A method for building a metallurgical furnace and its 3D printing robot

A 3D printing, metallurgical furnace technology, applied in the field of aluminum electrolysis, to avoid waste, stable performance, and protect the physical and mental health of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

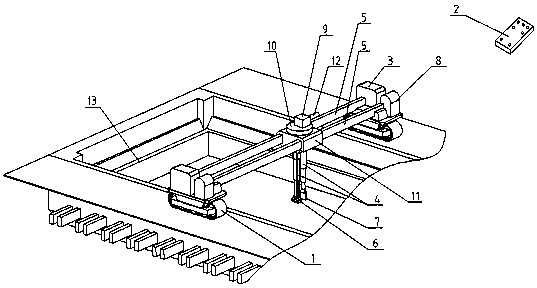

[0020] Such as figure 1 Shown, when the present invention is used for metallurgical kiln 13, implement like this:

[0021] Before building the furnace, the trolley 1 walks on the rails set on both sides of the metallurgical furnace 13, and the control system 8 drives the 3D scanner in the actuator 3 to scan the furnace in three dimensions, analyze and process the scanned data, and carry out reverse construction. Then the actuator 3 compares the modeling results with the design of the furnace, determines the area where furnace materials are added, and makes a printing plan.

[0022] When building a furnace, the positioning sensor 5 installed on the multi-dimensional motion robot arm 4 moves along with the robot arm along three dimensions in the furnace for initial positioning, and then the robot arm automatically selects a furnace building tool from the tool holder according to the printing plan 6 If the furnace hammer head is to be built, move it to the position to be built; ...

Embodiment 2

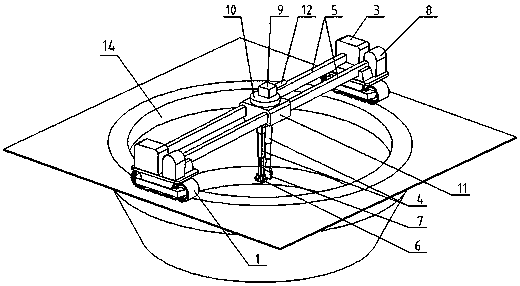

[0026] Such as figure 2 Shown, when the present invention is used for yellow phosphorus stove 14, implement like this:

[0027] Before the furnace is built, the walking trolley 1 walks on the track set in the circular direction of the yellow phosphorus furnace 14, and the control system 8 drives the 3D scanner in the actuator 3 to scan the furnace in three dimensions, analyze and process the scanned data, and carry out reverse construction. Then the actuator 3 compares the modeling results with the design of the furnace, determines the area where furnace materials are added, and makes a printing plan.

[0028] When building a furnace, the positioning sensor 5 installed on the multi-dimensional motion robot arm 4 moves along with the robot arm along three dimensions in the furnace for initial positioning, and then the robot arm automatically selects a furnace building tool from the tool holder according to the printing plan 6 If the furnace hammer head is to be built, move it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com