Material additive manufacturing method of square hole pipeline aluminum alloy part

A technology of additive manufacturing of aluminum alloy parts, which is applied in the direction of additive manufacturing, additive processing, and improvement of process efficiency. Production efficiency, effect of avoiding surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The present embodiment provides an additive manufacturing method for an aluminum alloy part of a square hole pipeline, comprising the following steps:

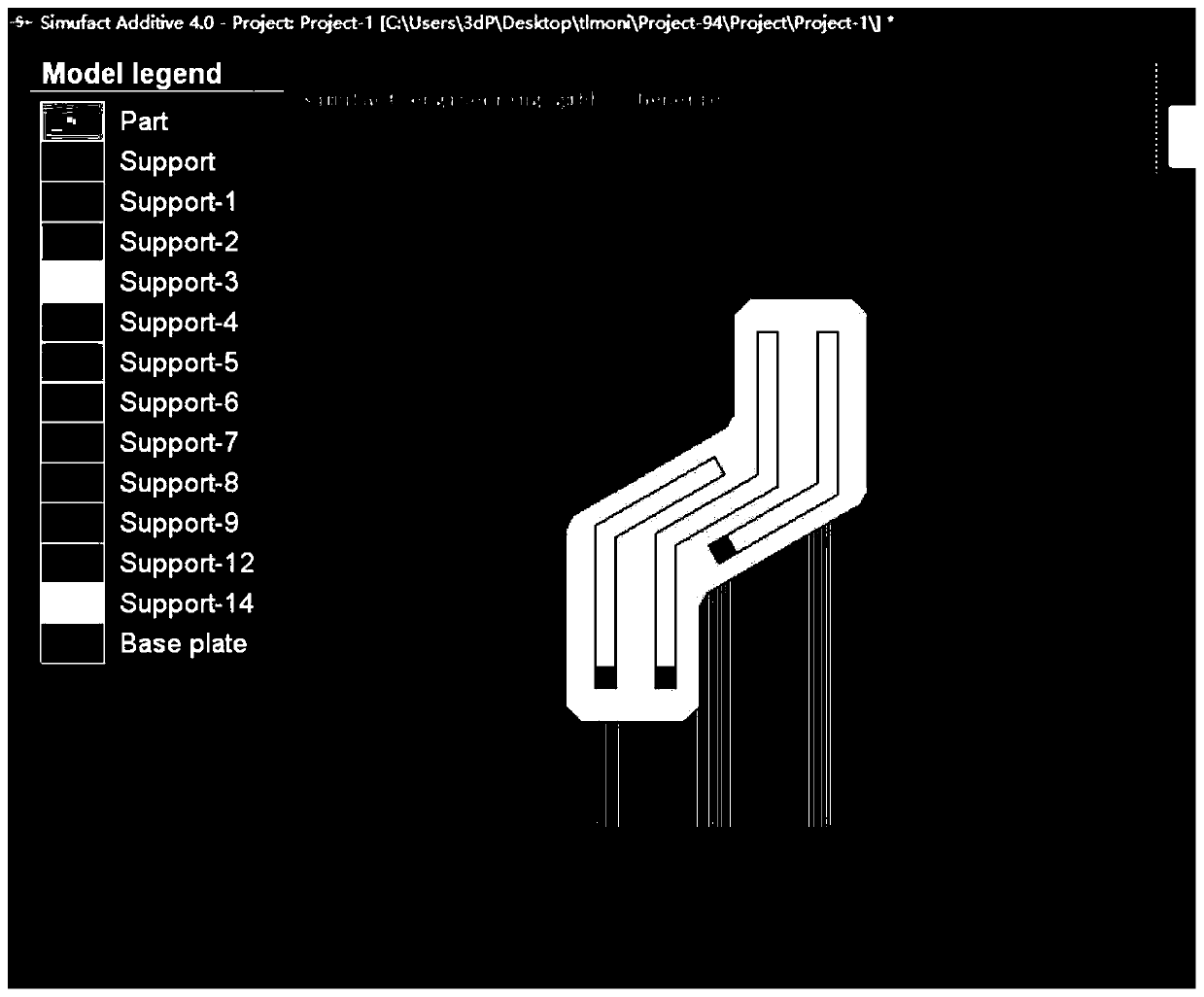

