Method for preparing surface-metalized coating of epoxy resin matrix composite material

A composite material and epoxy resin technology, applied in metal material coating process, liquid chemical plating, coating, etc., can solve problems such as poor bonding force, poor surface activity, and peeling of the electroless nickel plating layer, and achieve Excellent binding force, improved binding force, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

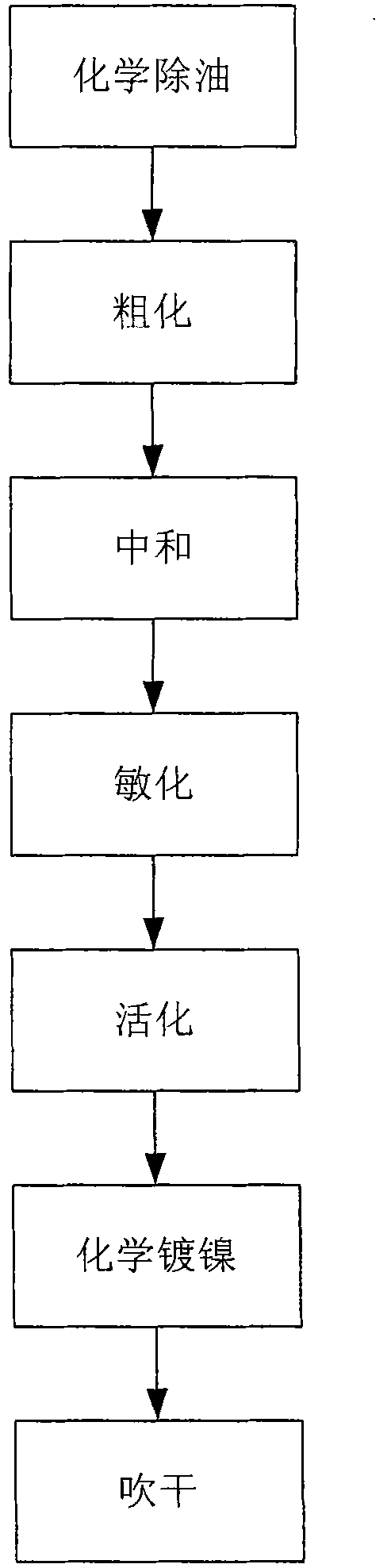

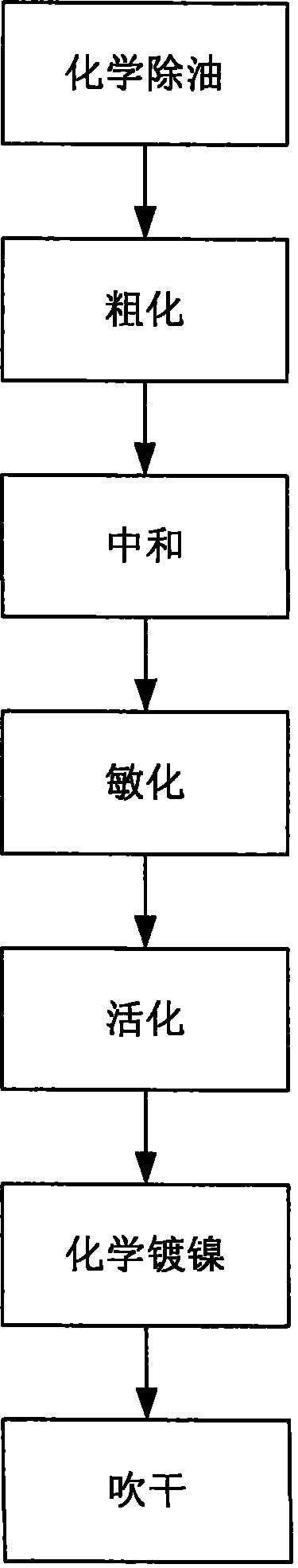

[0030] The present invention as figure 1 shown in the following steps:

[0031] 1. Put the epoxy resin-based composite material into the chemical degreasing tank for alkali washing and degreasing to remove all kinds of oil stains on the surface of the parts. The lye (the solutions are all aqueous solutions, and the remaining components are water, the same below) contains sodium hydroxide 5-10g / L, sodium phosphate 10-40g / L, sodium carbonate 10-20g / L, and the temperature is 50-80°C. The time is 10-30 minutes.

[0032] 2. Use a mixed acid solution to roughen the surface of the material to increase the surface roughness. For epoxy resin-based composite materials, the content of sulfuric acid in the roughening solution is 100-300mL / L, and the content of chromic anhydride is 50-200g / L. The roughening temperature is generally 60-90°C, and the time is 1-5 minutes.

[0033] Roughening is an important process in electroless nickel plating on the surface of epoxy resin-based composite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com