Nb coated NiTi shape memory composite material and preparation method thereof

A composite material and memory alloy technology, which is applied in the field of Nb-coated NiTi shape memory composite material and its preparation, can solve the problems of being difficult to satisfy and limit the application at the same time, and achieve the effects of good quality, dense and uniform surface, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment is prepared through the following steps:

[0034] (1) Selection of raw materials.

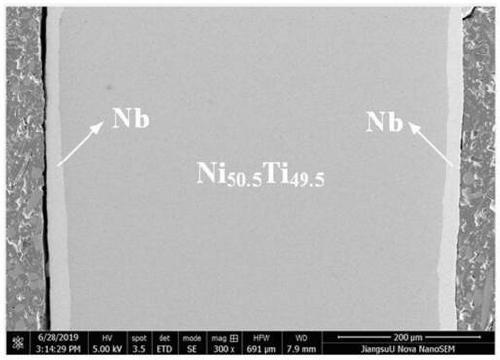

[0035] Core material: Ni50.5 Ti 49.5 Alloy; surface shell material: high-purity Nb (99.95%, mass percentage).

[0036] (2) Nb coated Ni 50.5 Ti 49.5 Preparation of shape memory composites.

[0037] ① Raw material cutting. Using the method of electric discharge cutting from Ni 50.5 Ti 49.5 On the pure Nb blank, cut a 60mm×60mm×4.5mm NiTi core plate and two 60mm×60mm×0.2mm pure Nb shell plates;

[0038] ② Cleaning of raw materials. The surface of the NiTi alloy plate and pure Nb plate obtained after cutting is mechanically polished to a mirror surface with 400#, 800#, and 1200# sandpaper in sequence, and then ultrasonically cleaned in alcohol and acetone respectively, and stored in a sealed bag after drying;

[0039] ③Making of wrapping and stacking rolling bales. According to pure Nb superstrate / Ni 50.5 Ti 49.5 The order of the core material plate / pure N...

Embodiment 2

[0047] The present embodiment is prepared through the following steps:

[0048] (1) Selection of raw materials.

[0049] Core material: Ni 50.8 Ti 49.2 Alloy; surface shell material: high-purity Nb (99.95%, mass percentage).

[0050] (2) Nb coated Ni 50.8 Ti 49.2 Preparation of shape memory composites.

[0051] ① Raw material cutting. Using the method of electric discharge cutting from Ni 50.8 Ti 49.2 And on the pure Nb blank, cut a 65mm×65mm×5mm NiTi core board and two 65mm×65mm×0.25mm pure Nb shell boards;

[0052] ② Cleaning of raw materials. The surface of the NiTi alloy plate and pure Nb plate obtained after cutting is mechanically polished to a mirror surface with 400#, 800#, and 1200# sandpaper in sequence, and then ultrasonically cleaned in alcohol and acetone respectively, and stored in a sealed bag after drying;

[0053] ③Making of wrapping and stacking rolling bales. According to pure Nb superstrate / Ni 50.8 Ti 49.2 The order of the core material plate / p...

Embodiment 3

[0061] The present embodiment is prepared through the following steps:

[0062] (1) Selection of raw materials.

[0063] Core material: Ni 51.0 Ti 49.0 Alloy; surface shell material: high-purity Nb (99.95%, mass percentage).

[0064] (2) Nb coated Ni 51.0 Ti 49.0 Preparation of shape memory composites.

[0065] ① Raw material cutting. Using the method of electric discharge cutting from Ni 51.0 Ti 49.0 On the pure Nb blank, cut a 70mm×70mm×5.5mm NiTi core plate and two 70mm×70mm×0.3mm pure Nb shell plates;

[0066] ② Cleaning of raw materials. The surface of the NiTi alloy plate and pure Nb plate obtained after cutting is mechanically polished to a mirror surface with 400#, 800#, and 1200# sandpaper in sequence, and then ultrasonically cleaned in alcohol and acetone respectively, and stored in a sealed bag after drying;

[0067] ③Making of wrapping and stacking rolling bales. According to pure Nb superstrate / Ni 51.0 Ti 49.0 The order of the core material plate / pure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com