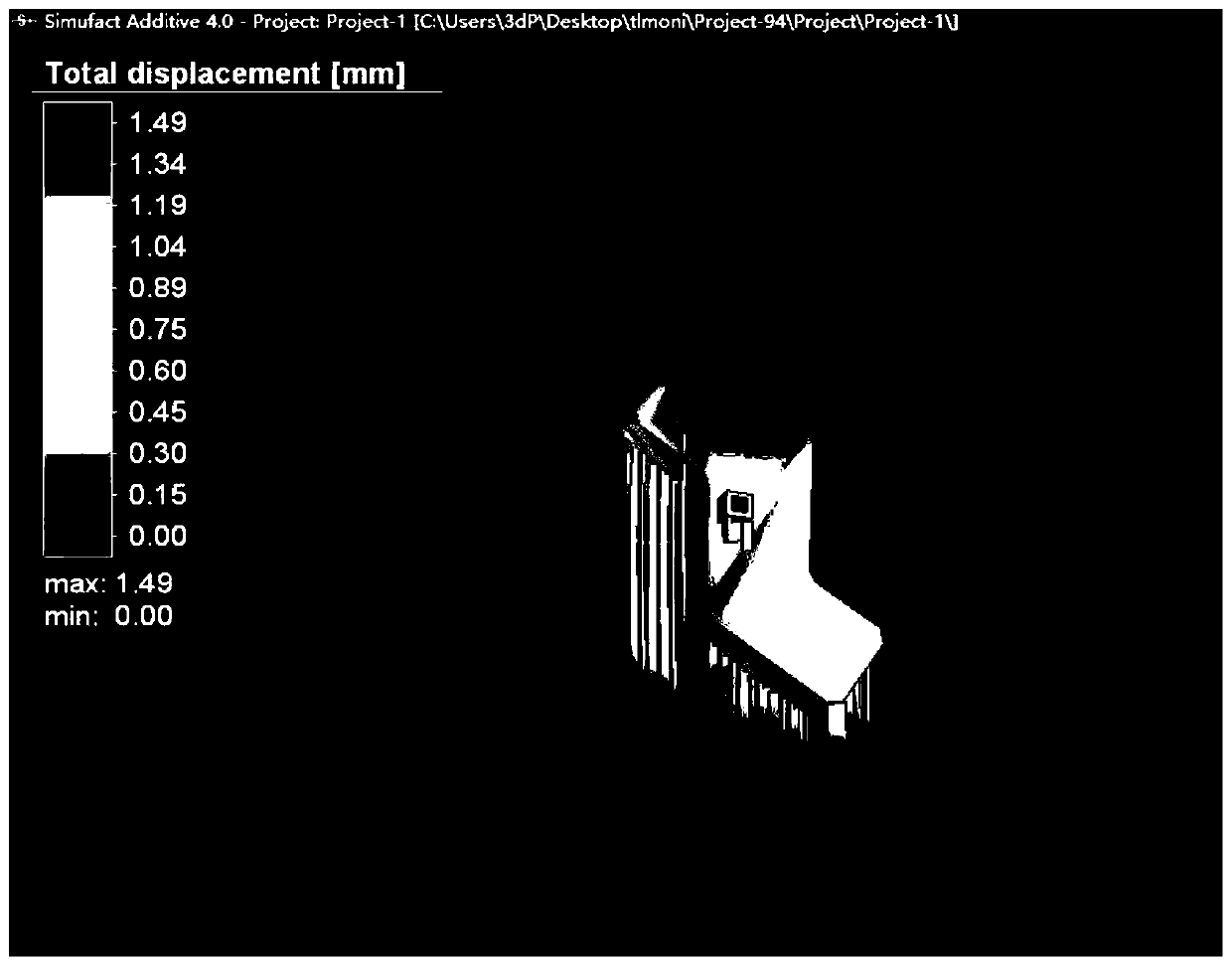

[0046] Step 1) Prepare the aluminum alloy printing substrate. Before printing, polish the aluminum alloy substrate with 1200-grit sandpaper to remove the oxide on the surface of the aluminum alloy substrate. At the same time, when simulating the printing process of the part, in order to reduce the deformation, it is necessary to consider the substrate during printing. The deformation that occurs in the process is compensated for deformation, so as to obtain parts with higher precision.

