Self-forming glaze white jade porcelain pug and manufacturing method of porcelain pug product

A manufacturing method and self-glazing technology, applied in the field of ceramic manufacturing, can solve the problems of complex production process, large proportion of kaolin, high manufacturing cost, etc., and achieve the effect of reducing energy consumption, reducing carbon emissions, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

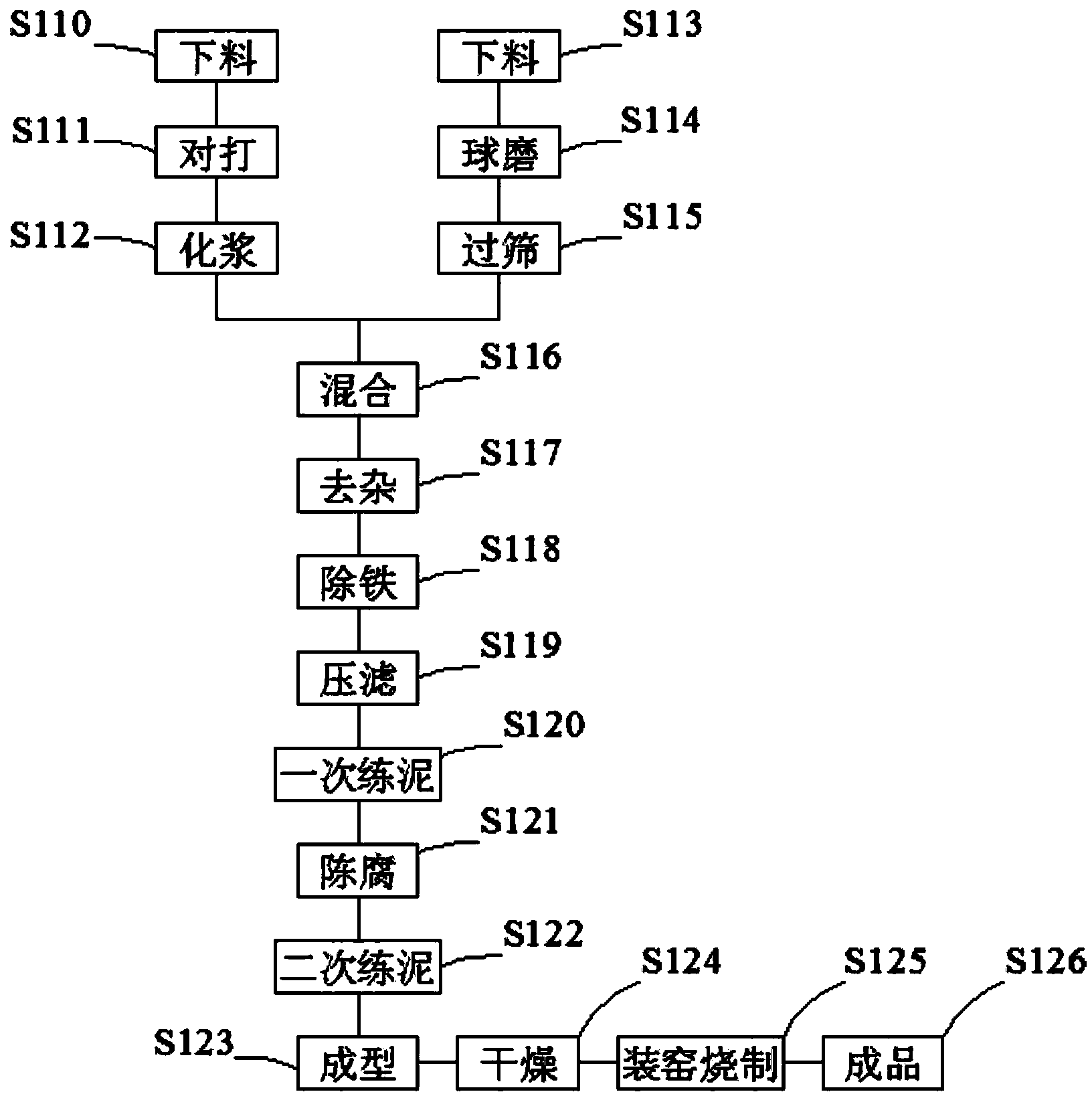

[0037] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0038] The invention provides self-glazed white jade porcelain mud, the porcelain mud formula is: kaolin 13-21%, feldspar 14-20%, bentonite 2-7%, quartz 38-47%, wollastonite 11-16%, Calcine 7-11%.

[0039] The present invention also provides a method for manufacturing porcelain clay products using the above-mentioned self-glazed white jade porcelain clay, the manufacturing method comprising the following steps:

[0040] S110: blanking, choose soft material kaolin 140kg;

[0041] S111: sparring, putting the kaolin into a concave-convex mold equipped with wooden sticks and sparring, so that the kaolin is broken and the particle size becomes smaller; the diameter of the wooden sticks of the concave-convex mold equipped with wooden sticks is 25-45 cm , the time when the kaolin is put into the concave-convex mold equipped with wooden ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com