Compound plating solution for obtaining nano compound plating layer with resistance to abrasion and high temperature oxidation, and plating method thereof

A high-temperature oxidation-resistant, composite plating solution technology, applied in coatings, electrolytic coatings, etc., can solve problems affecting the structure and performance of composite coatings, small nanoparticle size, thermodynamic instability, etc., to achieve excellent thermal stability, fine The effect of crystallization, enhanced dispersion strengthening and fine grain strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

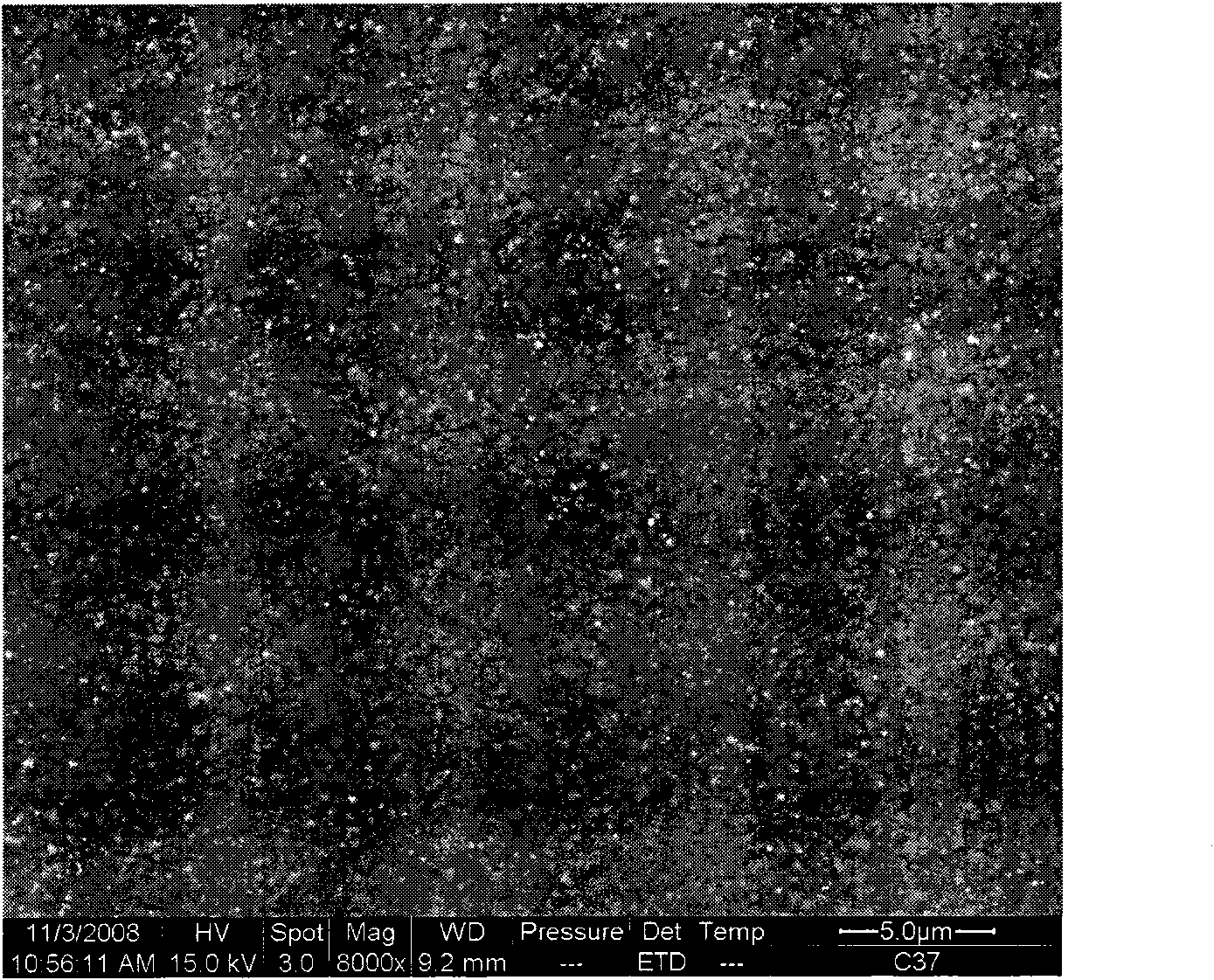

Embodiment 1

[0045] The composite plating solution consists of:

