Ni-P electroless plating solution and preparation method for Ni-P nano cubic boron nitride composite coating

An electroless plating solution and nano-cube technology, applied in liquid electroless plating, coating, metal material coating process, etc., can solve the problems of poor stability of Ni-P electroless plating solution, rough surface of composite coating, complicated preparation process, etc. , to achieve the effect of reducing coating defects, high resistance to oxidation and deterioration, and reducing surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

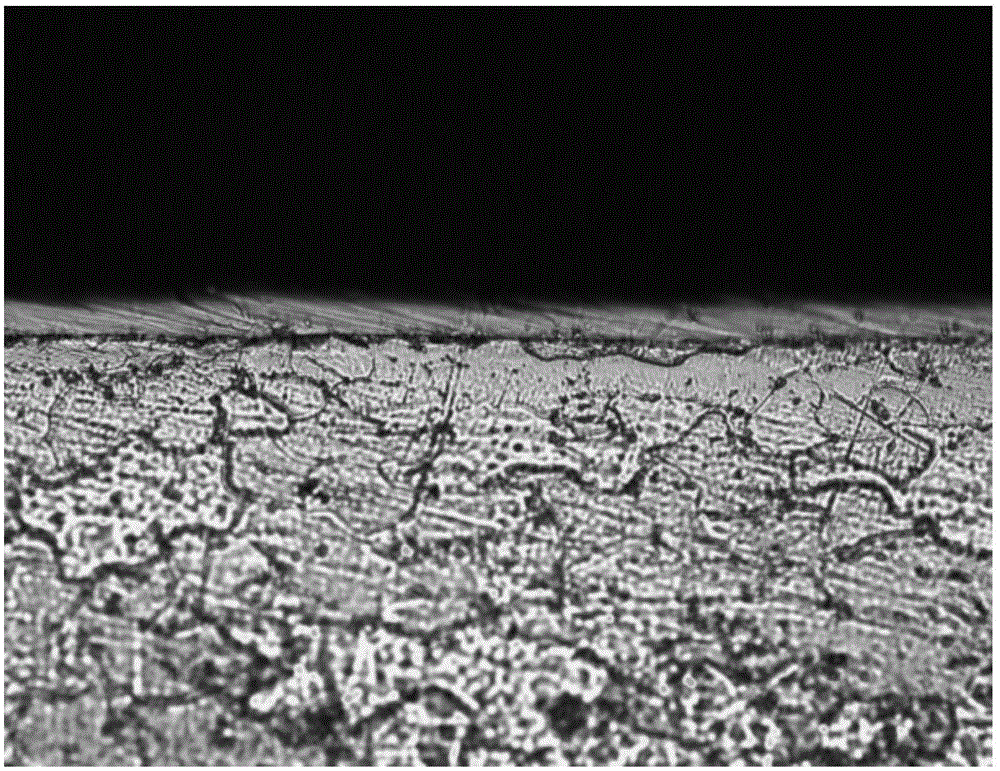

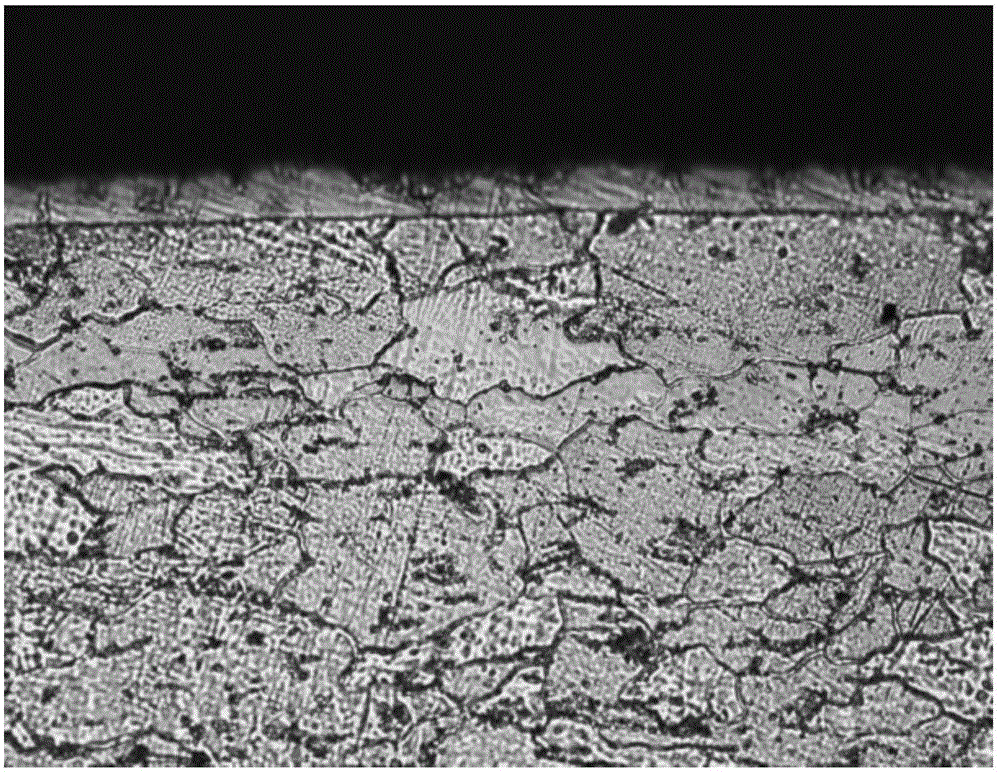

Image

Examples

Embodiment 1

[0026] 1.Ni-P electroless plating solution

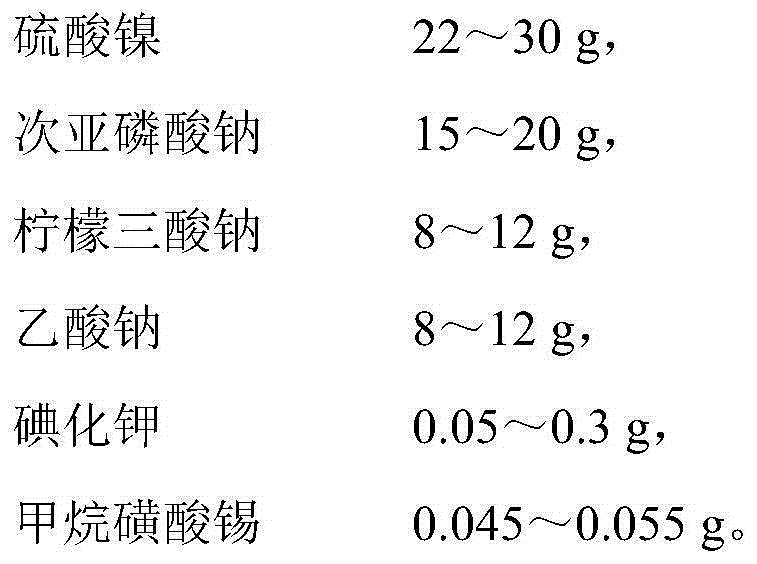

[0027] The Ni-P electroless plating solution of the present embodiment, comprises the component of following weight portion in 1L electroless plating solution:

[0028]

[0029]

[0030] 2. Preparation method of Ni-P nano cubic boron nitride composite coating

[0031] The preparation method of the present embodiment Ni-P nano cubic boron nitride composite coating comprises the following steps:

[0032] 1) The aluminum alloy substrate is ready for use after pretreatment processes such as degreasing, cleaning, pickling and rust removal, cleaning, and weak acid activation. Put the container filled with the plating solution of this embodiment into a water bath and heat it to 80°C, and use H 2 SO 4 Adjust the pH value of plating solution with ammonia water to be 4.5;

[0033] 2) Suspend the substrate to be plated in the plating solution, add nano-cubic boron nitride, the amount of every liter of plating solution is 4ml, and the...

Embodiment 2

[0036] 1.Ni-P electroless plating solution

[0037] The Ni-P electroless plating solution of the present embodiment, comprises the component of following weight portion in 1L electroless plating solution:

