FFC slurry for large-size products and preparation method thereof

A large-size, slurry technology, applied in the field of FFC slurry and its preparation of large-size products, can solve the problems of higher shrinkage rate and large size of slurry, so as to reduce shrinkage, improve the regularity of finished products, and whiteness of porcelain body high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

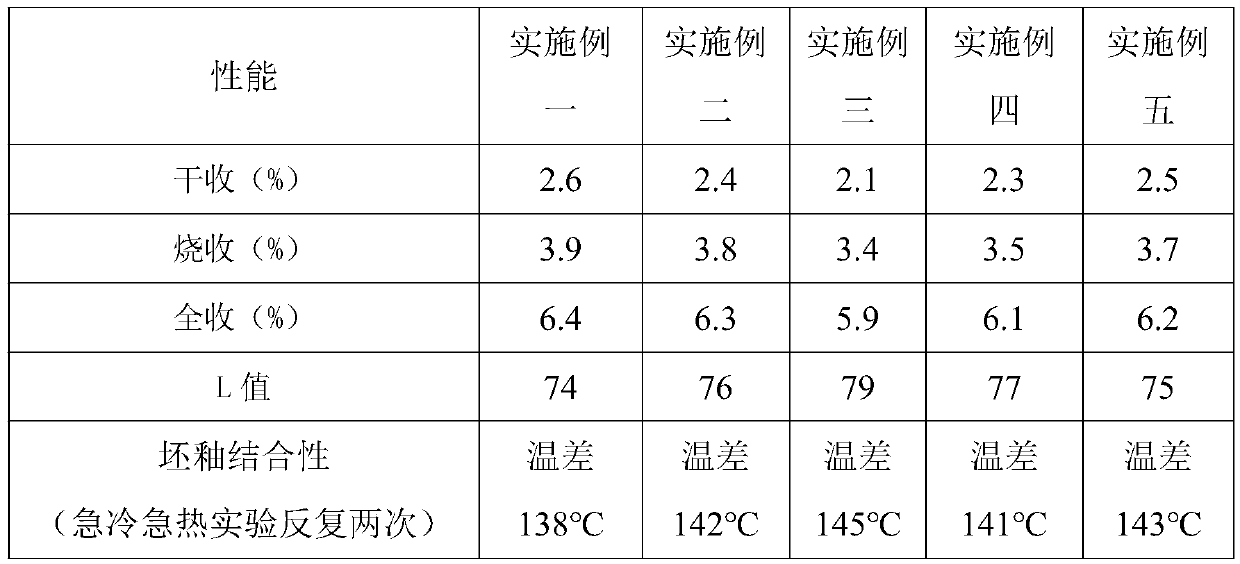

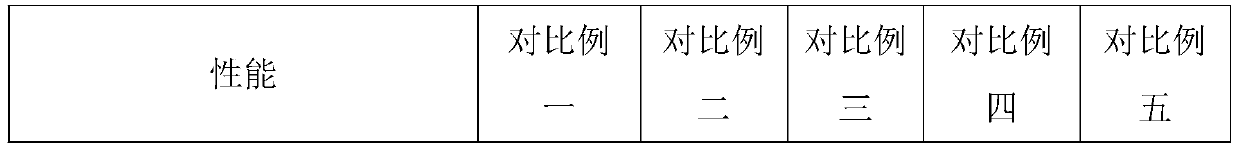

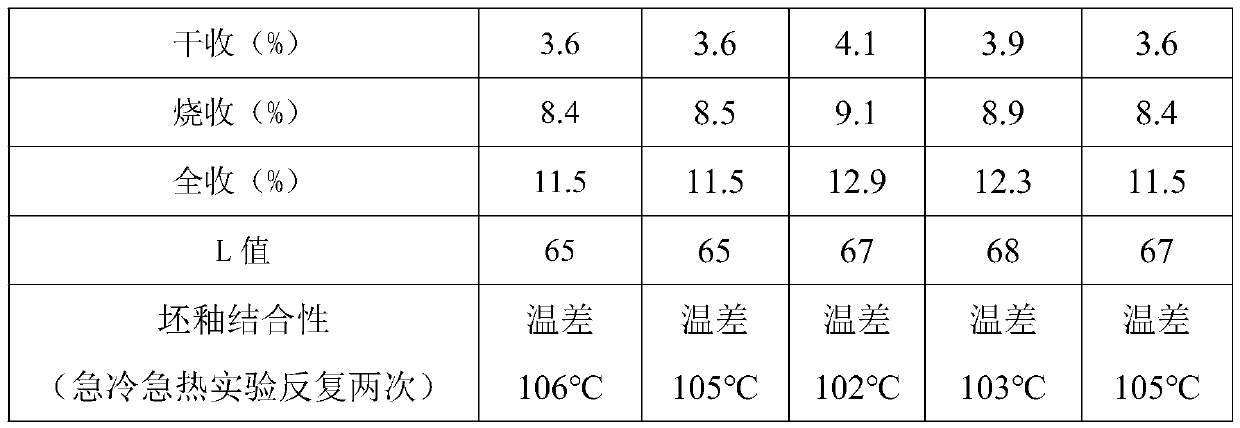

Examples

Embodiment 1

[0033] The invention discloses an FFC mud used for large-scale products. The raw materials include the following components in parts by weight: 15 parts of water glass, 44 parts of calcined coke gemstones with a calcination temperature of 1245 ° C, 8 parts of kaolin, and 8 parts of glass fiber powder , 16 parts of nano-silica sol, 34 parts of absolute ethanol, 8 parts of anti-dehydration cracking agent, and 47 parts of water.

[0034] in:

[0035] The dehydration cracking agent comprises the following components in parts by weight: 20 parts of 100-mesh lignin fiber, 8 parts of sodium hexametaphosphate, and 5 parts of 120-mesh expanded graphite.

[0036] The chemical composition of the dried mud body includes by weight percentage: 59% silicon dioxide, 30% aluminum oxide, 1% titanium dioxide, 0.4% iron oxide, 0.15% calcium oxide, 1.6% magnesium oxide, 0.35% potassium oxide, sodium oxide 2.5%, burning reduction: 5%.

Embodiment 2