[0046] Ni(NH 2 SO 3 ) 2 4H 2 O 200g / L, NH 4 Cl 15g / L, H 3 BO 3 25g / L, C 12 h 25 SO 4 Na 0.1g / L, nano zirconia particles 30g / L.

[0047] The electroplating method for preparing a composite coating by the composite plating solution comprises the following steps:

[0048] a. Prepare composite plating solution;

[0049] Plating solution is prepared with distilled water, first add weighed boric acid into distilled water, heat to 62°C, stir to dissolve boric acid, then cool to 50°C, add Ni(NH 2 SO 3 ) 2 4H 2 O and NH 4 Cl, stirred, dissolved, and finally added C 12 h 25 SO 4 Na and nano zirconia particles are fully stirred to be formulated with 30g / L of nano zirconia particles, Ni(NH2 SO 3 ) 2 4H 2 O 200g / L, NH 4 Cl 15g / L, H 3 BO 3 25g / L, C 12 h 25 SO 4 Composite plating solution of Na0.1g / L;

[0050] b. Select the cathode substrate and the anode substrate;

[0051] Stainless steel sheet (150mm×20mm×2m...

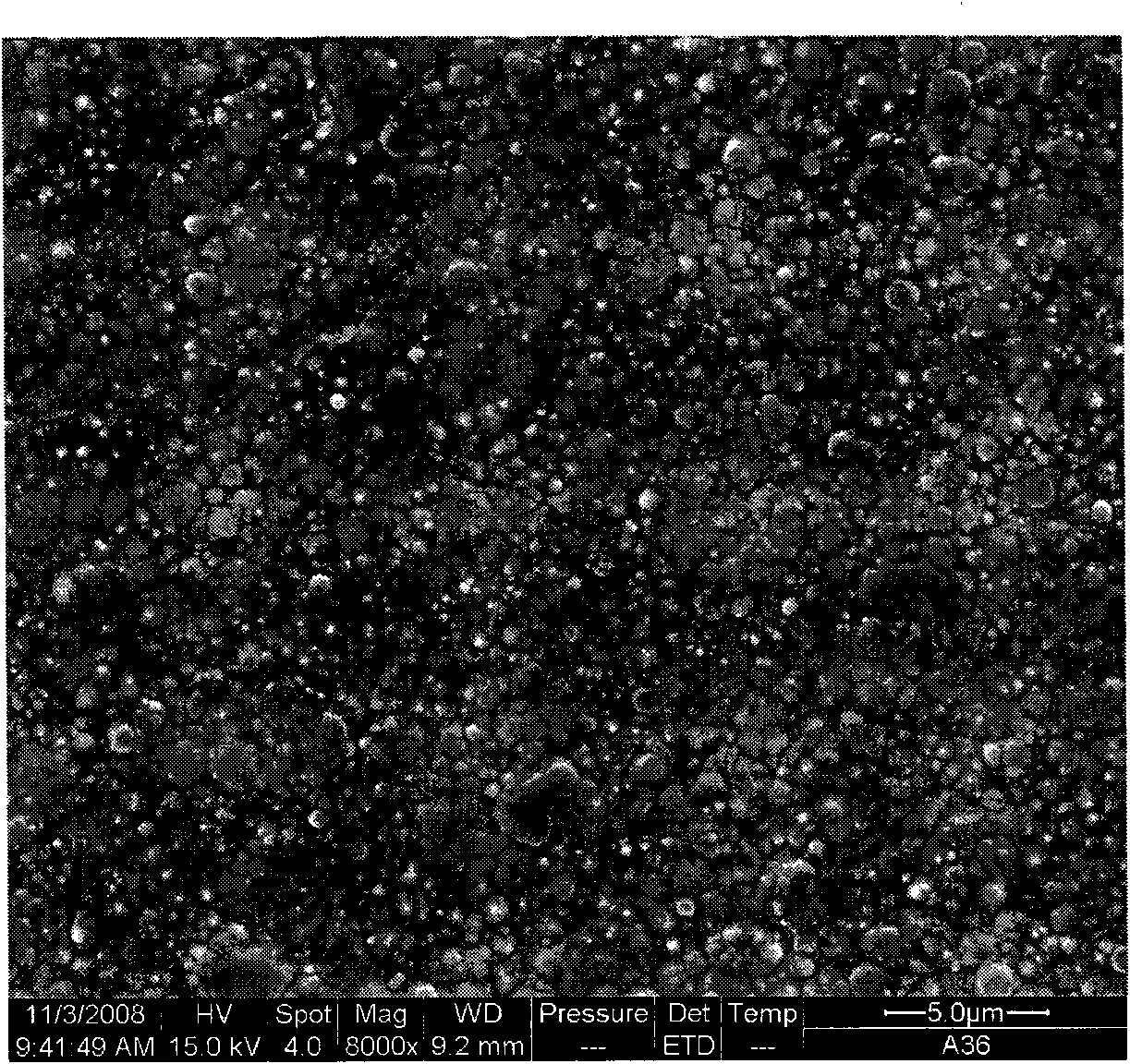

Embodiment 2

[0058] The composite plating solution consists of:

[0059] Ni(NH 2 SO 3 ) 2 4H 2 O 300g / L, NH 4 Cl 5g / L, H 3 BO 3 10g / L, C 12 h 25 SO 4 Na 0.5g / L, nano zirconia particles 5g / L.

[0060] The electroplating method for preparing a composite coating by the composite plating solution comprises the following steps:

[0061] a. Prepare composite plating solution;

[0062] Plating solution is prepared with distilled water, first add weighed boric acid into distilled water, heat to 62°C, stir to dissolve boric acid, then cool to 50°C, add Ni(NH 2 SO 3 ) 2 4H 2 O and NH 4 Cl, stirred, dissolved, and finally added C 12 h 25 SO 4 Na and nano zirconia particles are fully stirred to be prepared with 5g / L of nano zirconia particles, Ni(NH 2 SO 3 ) 2 4H 2 O 300g / L, NH 4 Cl 5g / L, H 3 BO 3 10g / L, C 12 h 25 SO 4 Composite plating solution of Na0.5g / L;

[0063] b. Select the cathode substrate and the anode substrate;

[0064] Copper sheet (150mm×20mm×2mm) is selecte...

