Marine equipment with self-repairing and underwater facility repairing functions and method

A marine equipment, self-repair technology, applied in the direction of transportation and packaging, ships, tracked vehicles, etc., can solve the problems of ocean-going equipment returning to the voyage for maintenance, untimely maintenance, and high maintenance costs, so as to improve operating efficiency, facilitate movement, and extend service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

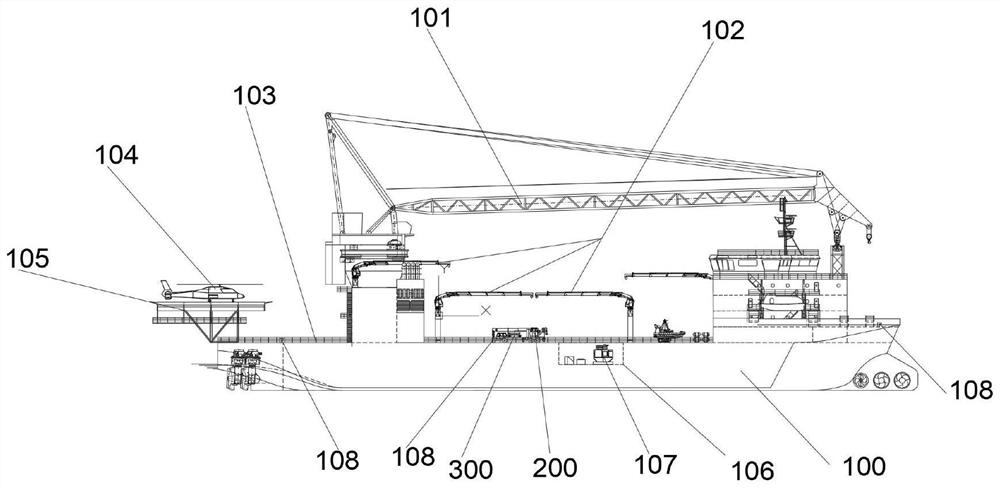

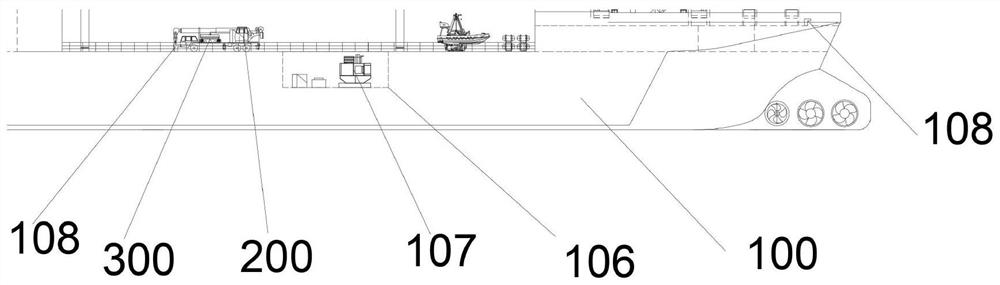

[0055] A kind of marine equipment with self-healing and underwater facility repairing functions, such as Figure 1-8 As shown, its repair function is completed by cooperation of the marine equipment main body 100, the self-repair vehicle 200, and the magnetic adsorption self-propelled repair robot 300. Among them: the marine equipment main body 100 provides energy for the self-repair vehicle 200 and the magnetic adsorption self-propelled repair robot 300 . The self-repair vehicle 200 is parked on the deck 103 of the marine equipment main body, and the magnetic adsorption self-propelled repair robot 300 is parked on the self-repair vehicle 100 . The self-repair vehicle 100 carries the magnetic adsorption self-propelled repair robot 300 to the damaged part of the marine equipment body 100 or the upper deck 103 corresponding to the underwater facility to be repaired, and releases the magnetic adsorption self-propelled repair robot 300 . The magnetic adsorption self-propelled rep...

