Method and apparatus of processing magnesium alloy surface utilizing vacuum composite plating film

A composite coating, magnesium alloy technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problems of complex production process, high production cost, environmental pollution, etc., achieve low cost, improve surface Strength, effect of improving finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

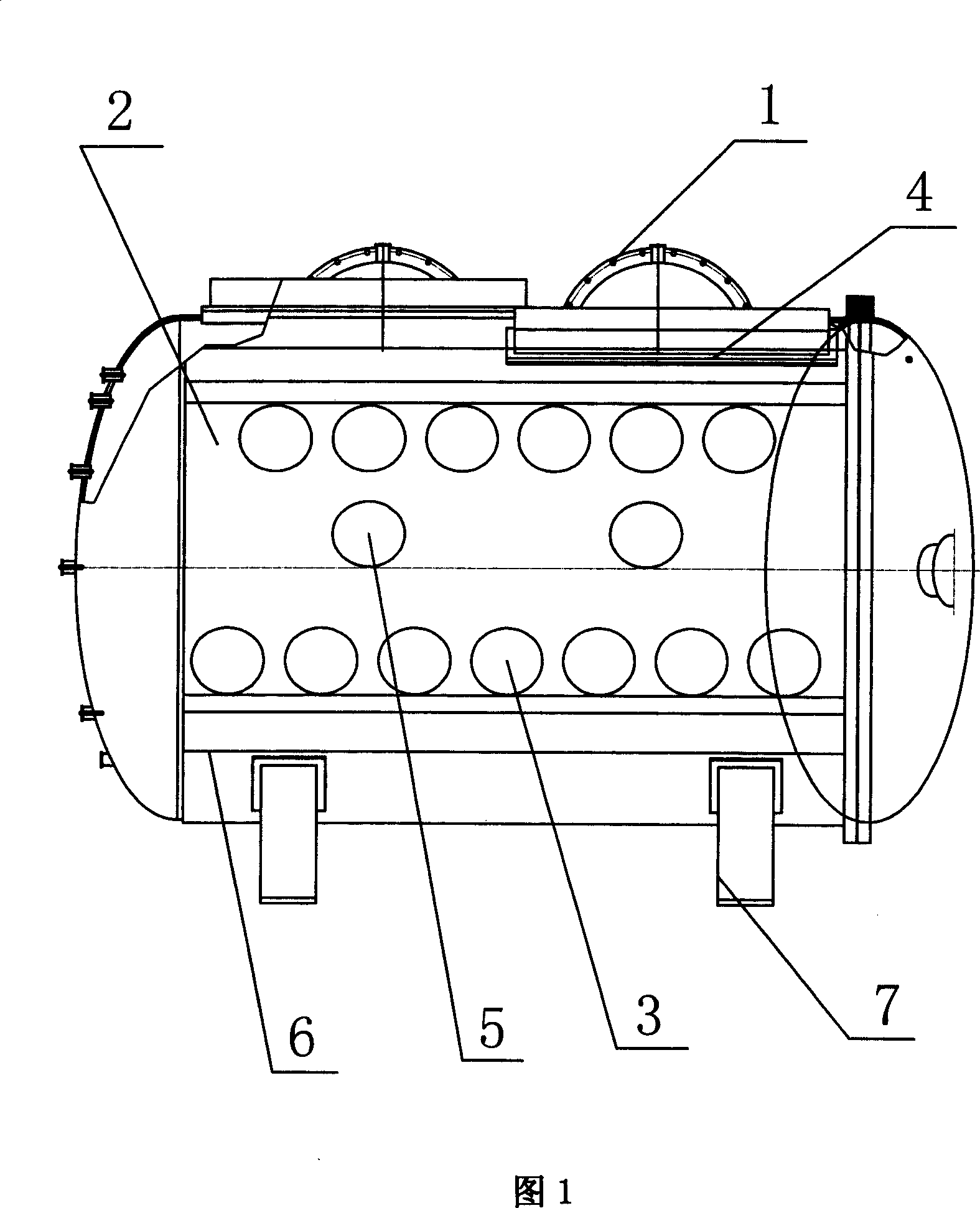

[0029] The device for treating the surface of magnesium alloy with vacuum composite coating (refer to Fig. 1), including the vacuum chamber 2 (specification: 1800mm × 2800mm, which can plate 32 17-inch automobile wheels at a time) fixed by the gauge seat 7 and made of stainless steel, The workpiece rotating car 6 in the center of the vacuum chamber 2 (the workpiece rotating car adopts dynamic sealing technology to access the vacuum chamber through the reducer, and is controlled by computer frequency conversion); A three-stage series structure (not shown) vacuum pumping system 1 is composed of a vacuum pump and a vacuum slide valve pump; 26 arc ion sources 5 and two large plane rectangular magnetron sputtering targets 4 are arranged on the inner wall of the vacuum chamber 2 ( Specification: 1300mm×220mm), of which 26 arc ion sources are intelligent ion coating power supplies with CAN bus interface, which can use high-frequency inverter arc power supply, magnetron sputtering powe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com