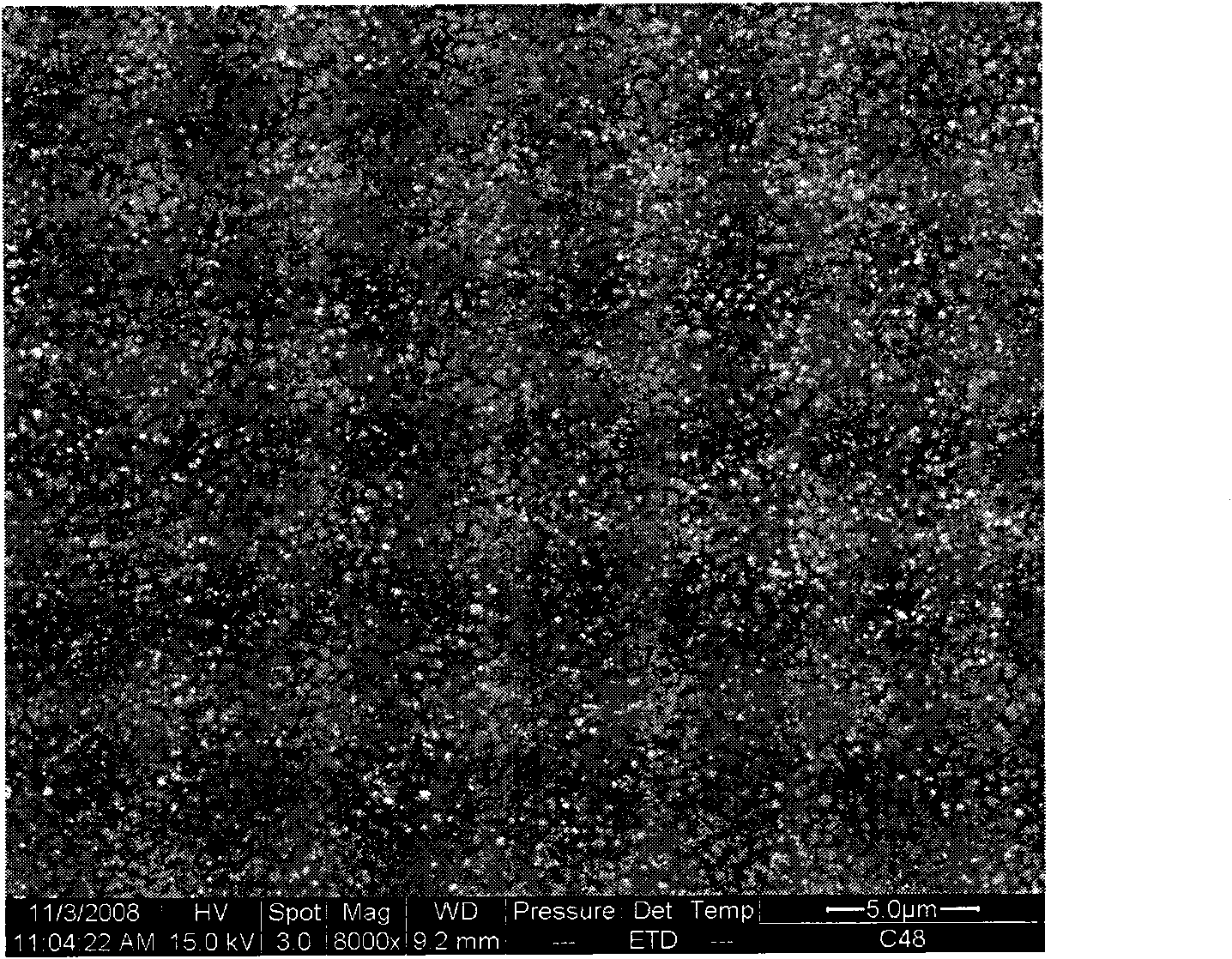

Embodiment 3

[0071] The composite plating solution consists of:

[0072] Ni(NH 2 SO 3 ) 2 4H 2 O 400g / L, NH 4 Cl 25g / L, H 3 BO 3 65g / L, C 12 h 25 SO 4 Na 0.05g / L, nano zirconia particles 45g / L.

[0073] The electroplating method for preparing a composite coating by the composite plating solution comprises the following steps:

[0074] a. Prepare composite plating solution;

[0075] Plating solution is prepared with distilled water, first add weighed boric acid into distilled water, heat to 62°C, stir to dissolve boric acid, then cool to 50°C, add Ni(NH 2 SO 3 ) 2 4H 2 O and NH 4 Cl, stirred, dissolved, and finally added C 12 h 25 SO 4 Na and nano zirconia particles are fully stirred to be formulated with 45g / L of nano zirconia particles, Ni(NH 2 SO 3 ) 2 4H 2 O 400g / L, NH 4 Cl 25g / L, H 3 BO 3 65g / L, C 12 h 25 SO 4 Composite plating solution of Na0.05g / L;

[0076] b. Select the cathode substrate and the anode substrate;

[0077] Stainless steel sheet (150mm×2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com