Composite forming device of molten coating added and decreased materials

A composite forming and melt coating technology, applied in the field of 3D printing, can solve the problems of reducing forming efficiency, dimensional error and step effect, long time, etc., and achieve the effect of avoiding dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

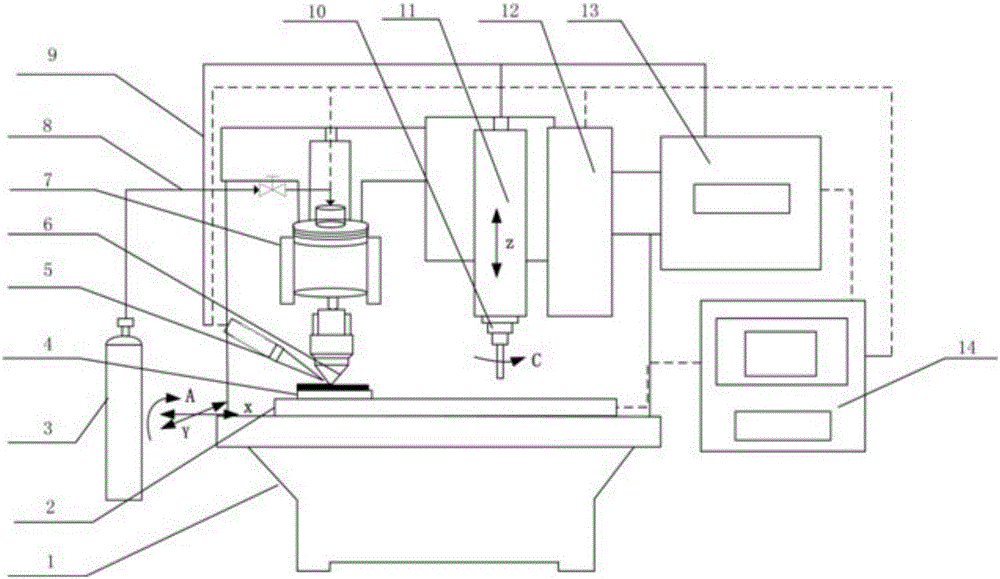

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

[0025] The invention provides a compound forming device for fusion coating increasing and decreasing materials, such as figure 1 As shown, it includes the coating additive forming part and the subtractive processing part arranged on the moving platform 2; wherein the moving platform 2 is arranged on the base 1, and the moving platform 2 can move or rotate in the horizontal direction.

[0026] Wherein the coated additive forming part includes an atmosphere protection device 3, and the atmosphere protection device 3 uses an inert gas, such as Ar or N 2 The atmosphere protection device 3 is connected to the top of the smelting device 7 through the connecting pipeline of the gas driving device 8. The gas driving device 8 also includes an air pressure valve, a pressure relief valve and a flow controller arranged on the connecting pipeline, and also includes a connecting pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com