Composite middle layer for titanium-based oxide electrode, titanium-based oxide electrode and preparation method of electrode

A composite intermediate layer, titanium-based oxide technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of unsatisfactory binding force and electrode electrocatalysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

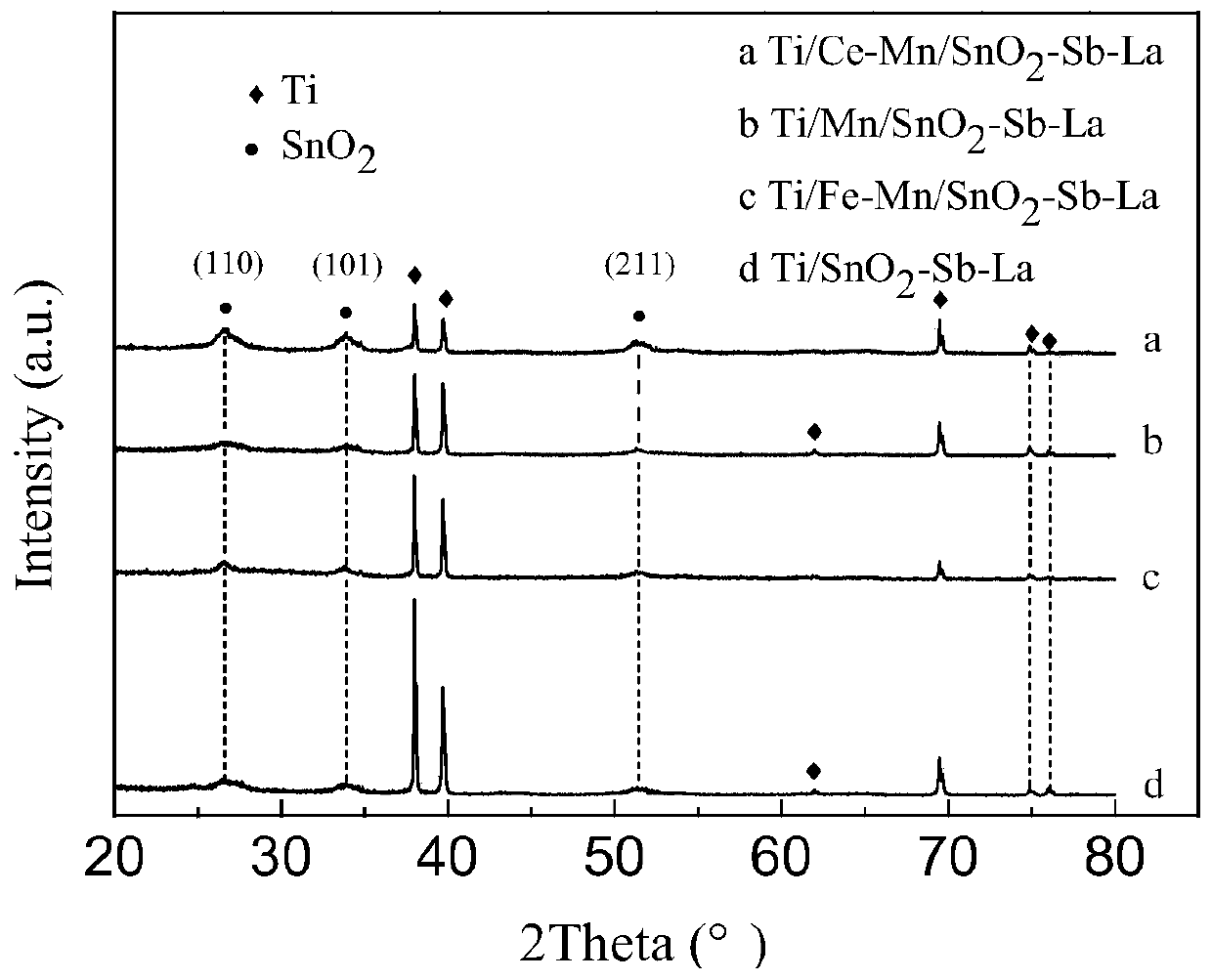

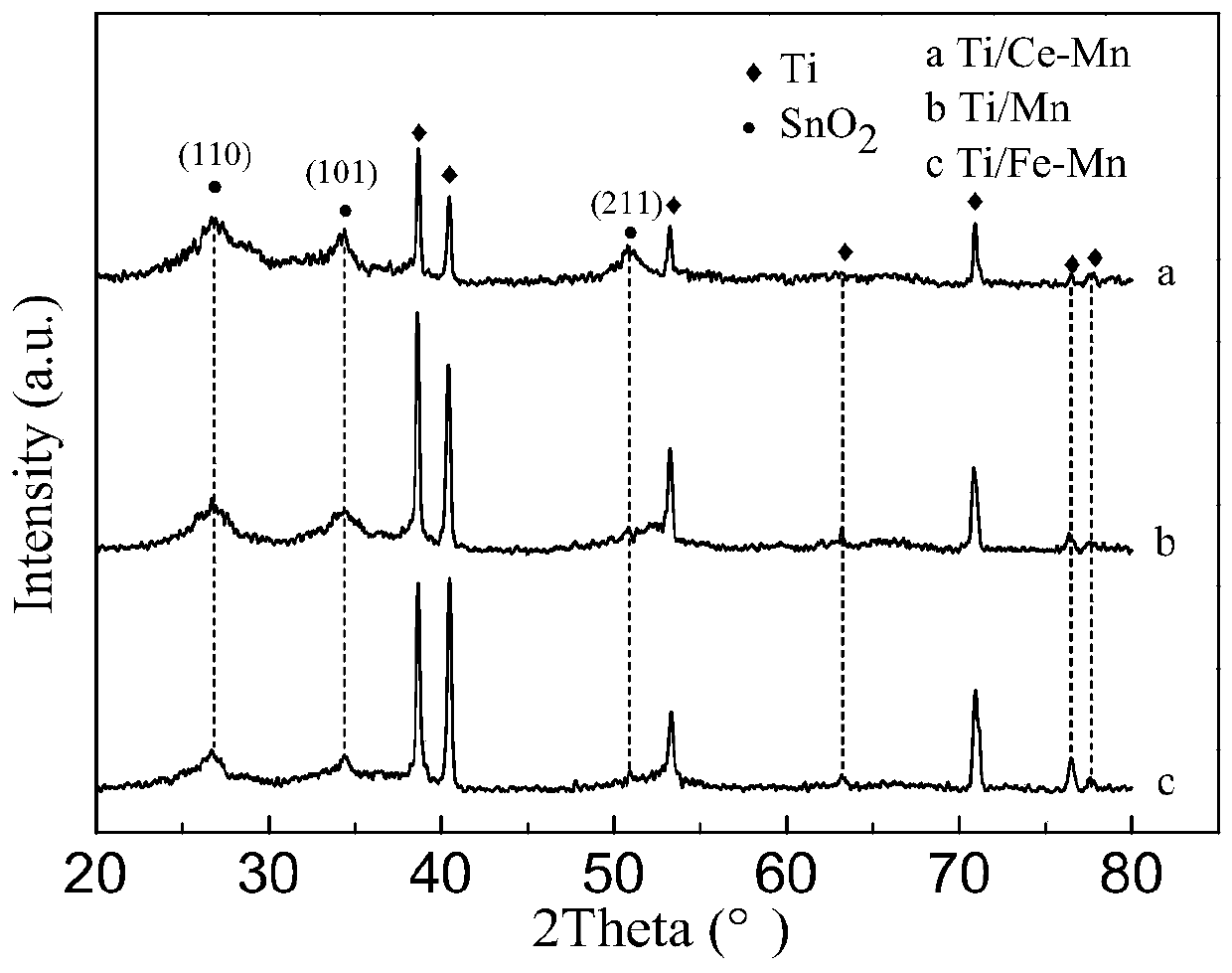

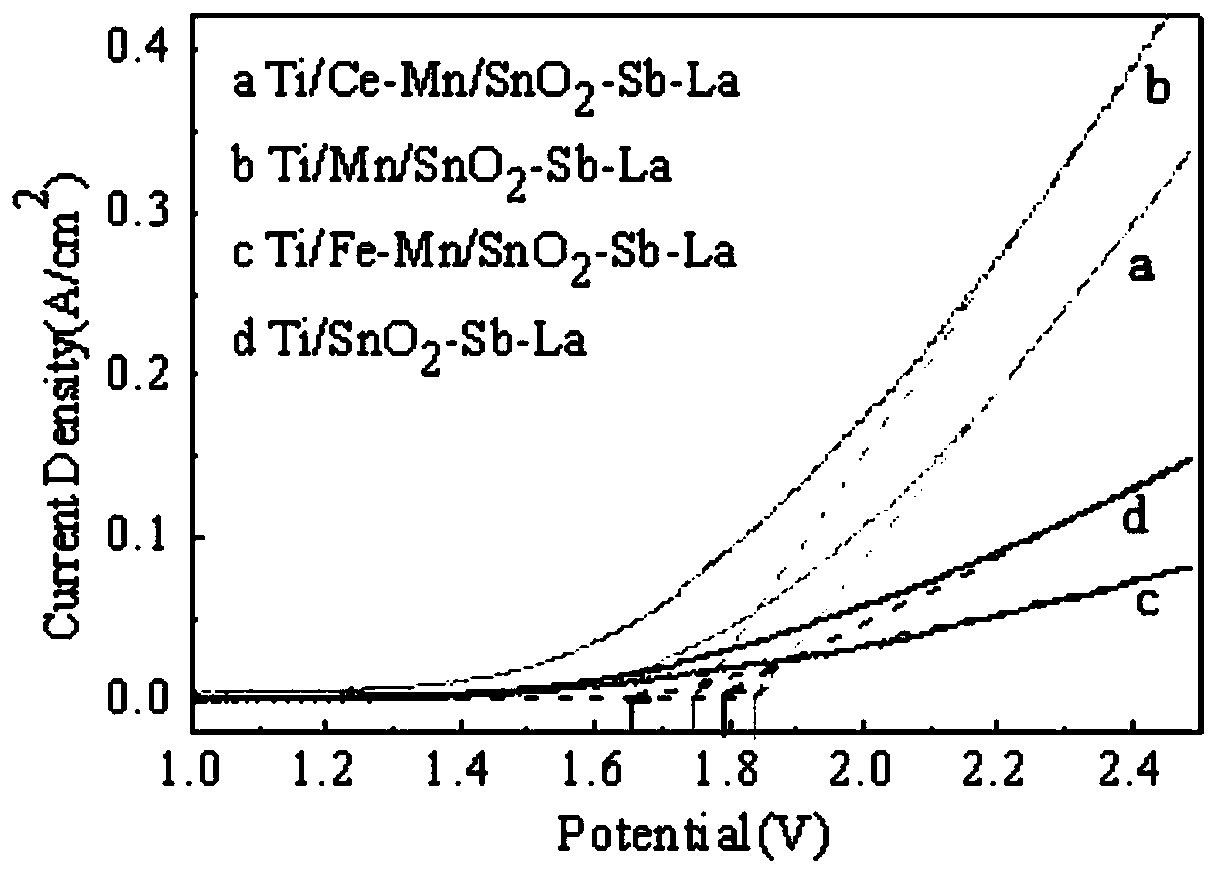

[0035] The present invention provides a method for preparing a titanium-based oxide electrode described in the above technical solution, comprising the following steps:

[0036] (1) SnCl 4 , SbCl 3 , Mn(NO 3 ) 3 , Ce(NO 3 ) 3 Mixing with ethanol to obtain a first mixed ethanol solution, mixing the first mixed ethanol solution with hydrochloric acid and then aging to obtain an intermediate layer sol-gel coating solution;

