Quick fired fine ceramics made in open flame roller hearth kiln and technical method

A technology of fine ceramics and roller kiln, which is applied in applications, household utensils, clay products, etc. It can solve the problems of unrefined glaze texture, poor glaze gloss, and poor impact strength, so as to achieve reasonable glaze formula, Short firing cycle and high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

10.3

0.8

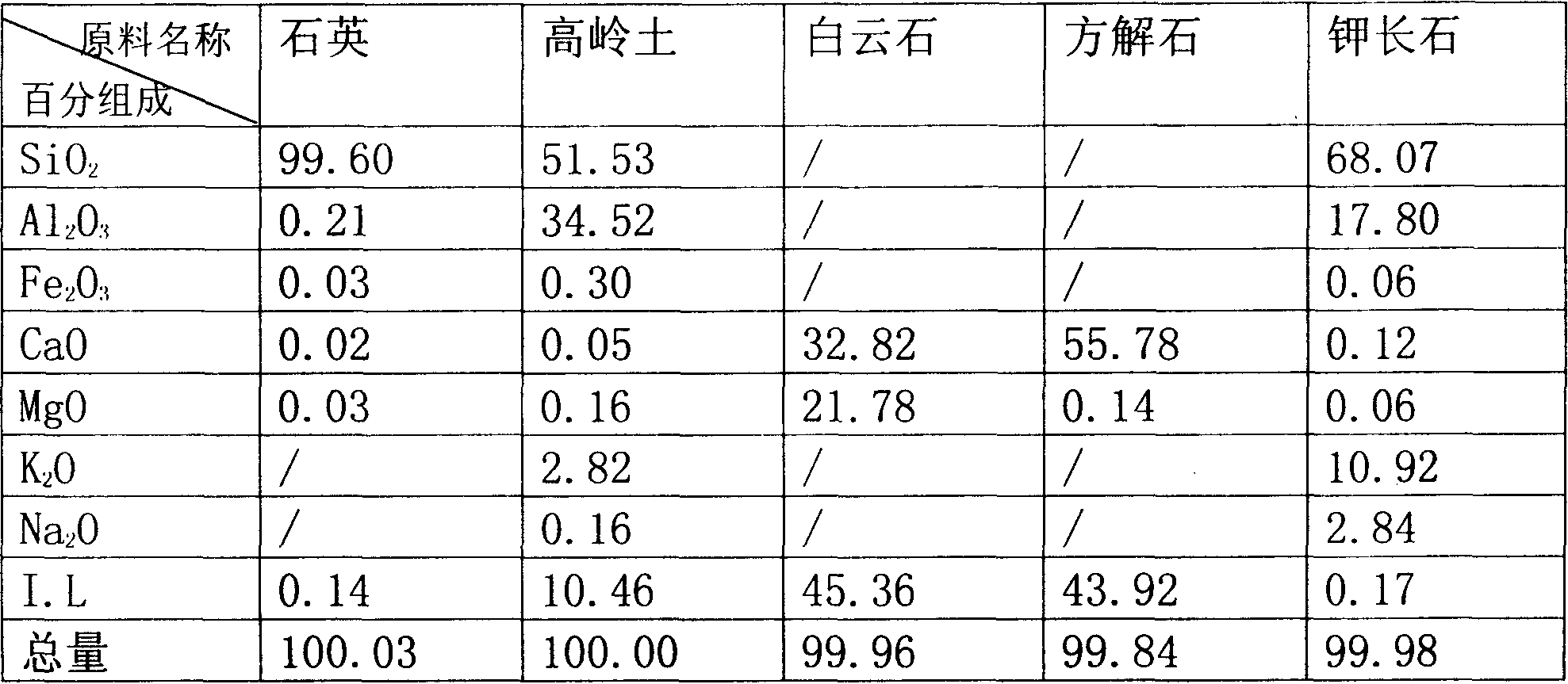

[0048] 4) Raw material percentage composition (%)

[0049]

[0050] The invention makes full use of the excellent characteristics of quartz to solve the formulation of blank glaze and open flame firing process. First: Use domestic best-quality quartz (purity greater than 99.6%, particle size 200 mesh, well-crystallized vein quartz), with a whiteness of more than 90. Quartz becomes the skeleton of the green body at high temperature. Under reducing and oxidizing atmospheres After firing, the green body will appear beautiful tender white and elegant milky yellow. Second: According to the theoretical basis of the thermal expansion and phase change of quartz in the green body, during the firing process, the thermal expansion of quartz can partially offset the shrinkage of the green body, and form mullite together with alumina to prevent the green body softening deformation occurs. Third: Due to the high hardness of quartz, through the introduction o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com