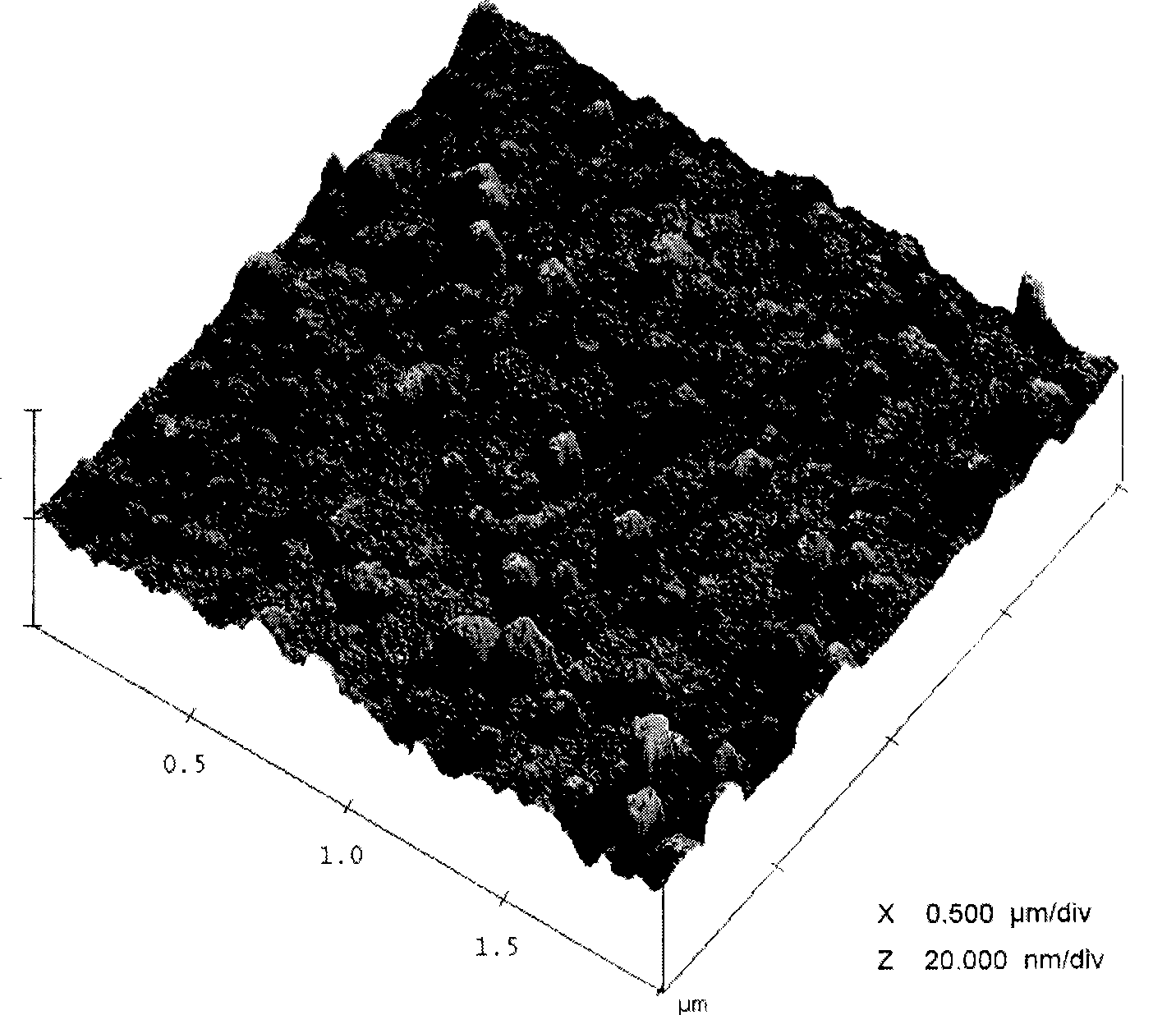

Embodiment 1

[0033] 1) Preparation of Pt / TiO 2 / SiO 2 / Si substrate

[0034] The specific method is:

[0035] 1.1) Surface-treating and cleaning the (100)-oriented p-type silicon substrate p-Si(100) according to a standard semiconductor cleaning process;

[0036] 1.2) using a thermal oxidation method to grow a 150nm thick silicon dioxide barrier layer on the surface of the silicon substrate;

[0037] 1.3) Prepare a 20nm-thick titanium dioxide bonding layer on the silicon dioxide barrier layer by magnetron sputtering. The process conditions of the magnetron sputtering are: sputtering pressure 1.5Pa, sputtering substrate temperature 200°C, sputtering The atmosphere is O 2 : Ar=1:9;

[0038] 1.4) A 150nm-thick electrode metal layer Pt was prepared on the titanium dioxide bonding layer by magnetron sputtering. The process conditions of the magnetron sputtering were: sputtering pressure 1Pa, sputtering substrate temperature 200°C, sputtering atmosphere: Ar gas.

[0039] 2) adopt the foll...

Embodiment 2

[0066] 1) Preparation of Pt / TiO 2 / SiO 2 / Si substrate

[0067] The specific method is:

[0068] 1.1) Surface-treating and cleaning the (100)-oriented p-type silicon substrate p-Si(100) according to a standard semiconductor cleaning process;

[0069] 1.2) using a thermal oxidation method to grow a 150nm thick silicon dioxide barrier layer on the surface of the silicon substrate;

[0070] 1.3) Prepare a 20nm-thick titanium dioxide bonding layer on the silicon dioxide barrier layer by magnetron sputtering. The process conditions of the magnetron sputtering are: sputtering pressure 1.5Pa, sputtering substrate temperature 200°C, sputtering The atmosphere is O 2 : Ar=1:9;

[0071] 1.4) A 150nm-thick electrode metal layer Pt was prepared on the titanium dioxide bonding layer by magnetron sputtering. The process conditions of the magnetron sputtering were: sputtering pressure 1Pa, sputtering substrate temperature 200°C, sputtering atmosphere: Ar gas.

[0072] 2) adopt the foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com