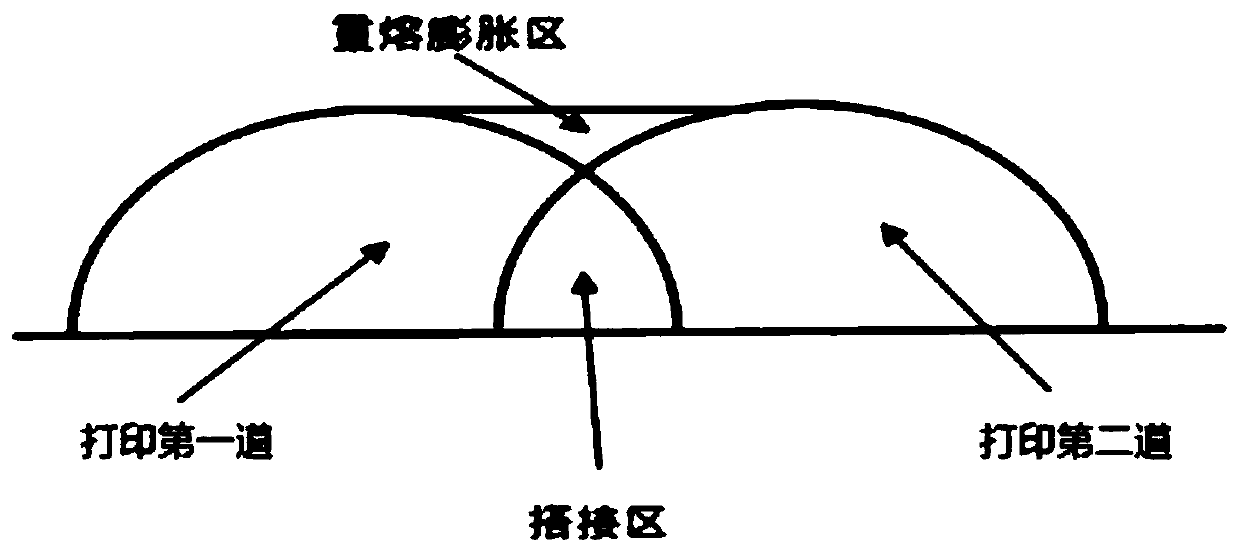

[0047] Step 2) Create a three-dimensional model of an aluminum alloy part with a square hole pipe, and add mesh support and layered slicing to the three-dimensional model of the square hole pipe aluminum alloy part to obtain a slice model of the square hole pipe aluminum alloy part. Import the sliced model into the 3D printing molding...

Embodiment 2

[0057] The invention provides an additive manufacturing method for aluminum alloy parts of a square hole pipeline, comprising the following steps:

[0058] Step 1) Prepare the aluminum alloy printing substrate. Before printing, polish the aluminum alloy substrate with 1200-grit sandpaper to remove the oxide on the surface of the aluminum alloy substrate. At the same time, when simulating the printing process of the part, in order to reduce the deformation, it is necessary to consider the substrate during printing. The deformation that occurs in the process is compensated for deformation, so as to obtain parts with higher precision.

[0059] Step 2) Create a three-dimensional model of an aluminum alloy part with a square hole pipe, and add mesh support and layered slicing to the three-dimensional model of the square hole pipe aluminum alloy part to obtain a slice model of the square hole pipe aluminum alloy part. Import the sliced model into the 3D printing molding equipment:...

Embodiment 3

[0069] The present embodiment provides an additive manufacturing method for an aluminum alloy part of a square hole pipeline, comprising the following steps:

[0070] Step 1) Prepare the aluminum alloy printing substrate. Before printing, polish the aluminum alloy substrate with 1200-grit sandpaper to remove the oxide on the surface of the aluminum alloy substrate. At the same time, when simulating the printing process of the part, in order to reduce the deformation, it is necessary to consider the substrate during printing. The deformation that occurs in the process is compensated for deformation, so as to obtain parts with higher precision.

[0071] Step 2) Create a three-dimensional model of an aluminum alloy part with a square hole pipe, and add mesh support and layered slicing to the three-dimensional model of the square hole pipe aluminum alloy part to obtain a slice model of the square hole pipe aluminum alloy part. Import the sliced model into the 3D printing molding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com