Beneficiation method for producing quartz and feldspar by using river and lake sands

A beneficiation method and feldspar technology, which are applied in flotation, solid separation and other directions, can solve the problems of inability to separate quartz and feldspar, and achieve the effects of reducing depletion, reducing costs and protecting the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

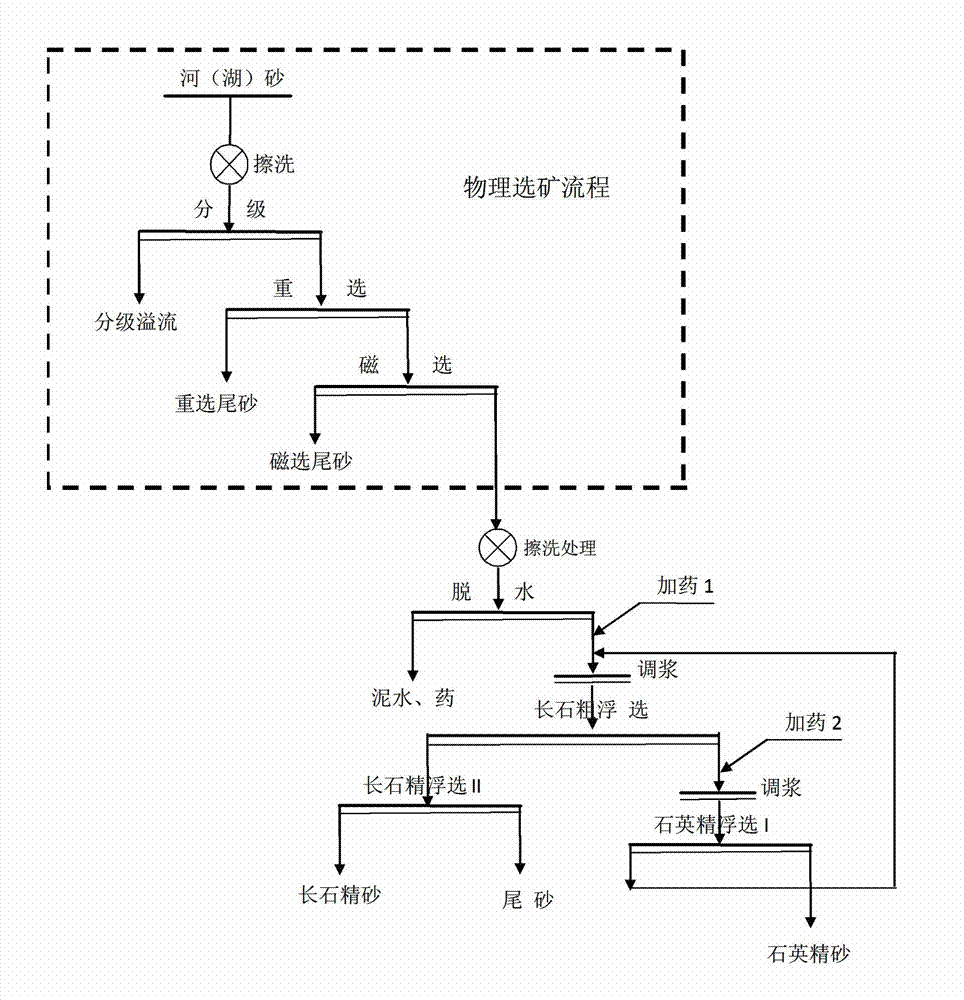

[0016] Table 1 is two embodiments of the present invention, all according to figure 1 The process shown is for beneficiation, and the implementation conditions are as follows:

[0017] Scrubbing: scrubbing concentration: 50%, scrubbing time: 30min

[0018] Surface pretreatment: H 2 SO 4 : 1.75kg / t, HF: 0.25kg / t, concentration: 50%, time: 20min

[0019] Coarse flotation (selection): ammonium salt flotation collector: 3.0kg / t, PH: 2.5

[0020] Quartz fine (flotation) separation: amine salt and petroleum sulfonate mixed anion and cation collector: 3.0kg / t, PH: 2.5

[0021] Feldspar fine (flotation) separation: ammonium salt flotation collector: 2.0kg / t, PH: 2.5

[0022] Implementation Case Results Table 1

[0023]

[0024] The results show that the chemical indexes of the quartz concentrate and feldspar concentrate after the above process meet the requirements of the glass and ceramic industries, and have broad application prospects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com