[0037] (2) SnCl 4 , SbCl 3 、LaCl 3 Mixing with ethanol to obtain a second mixed ethanol solution, mixing the second mixed ethanol solution with hydrochloric acid and then aging to obtain an active layer sol-gel coating solution;

[0038] (3) coating the sol-gel coating solution of the intermediate layer in the step (1) on the surface of the titanium substrate, and then performing drying and thermal oxidation treatment successively to obtain a composite intermediate layer;

[0039] (4) Apply the active layer sol-gel coating liquid in the step (2) to t...

Embodiment 1

[0056] (1) Pretreatment of titanium substrate surface: 50mm×30mm×3mm titanium plates were polished with 180-mesh, 240-mesh, and 400-mesh sandpaper of different thickness and fineness, and then ultrasonicated in acetone for 30 minutes, then put in 10% hydrogen Heating in a water bath in sodium oxide solution for 1 hour, and finally slightly boiling in 10% oxalic acid solution for 2 hours;

[0057] (2) Preparation of intermediate layer coating solution: prepare SnCl with a molar concentration of 1mol / L 4 ·5H 2 O, the SbCl of 0.1mol / L 3 , 0.02mol / L Mn(NO 3 ) 3 and 0.02mol / L Ce(NO 3 ) 3 ·6H 2 O mixed ethanol solution, and then add an appropriate amount of dilute hydrochloric acid, stand and age for 3 hours before painting;

[0058] (3) Preparation of active layer coating solution: prepare SnCl with a molar concentration of 1mol / L 4 ·5H 2O, the SbCl of 0.1mol / L 3 and 0.015mol / L LaCl 3 ·7H 2 The mixed ethanol solution of O, other preparation methods are the same as (2); ...

Embodiment 2

[0109] Mn(NO in the embodiment 1 step (2) 3 ) 3 The concentration is changed to 0.05mol / L, Ce(NO 3 ) 3 ·6H 2 The concentration of O was changed to 0.02mol / L respectively, and the rest were the same as in Example 1 to obtain Ti / Ce-Mn / SnO 2 -Sb-La titanium based oxide electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com