Equipment for preparing ceramic powder by humidifying dry powder

A ceramic powder and equipment technology, applied in the field of production and processing equipment, can solve the problems of high energy consumption cost, unstable particle size gradation, failure to meet the requirements of ceramic production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

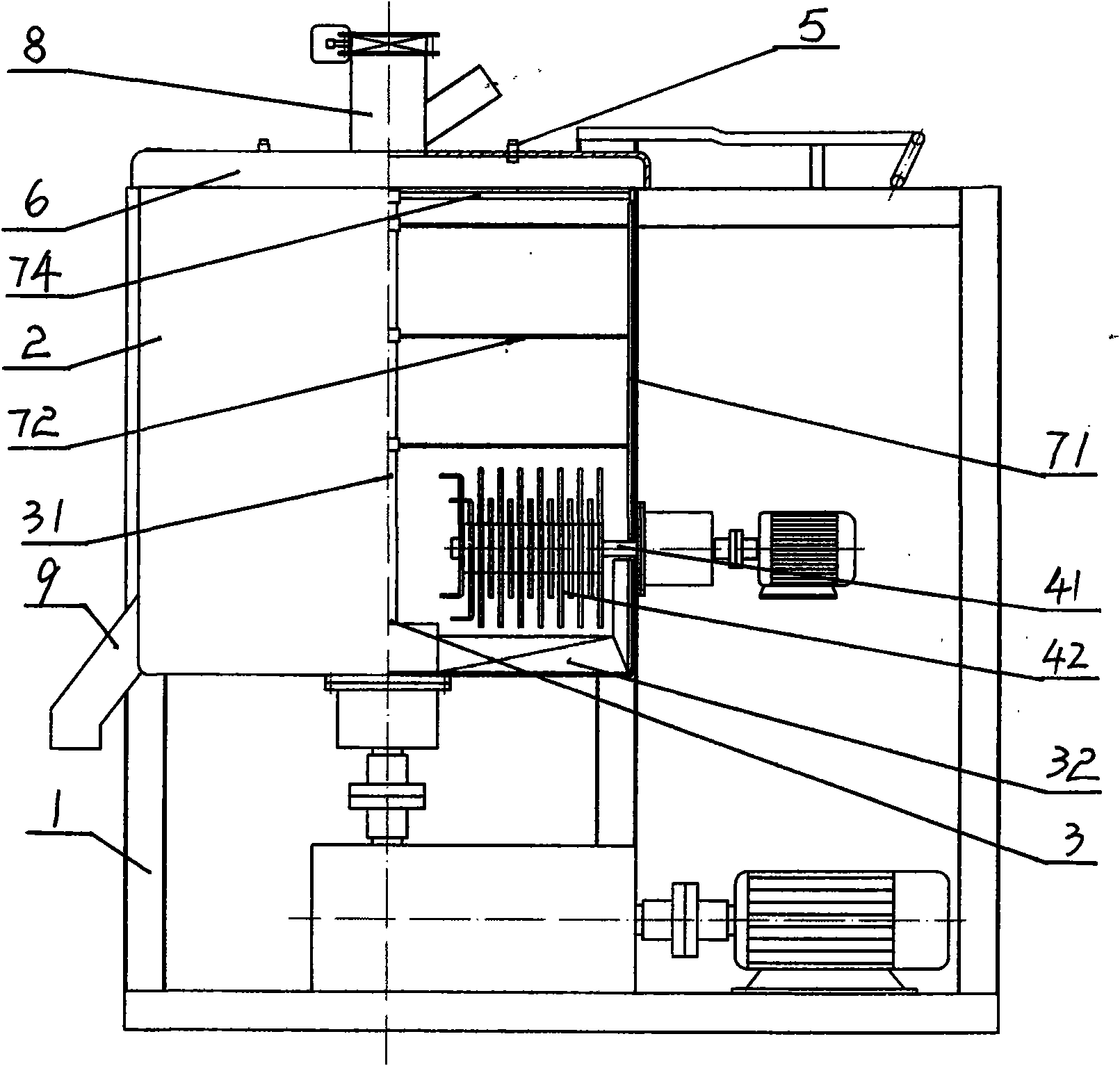

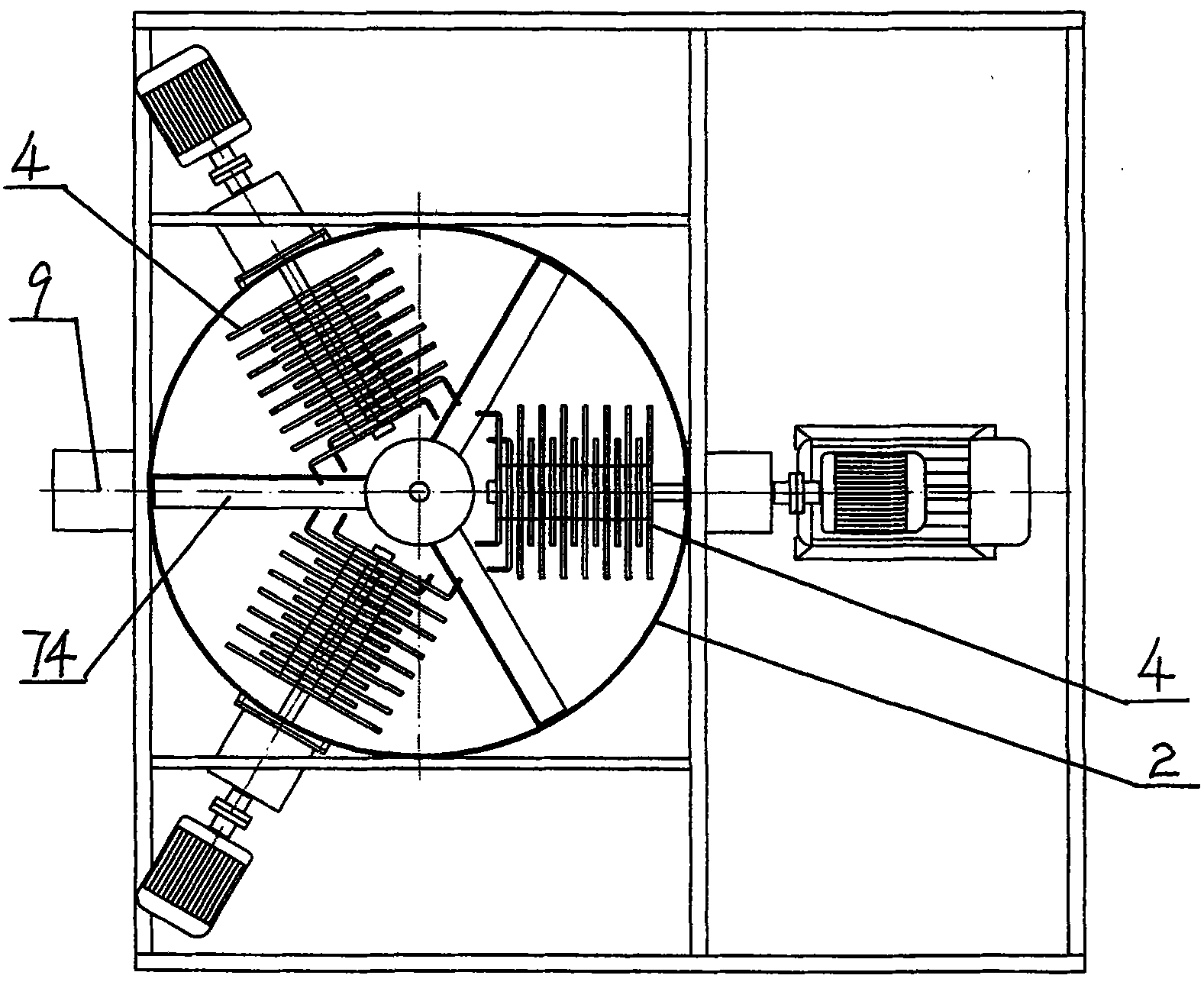

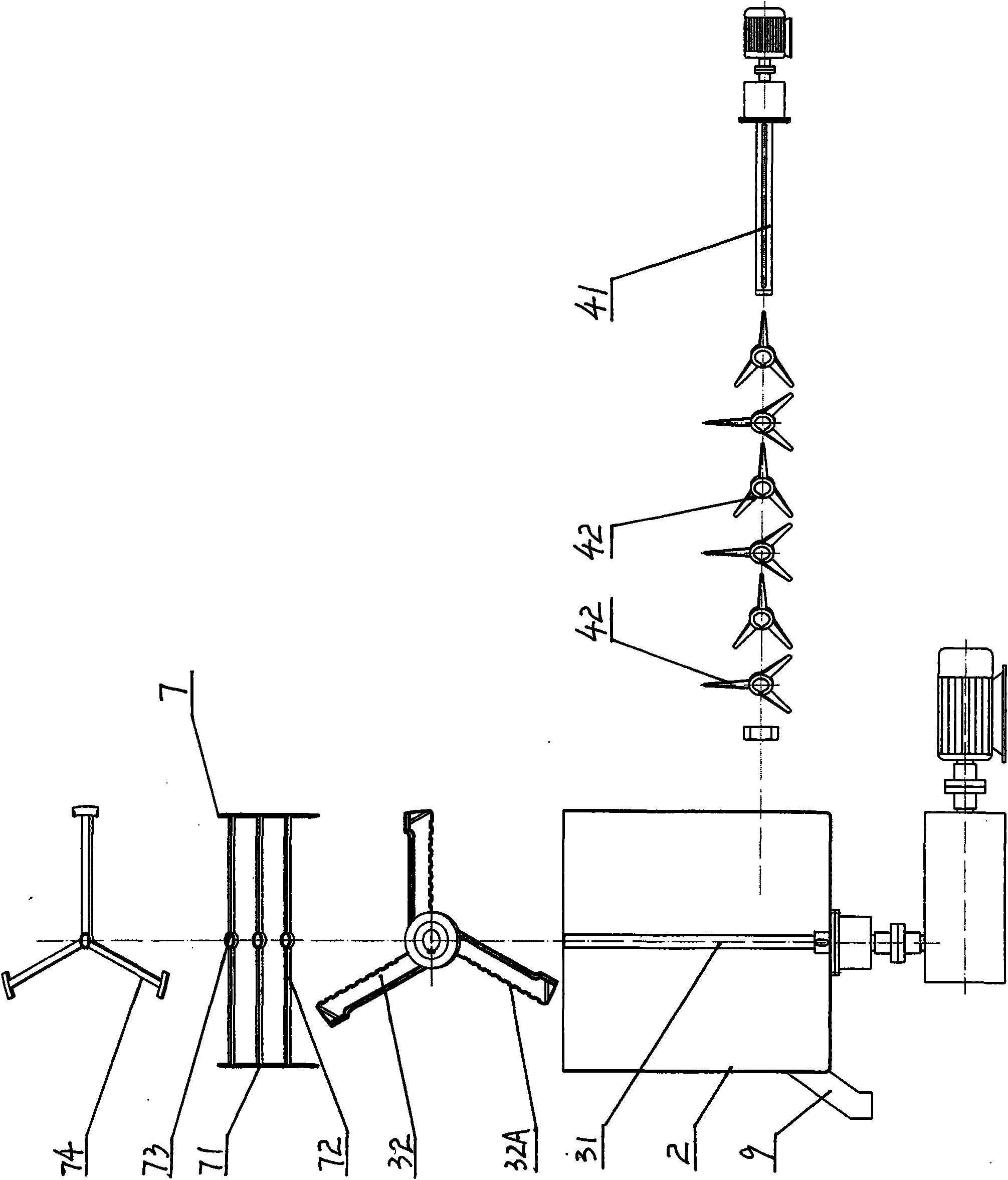

[0017] Embodiment one, see Figure 1-5 , This embodiment is mainly composed of a frame 1, a granulation tank 2, a stirring mechanism 3, a cutting mechanism 4, a scraping mechanism 7, an inlet 8, an outlet 9, and a power mechanism. The cylindrical granulation tank 2 is arranged on the frame 1; the sealing cover 6 at the top of the granulation tank 2 is provided with an atomizing water supply nozzle 5 and a feed port 8; the stirring mechanism 3 is arranged at the bottom of the granulation tank 2, and The stirring shaft 31 and the stirring paddle 32 are composed of the stirring paddle 32, which is a multi-blade structure. The plane of the paddle and the stirring shaft 31 form a 