[0038]A kind of FFC slurry for large-scale products, the raw materials include the following components by weight: 16 parts of water glass, 45 parts of calcined burnt gemstones with a calcination temperature of 1246 ° C, 10 parts of kaolin, 12 parts of glass fiber powder, and nano-silica sol 12 parts, 28 parts of absolute ethanol, 10 parts of anti-dehydration cracking agent, 50 parts of water.

[0039] in:

[0040] The dehydration cracking agent comprises the following components by weight: 22 parts of 103-mesh lignin fiber, 6 parts of sodium hexametaphosphate, and 3 parts of 123-mesh expanded graphite.

[0041] The chemical composition of the dried mud body includes by weight percentage: 60% silicon dioxide, 30.5% aluminum oxide, 1.16% titanium dioxide, 0.51% iron oxide, 0.21% calcium oxide, 1.62% magnesium oxide, 0.39% potassium oxide, sodium oxide 1.01%, burning reduction: 4.6%.

Embodiment 3

[0043] A kind of FFC slurry for large-scale products, the raw materials include the following components by weight: 17 parts of water glass, 46 parts of calcined burnt gemstones with a calcination temperature of 1250 ° C, 12 parts of kaolin, 12 parts of glass fiber powder, and nano-silica sol 13 parts, 30 parts of absolute ethanol, 13 parts of anti-dehydration cracking agent, 54 parts of water.

[0044] in:

[0045] The dehydration cracking agent comprises the following components in parts by weight: 30 parts of 110-mesh lignin fiber, 11 parts of sodium hexametaphosphate, and 5 parts of 125-mesh expanded graphite.

[0046] The chemical composition of the dried mud body includes by weight percentage: 60.3% of silicon dioxide, 30.5% of aluminum oxide, 1.14% of titanium dioxide, 0.44% of iron oxide, 0.21% of calcium oxide, 1.68% of magnesium oxide, 0.42% of potassium oxide, sodium oxide 1.21%, burning reduction: 4.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com