Light-emitting diode (LED) lamp heat dispersing material and preparation method thereof as well as radiator and LED lamp

A technology of LED lamps and heat dissipation materials, applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., can solve problems such as difficulty in meeting flatness requirements, easy to produce deformation, etc., and achieve good heat dissipation effect. Easy to deform, high heat radiation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

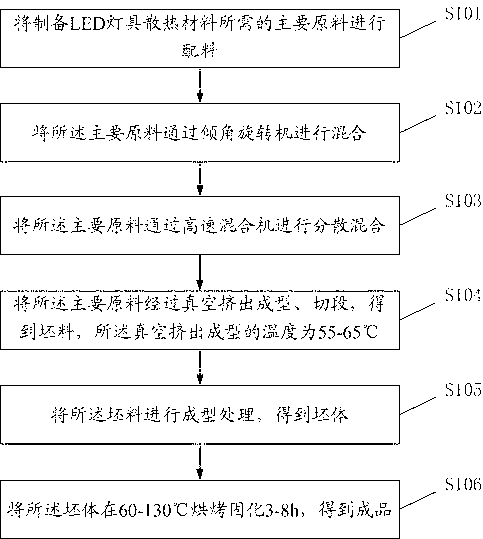

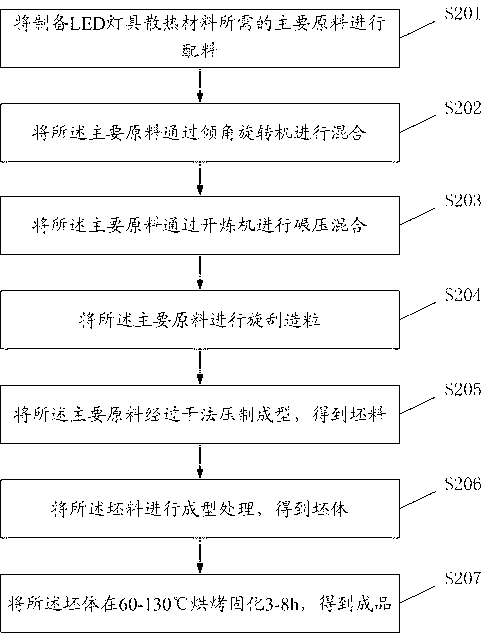

[0105] Accordingly, see figure 1 , the present invention provides a first embodiment of a method for preparing heat dissipation materials for LED lamps. The preparation method mainly adopts an extrusion molding method, which sequentially includes the following steps:

[0106] S101, batching main raw materials required for preparing heat dissipation materials for LED lamps.

[0107] Wherein, the formula of the main raw material in percent by volume is as follows:

[0108] Epoxy resin 15-27%

[0109] Ceramic powder filler 73-85%;

[0110] Described epoxy resin selects the epoxy resin of epoxy value 0.38-0.54mol / 100g for use;

[0111] The ceramic powder filler is selected from one or more of mullite-corundum, mullite, and silica glass phases, and the mullite-corundum, mullite, and silica glass phases are ceramic fired The waste is obtained through pretreatment.

[0112] Preferably, in the preparation of the heat dissipation material for LED lamps by extrusion molding, the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com