75-degree inclination angle. There are three paddles. Turning, mixing, granulating. One side edge 32A of its rotating direction of the paddle of stirring paddle 32 is tooth shape, and the tooth shape between each paddle is misplaced and arranged (as Figure 8 shown). The cutting mechanism 4 is arranged ...

Embodiment 2

[0020] Embodiment 2. The structure of this embodiment is basically similar to that of Embodiment 1. It also consists of a frame 1, a granulation tank 2, a stirring mechanism 3, a cutting mechanism 4, a scraping mechanism 7, an atomizing water supply nozzle, a sealing cover, and a row Composed of air port, material inlet, material outlet and power mechanism. The main difference is that the paddle plane of the stirring paddle forms an inclination angle of 65 degrees with the stirring main shaft, and there are five paddle blades. Four sets of cutting mechanisms 4 are arranged symmetrically in the granulation tank 2, and each set of cutting mechanisms has four cutting blades 43 fastened to them. On the cutting main shaft; the cutting blade 43 is a three-bladed knife, and its blade all has a cutting edge 43A, and the blade end is upwardly bent at 90 degrees (as Figure 6 , Figure 7 ), the cutting blades 43 are equally staggered and superimposed on the cutting main shaft; . In o...

Embodiment 3

[0021]Embodiment 3, the structure of this embodiment is basically similar to that of Embodiment 1, and it is also composed of a frame 1, a granulation tank 2, a stirring mechanism 3, a cutting mechanism 4, a scraping mechanism 7, an atomizing water supply nozzle, a sealing cover, and a row Composed of air port, material inlet, material outlet and power mechanism. The main difference is that the paddle plane of the stirring paddle is at an angle of 55 degrees to the stirring spindle, and there are six paddles, and six sets of cutting mechanisms are set in the granulation tank, and each set of cutting mechanisms has eight cutting blades fastened to the cutting spindle The upper composition; the cutting blade is a single-blade knife with a hook at the end of the blade, and the cutting blades are staggered and superimposed on the main shaft; The length is one-third of the radius of the granulation tank; the cutting blade is driven to rotate by the cutting spindle to realize the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com