Fluorescent glaze and preparation method thereof

A glaze and fluorescent technology, applied in the field of building sanitary ceramic decoration, can solve the problems of complex process and rising cost, and achieve the effect of simple process and high fluorescent brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Weigh raw materials by weight percentage: 27.7% albite, 7.7% calcium carbonate, 5.8% barium carbonate, 1.8% zinc oxide, 0.4% aluminum oxide, 3.3% borax, 8.8% boric acid, 36.5% quartz, 5.0 % strontium carbonate, 1.5% vanadium pentoxide, and 1.5% bismuth oxide are mixed and melted at a temperature of 1250°C to 1350°C, and then water quenched to form a glass frit, and the glass frit is then coarsely crushed, finely crushed, The ingredients are ground, and the fineness of the ground glass frit powder is less than 0.2% after passing through a 300-mesh sieve;

[0023] (2) Weighing by weight percentage: 60% of glass frit powder, 32% of albite feldspar, 8% of calcined kaolin, mixed and ground by a ball mill to obtain a powder whose fineness is less than 2% of the residue on a million-hole sieve Fluorescent glaze.

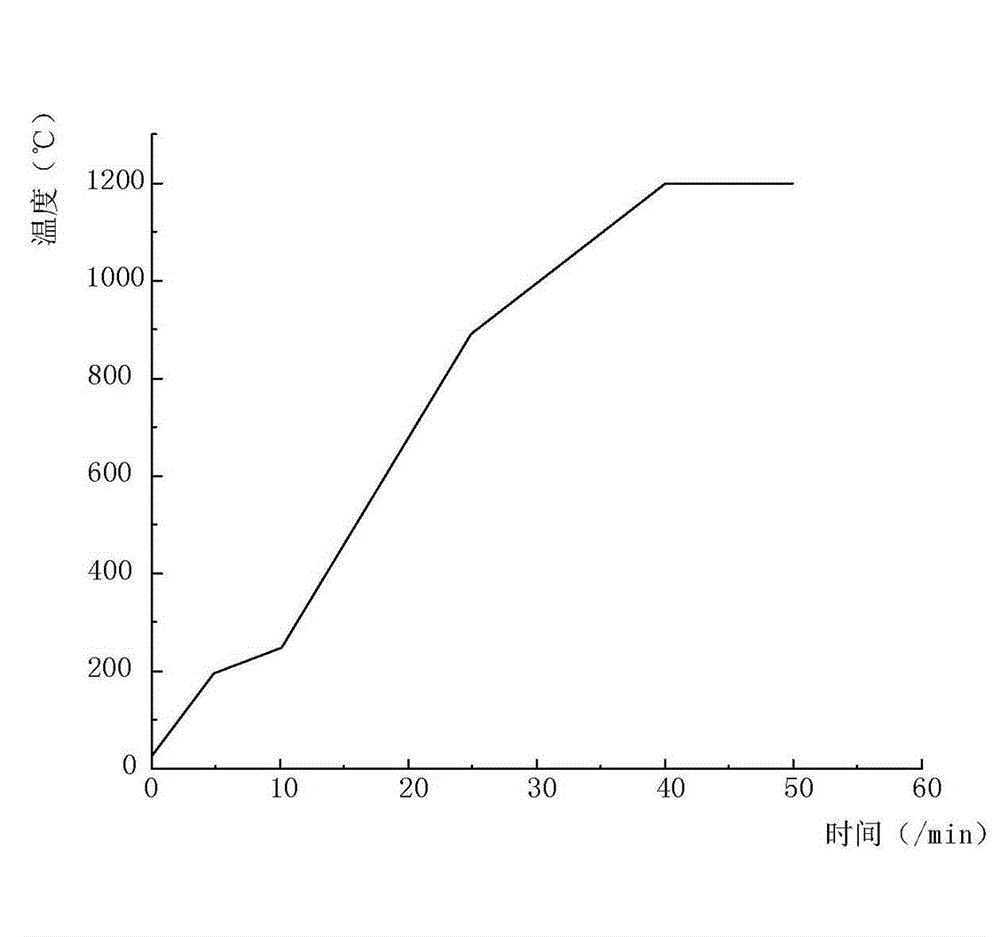

[0024] In the process of glazing, the optimum thickness of glazing is 0.5mm; it is confirmed by comprehensive experiments that the optimal firing temperature cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com