Integrated forming additive manufacturing device and method of multi-material component

A technology of additive manufacturing and multi-material, applied in the field of additive manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

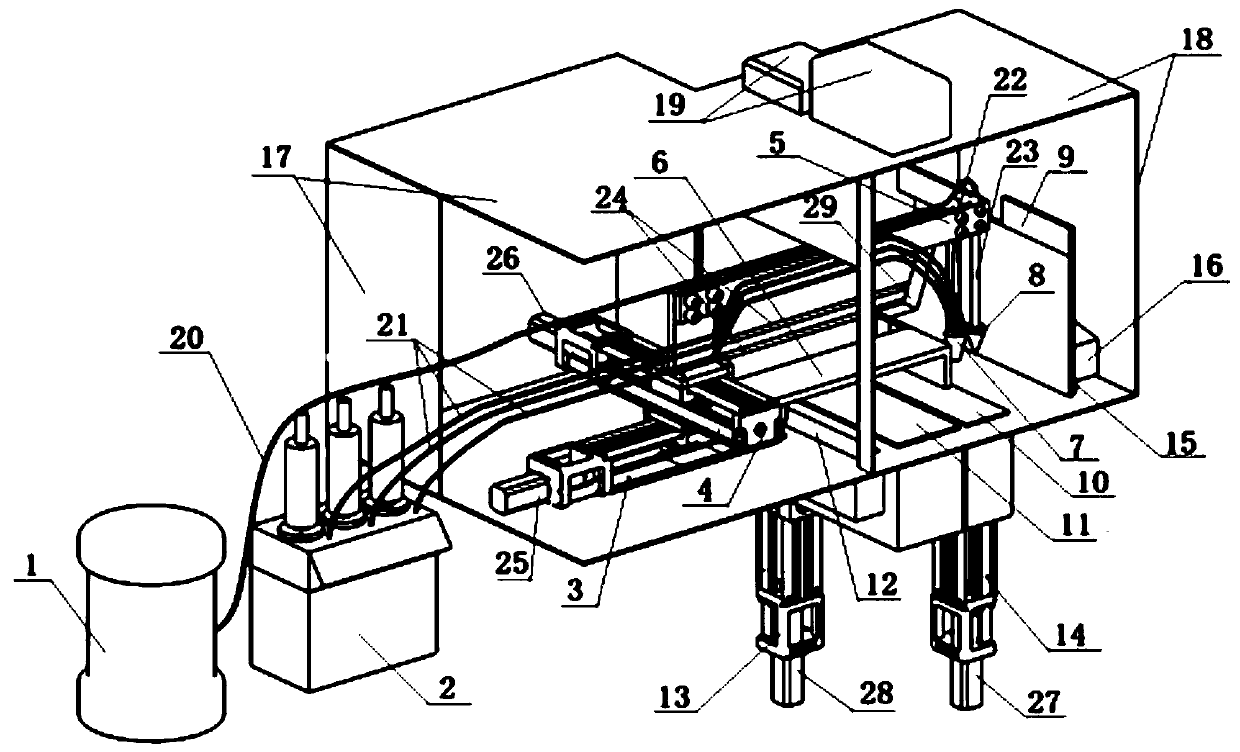

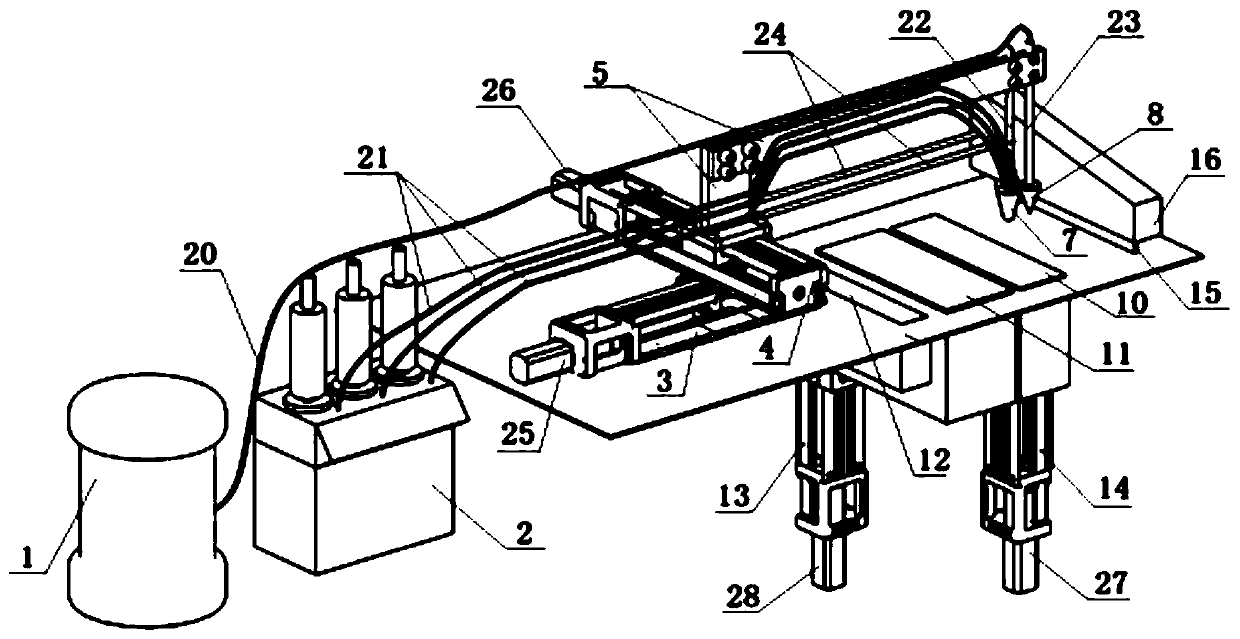

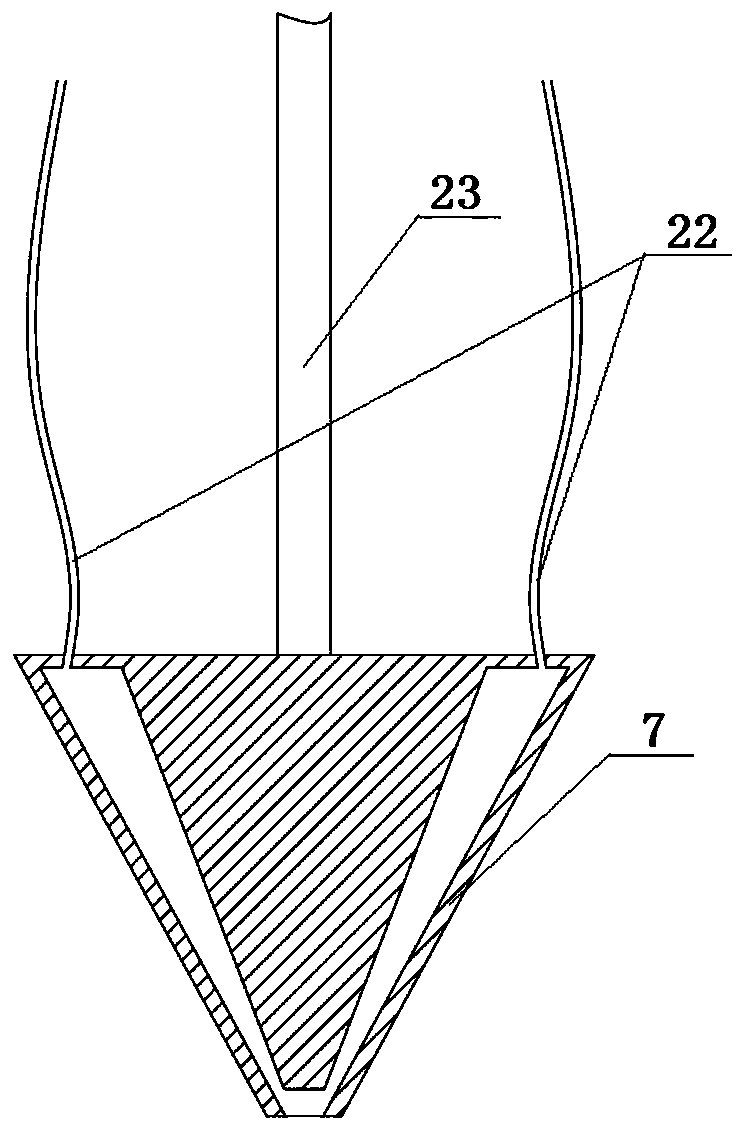

[0056] Such as Figure 1 to Figure 4 As shown, a multi-material component integrated forming additive manufacturing device, the forming device includes a powder feeding system, a forming cylinder 11, and the powder feeding system includes a powder flow feeder 2, a powder feeding pipeline 21 and a multi-channel The powder mixing nozzle 7, the powder feeding pipeline 21 is multiple, and the powder feeding pipeline 21 is used as a pipeline for the powder flow powder feeder 2 to transfer powder to the multi-channel powder mixing nozzle 7;

[0057] It also includes a powder cleaning system, which includes a vacuum cleaner 1, a powder cleaning pipeline 20 and a powder cleaning nozzle 8, and the powder cleaning pipeline 20 is used as a connecting pipeline between the vacuum cleaner 1 and the powder cleaning nozzle 8, so that When the vacuum cleaner 1 is working, a suction force is generated on the inlet end of the powder cleaning nozzle 8 to suck the powder on the powder feeding cyli...

Embodiment 2

[0066] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 4 As shown, in order to make this solution not only suitable for the integrated forming of multi-material components, but also adapt to the preparation of existing gradient function parts, the setting is: at the same time, the powder flow powder feeder 2 can