Embodiment 2

[0076] The main body of marine equipment 100 that has served in the ocean for a long time, during the service process, the self-repair vehicle 200 cruises on the deck regularly, releases the magnetic adsorption self-propelled repair robot 300 to inspect the parts and structure of the marine engineering equipment 100, and searches for damaged parts. area and parts. Damaged areas are repaired using a combination of additive and subtractive manufacturing. If an irreparable part is found, the type of the part is recorded, and the parameters of the damaged part are sent to the part manufacturing cabin 106. The intelligent manufacturing equipment 107 in the part manufacturing cabin 106 remanufactures the damaged part, and replaces the damaged part after the manufacturing is completed. For underwater facilities that need to be repaired far away from the ocean equipment 100, the self-repair vehicle 200 releases the magnetic adsorption self-propelled repair robot 300 below the water su...

Embodiment 3

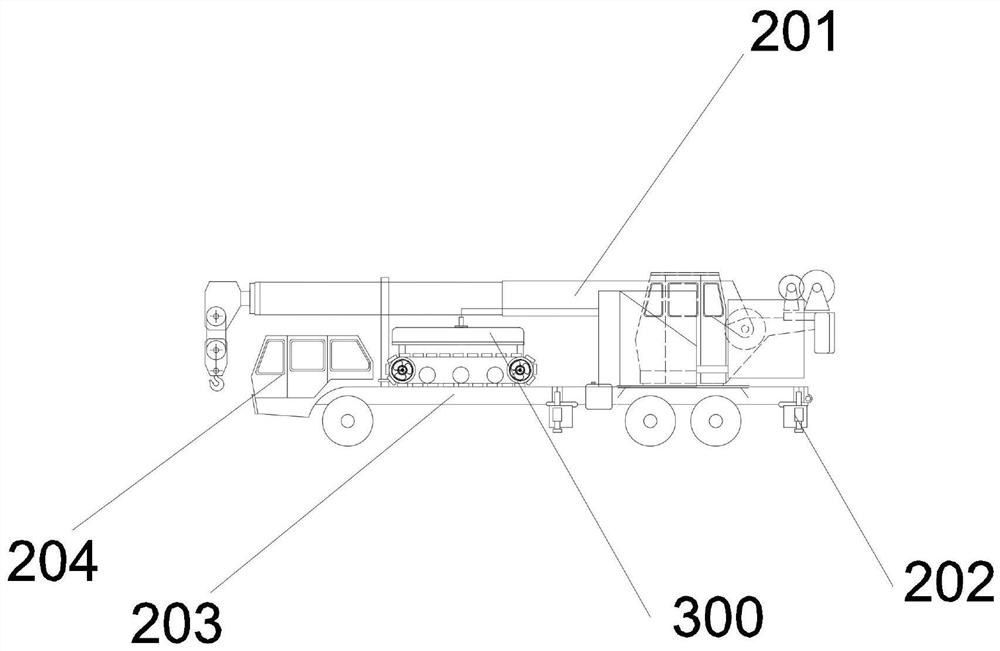

[0078] Such as Figure 7 As shown, the known damaged areas of the marine equipment main body 100 are three areas A, B, and C. The self-repairing vehicle 200 drives to the vicinity of the energy interface 108 above the A area by its own power, and the energy interface 108 is connected to the self-repairing vehicle 200 to provide energy for the self-repairing vehicle 200 . The self-repair vehicle 200 moves the magnetic adsorption type self-propelled repair robot 300 to the outboard of the marine equipment main body 100 through a small crane 201, and the magnetic adsorption type self-propelled repair robot 300 is attached to the bottom of the marine equipment main body 100 through a magnetic adsorption type crawler 304. On the outside, the magnetic adsorption type self-propelled repair robot 300 drives the magnetic adsorption type crawler 304 to rotate through the track driving wheel 308, so that the magnetic adsorption type self-propelled repair robot crawls along the outer side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com