Composite needled filter felt

A filter felt and compound needle technology, applied in the fields of filtration and separation, synthetic resin layered products, layered products, etc., can solve the problems of unsuitable industrial and mining conditions, low temperature resistance, shortened service life, etc., to reduce the risk of chemical corrosion , The effect of high breaking strength in warp and weft direction and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

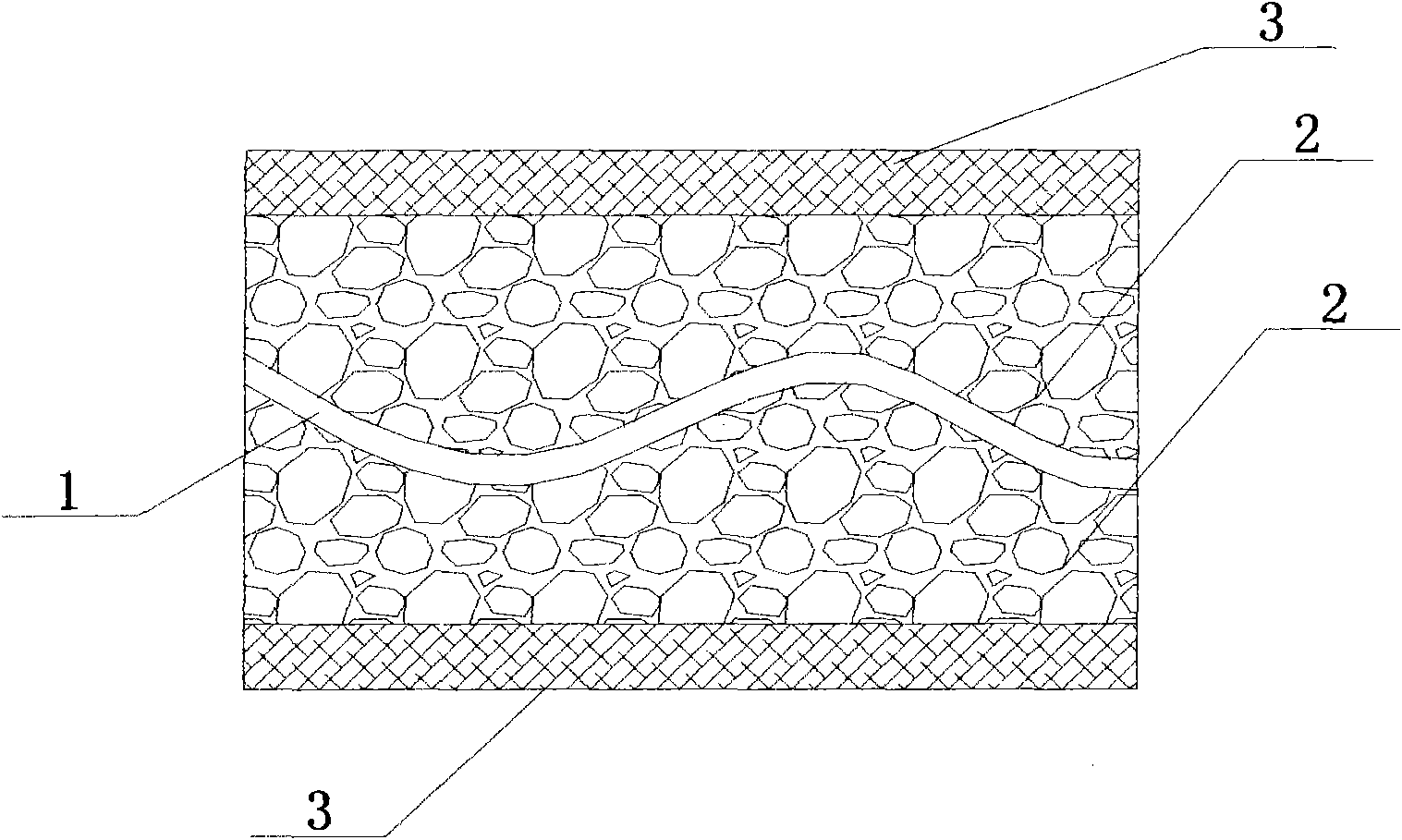

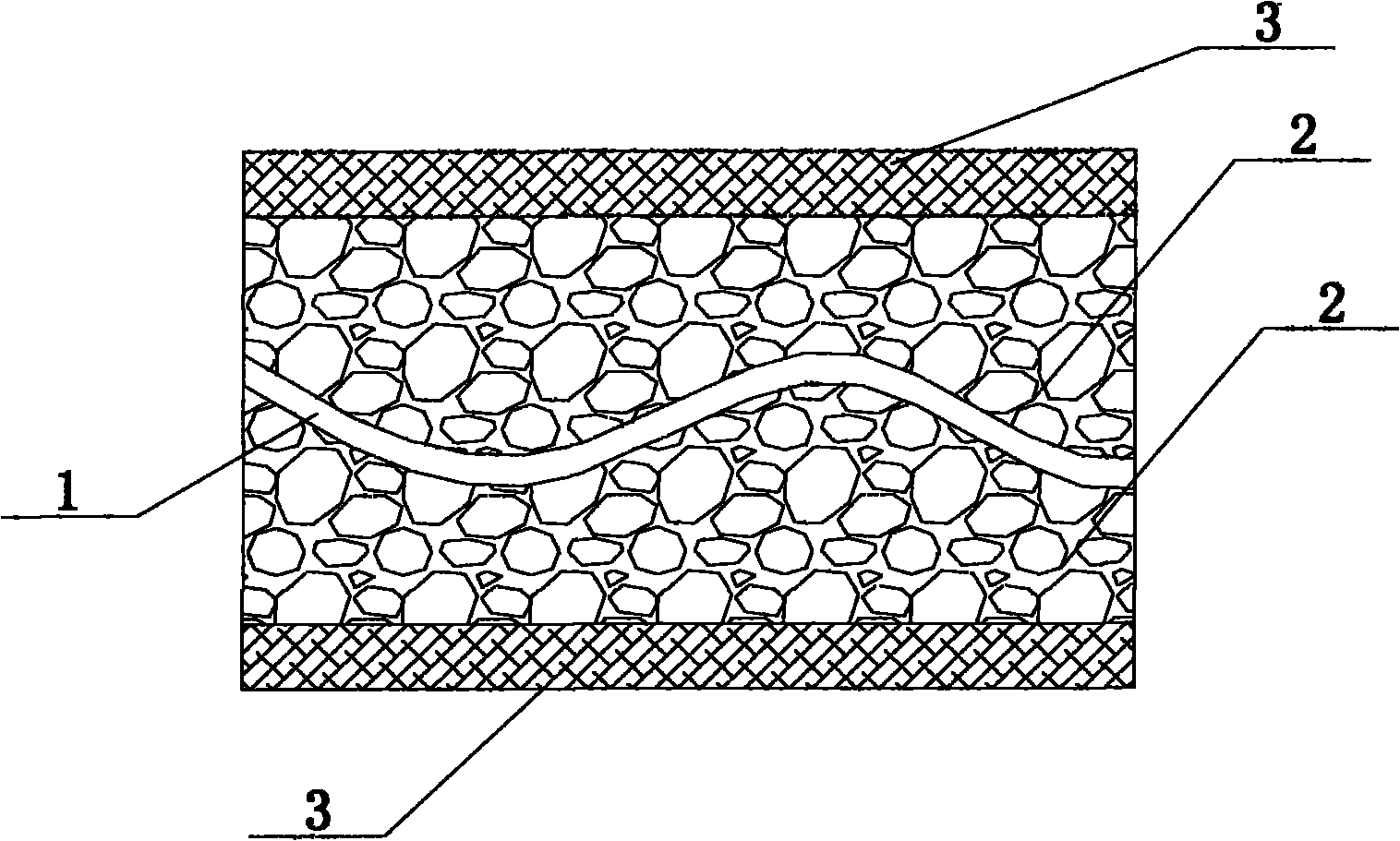

[0011] refer to Figure 1-2 , the specific embodiment adopts the following technical scheme: it is composed of glass fiber base cloth layer 1, polyester and polypropylene fiber composite layer 2 and PTFE impregnated coating layer 3, and the outer layer of glass fiber base cloth layer 1 is provided with polyester and polypropylene fiber Composite layer 2, polyester and polypropylene fiber composite layer 2 is covered with PTFE impregnated coating layer 3; its process route is: polyester, polypropylene fiber --> opening --> carding --> netting --> glass fiber Base fabric—>polyester, polypropylene fiber—>opening—>carding—>netting—>pre-needling—>main needling—>singeing—>calendering—>impregnation— —> finished product.

[0012] The impregnation is treated by PTFE impregnation method. The polyester and polypropylene fibers are fully mixed and the glass fiber is used as the base cloth, and then the glass fiber base cloth, polyester, and polypropylene fiber surface layer are completel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com