A kind of loading preparation method of nanometer metal oxide based on anodic oxidation method

An anodic oxidation method and nano-metal technology, applied in the field of nano-materials, can solve the problems of poor loading effect, cracking and uneven heat shrinkage of powder sintering method and liquid phase deposition method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

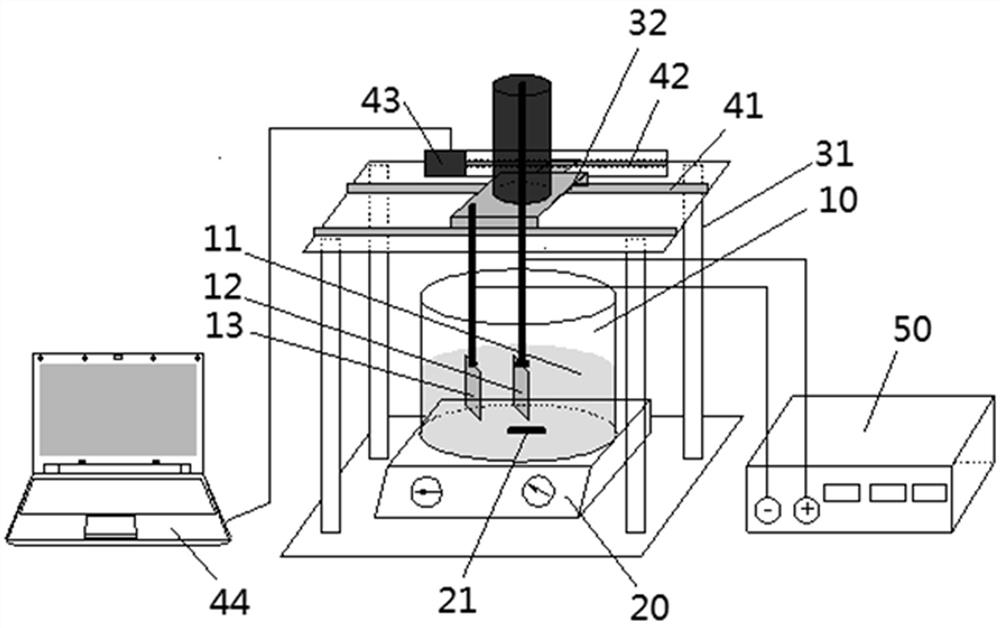

Image

Examples

Embodiment 1

[0044] The carrier uses a stainless steel sheet (3mm×2.5mm×0.3mm), and the anode material is a titanium sheet (3mm×2.5mm×0.3mm), including the following steps:

[0045] The reaction device is built with titanium sheet as the anode material and stainless steel sheet as the cathode material. Take 198 grams (NH 4 ) 2 SO 4 and 7.5 g NH 4 F, add 1.5 liters of distilled water to fully dissolve, and configure the electrolyte. The parameters of the magnetic stirrer are set to 500 rpm, and the magnetic stirrer is turned on to make the rotor stir the electrolyte at a constant speed. Connect the power supply, output constant voltage, set the voltage at 20v, turn on the power supply, and the response time lasts for 1.5 hours. Turn off the power supply and the magnetic stirrer, remove the cathode stainless steel sheet, clean it with deionized water, and obtain the titanium dioxide nanomaterial with the stainless steel sheet as the carrier, and the thickness of the nano film is 120nm. ...

Embodiment 2

[0048] A stainless steel sheet (3mm×2.5mm×0.3mm) is used as the carrier, and a porous titanium plate (3mm×2.5mm×1.5mm, with a pore size of 70 μm) is used as the anode material, including the following steps:

[0049] A reaction device is built with a porous titanium plate as the anode material and a stainless steel sheet as the cathode material. Take 198 grams (NH 4 ) 2 SO 4 and 7.5 g NH 4 F, add 1.5 liters of distilled water to fully dissolve, and configure the electrolyte. The parameters of the magnetic stirrer are set to 750 rpm, and the magnetic stirrer is turned on to make the rotor stir the electrolyte at a constant speed. Connect the power supply, output constant voltage, set the voltage at 20v, turn on the power supply, and the response time lasts for 1 hour. Turn off the power supply and the magnetic stirrer, remove the cathode stainless steel sheet, clean it with deionized water, and obtain the titanium dioxide nanomaterial with the stainless steel sheet as the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com