[0038]

[0039] 2. Preparation method of Ni-P nano cubic boron nitride composite coating

[0040] The preparation method of the present embodiment Ni-P nano cubic boron nitride composite coating comprises the following steps:

[0041] 1) The aluminum alloy substrate is ready for use after pretreatment processes such as degreasing, cleaning, pickling and rust removal, cleaning, and weak acid activation. Put the container filled with the plating solution of this embodiment into a water bath and heat it to 85°C, and use H 2 SO 4 Adjust the pH value of plating solution with ammonia water to be 4.5;

[0042] 2) Suspend the substrate to be plated in the plating solution, add nano-cubic boron nitride, the amount of every liter of plating solution is 4ml, and the stirring sp...

Embodiment 3

[0045] 1.Ni-P electroless plating solution

[0046] The Ni-P electroless plating solution of the present embodiment, comprises the component of following weight portion in 1L electroless plating solution:

[0047]

[0048] 2. Preparation method of Ni-P nano cubic boron nitride composite coating

[0049] The preparation method of the present embodiment Ni-P nano cubic boron nitride composite coating comprises the following steps:

[0050]1) The aluminum alloy substrate is ready for use after pretreatment processes such as degreasing, cleaning, pickling and rust removal, cleaning, and weak acid activation. Put the container filled with the plating solution of this embodiment into a water bath and heat it to 80°C, and use H 2 SO 4 Adjust the pH value of plating solution with ammonia water to be 4.5;

[0051] 2) Suspend the substrate to be plated in the plating solution, add nano-cubic boron nitride, the addition amount per liter of plating solution is 7ml, and the stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com