pass through at least two powder feeding pipelines 21, and simultaneously feed multiple The multi-way powder mixing nozzle 7 conveys powders of different components; the multi-way powder mixing nozzle 7 is provided with a mixing chamber, and the powder from different powder feeding pipelines 21 passes through the multi-way powder mixing nozzle 7 through the mixing chamber, and the The powder mixing takes place in the mixing chamber or at the powder output end of the multi-way powder mixing nozzle 7 . Gradient function parts use two or more materials with different properties. By continuously changing the components of the ...

Embodiment 3

[0081] On the basis of any one of the technical solutions provided in Embodiment 1 or 2, this embodiment discloses a multi-material component integrated forming additive manufacturing method, including a powder spreading step. The required powder is laid on the forming cylinder 11, and the powder spreading step includes a local powder replacement process on the working surface of the forming cylinder 11, and the replacement process is realized by any one of the manufacturing devices provided above: including the powder cleaning step and powder replenishment steps;

[0082] The powder cleaning step is: under the action of the driving mechanism, by changing the position of the powder cleaning nozzle 8 in the space, using the powder cleaning nozzle 8 to complete the powder removal of the powder in the selected area of the working surface of the forming cylinder 11, and obtain a powder removal area;

[0083] The powder replenishment step is to replenish powder into the powder r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com