Jet angle controllable ultrasonic droplet jetting additive manufacturing device and method

A technology of additive manufacturing and droplet injection, which is applied in the field of additive manufacturing and can solve problems such as low precision, easy clogging and cleaning, and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

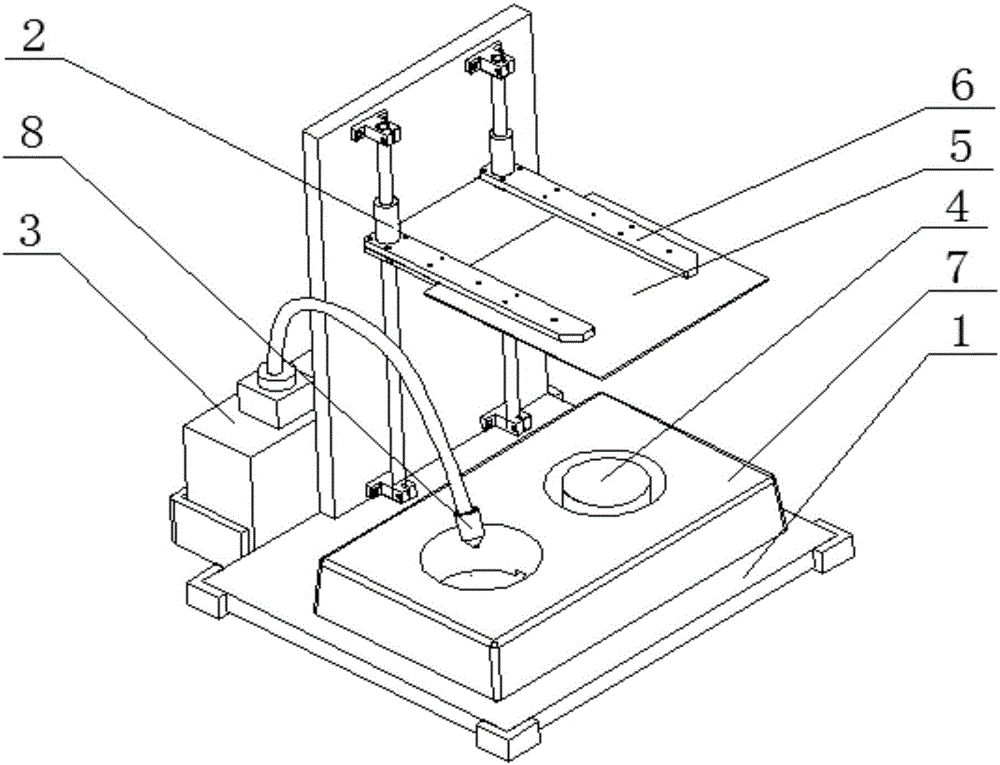

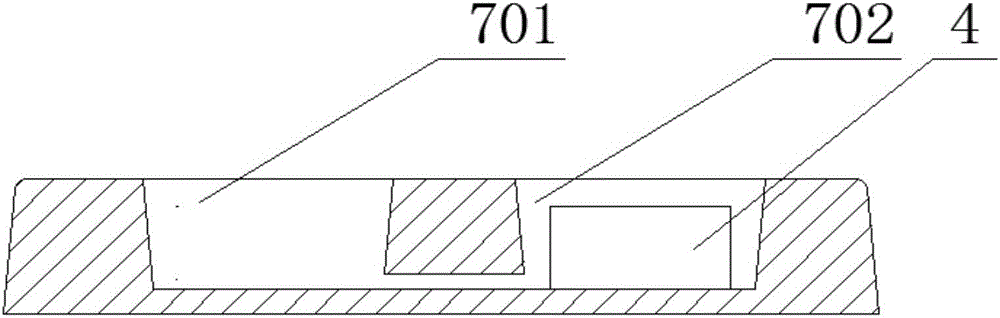

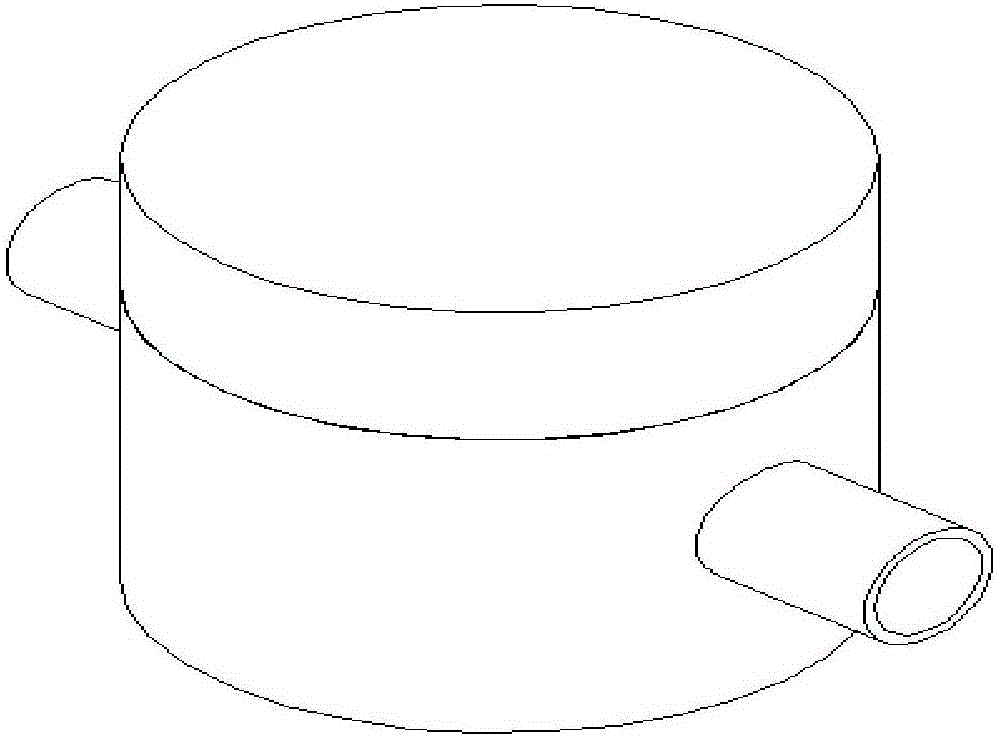

[0045]It includes a base 1, a Z-direction workbench 2, a high-precision syringe pump 3, a focused ultrasonic transducer 4, a substrate 5, a film holder 6, a liquid container 7, and a feeding head 8. The base 1 is installed at the bottom, and the liquid container The jet pool 702 of 7 is installed on the base 1, the focused ultrasonic transducer 4 is installed in the jet pool 702, the base plate 5 is fixed under the wafer platform 6 and above the jet pool 702, and the wafer platform 6 is installed on the Z-direction workbench 2, the Z-direction workbench 2 is installed on the base 1, the jet pool 702 and the liquid storage pool 701 of the liquid container 7 communicate with each other, and the high-precision injection pump 3 is connected with the feeding head 8;

[0046] The focused ultrasonic transducer 4 includes 4 identical focused ultrasonic vibrators 401, all of which have a 90° fan-shaped structure, and form a complete circle with the wave-absorbing material 407 and have a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com