Preparation method for nano-composite high-tin copper alloy electroplating material

A tin-copper alloy, nano-composite technology, used in electrolytic coatings, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

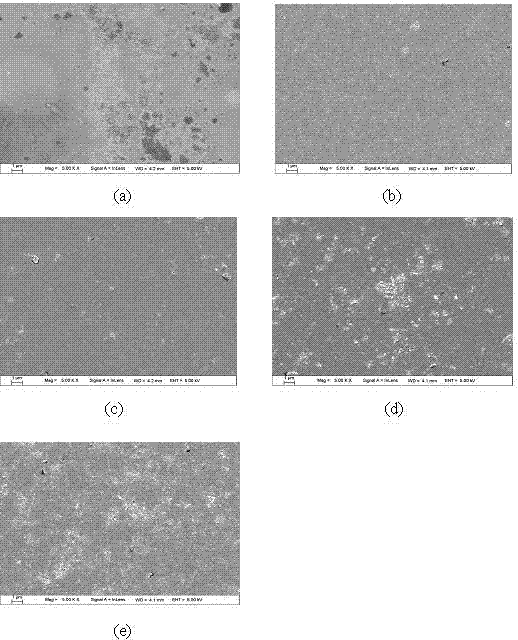

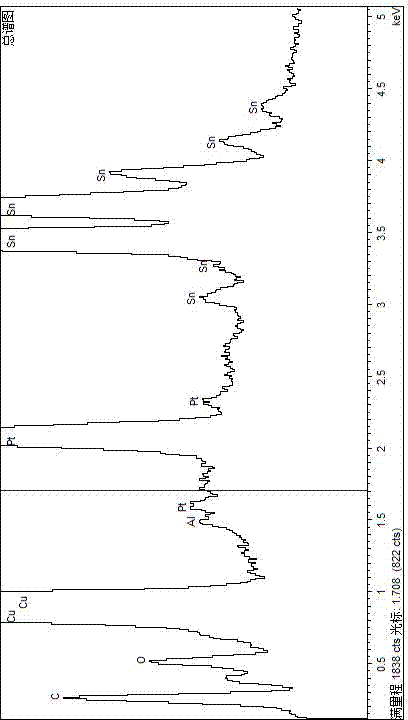

Image

Examples

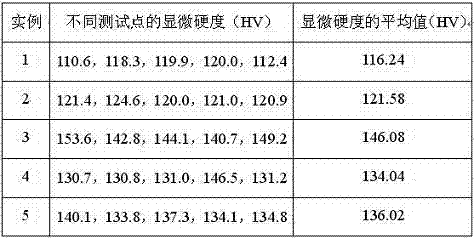

Embodiment 1

[0022] Plating solution formula: Cu 2 P 2 o 7 5g, Sn 2 P 2 o 7 1.6g, K 4 P 2 o 7 50g, K 2 HPO 4 16g, the bath volume is 200ml.

[0023] Plating solution preparation: weigh the required amount of K 4 P 2 o 7 Put it into a beaker, add an appropriate amount of distilled water, and after it is completely dissolved under magnetic stirring, add the required Cu 2 P 2 o 7 Stir to dissolve the solid until the solution is clear, then add the weighed Sn 2 P 2 o 7 , then add the required amount of conductive salt K 2 HPO 4 , and then add an appropriate amount of distilled water, and under stirring conditions, dropwise add phosphoric acid solution to neutralize the solution until the pH reaches 8.8, leave it for a while until the plating solution turns dark blue and clear, pour it into the plating tank, and use air to stir during the electroplating process.

[0024] The method for preparing a composite coating by the composite plating solution comprises the f...

Embodiment 2

[0032] Plating solution formula: Al 2 o 3 Nano powder 0.8g, Cu 2 P 2 o 7 5g, Sn 2 P 2 o 7 1.6g, K 4 P 2 o 7 50g, K 2 HPO 4 16g, the bath volume is 200ml.

[0033] Plating solution preparation: weigh the required amount of K 4 P 2 o 7 Put it into a beaker, add an appropriate amount of distilled water, and after it is completely dissolved under magnetic stirring, add the required Cu 2 P 2 o 7 Stir to dissolve the solid until the solution is clear, then add the weighed Sn 2 P2 o 7 , then add the required amount of conductive salt K 2 HPO 4 , adding nano-Al 2 o 3 , and then add an appropriate amount of distilled water, under stirring conditions, dropwise add phosphoric acid solution to neutralize the solution until the pH reaches 8.8, pour it into the plating tank, and use air stirring during the electroplating process.

[0034] The method for preparing a composite coating by the composite plating solution comprises the following steps:

[0035] ...

Embodiment 3

[0042] Plating solution formula: Al 2 o 3 Nano powder 1.6g, Cu 2 P 2 o 7 5g, Sn 2 P 2 o 7 1.6g, K 4 P 2 o 7 50g, K 2 HPO 4 16g, the bath volume is 200ml.

[0043] Plating solution preparation: weigh the required amount of K 4 P 2 o 7 Put it into a beaker, add an appropriate amount of distilled water, and after it is completely dissolved under magnetic stirring, add the required Cu 2 P 2 o 7 Stir to dissolve the solid until the solution is clear, then add the weighed Sn 2 P 2 o 7 , then add the required amount of conductive salt K 2 HPO 4 , adding nano-Al 2 o 3 , add an appropriate amount of distilled water, and under stirring conditions, add phosphoric acid solution dropwise to neutralize the solution until the pH reaches 8.9, pour it into the plating tank, and use air stirring during the electroplating process.

[0044] The method for preparing a composite coating by the composite plating solution comprises the following steps:

[0045] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com