Method for synthesizing porous cordierite-mullite composite material by utilizing solid wastes

A technology for solid waste and cordierite, which is used in the removal of solid waste, furniture waste recycling, recycling technology, etc., to achieve uniform microscopic morphology, solve pollution, and improve high-temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Coal gangue, used magnesia-carbon bricks, and used sliding bricks are used as raw materials, and wood chips are used as pore-forming agents. The ratios are shown in Table 1. Composite materials were synthesized at 1340°C-1460°C under normal pressure for 2-6 hours. X-ray diffraction analysis and SEM fracture analysis were performed on the synthesized samples.

[0018] Table 1 Raw material ratio and synthesis conditions for the synthesis of porous cordierite-mullite composite materials

[0019]

[0020] 8

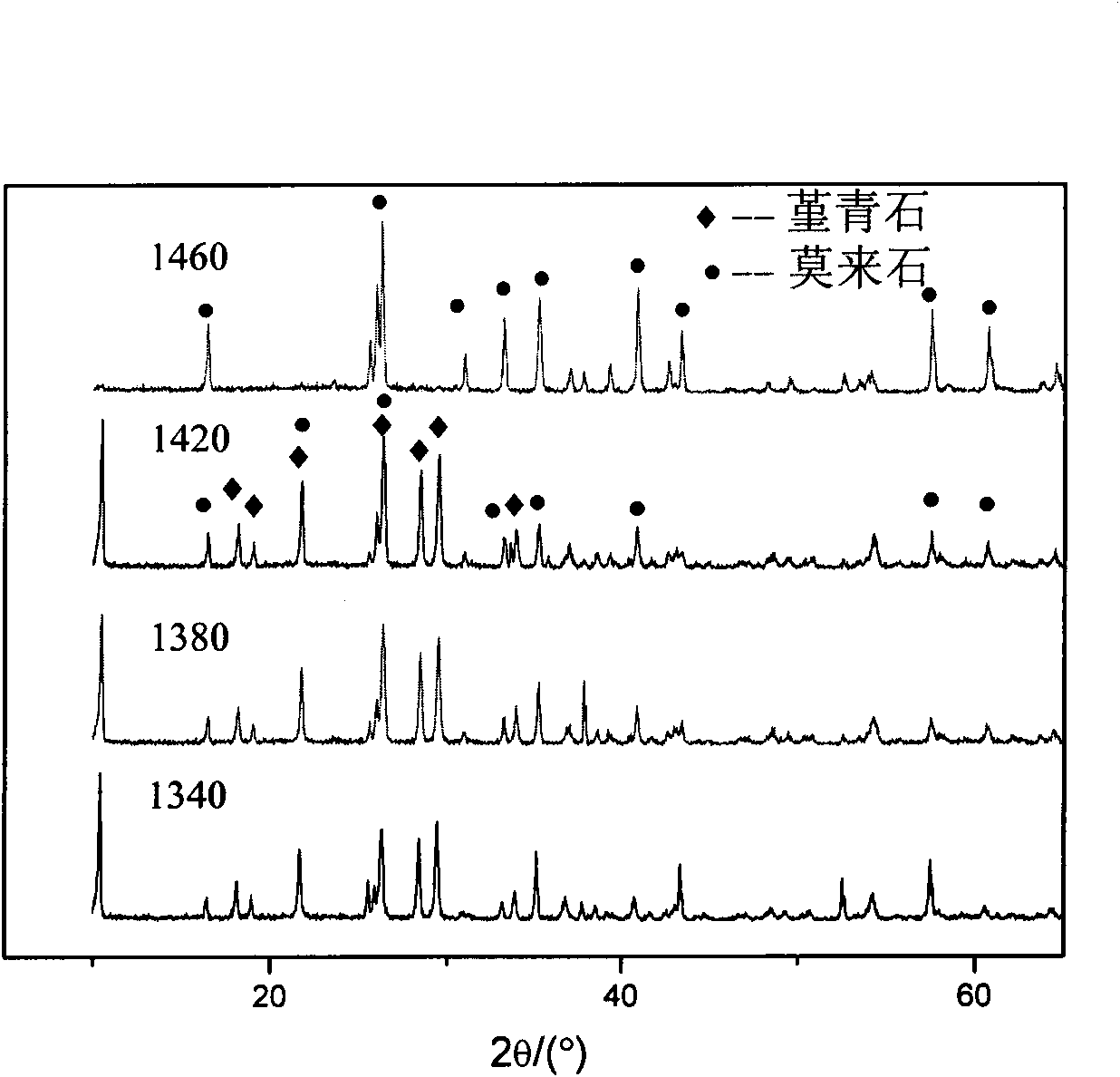

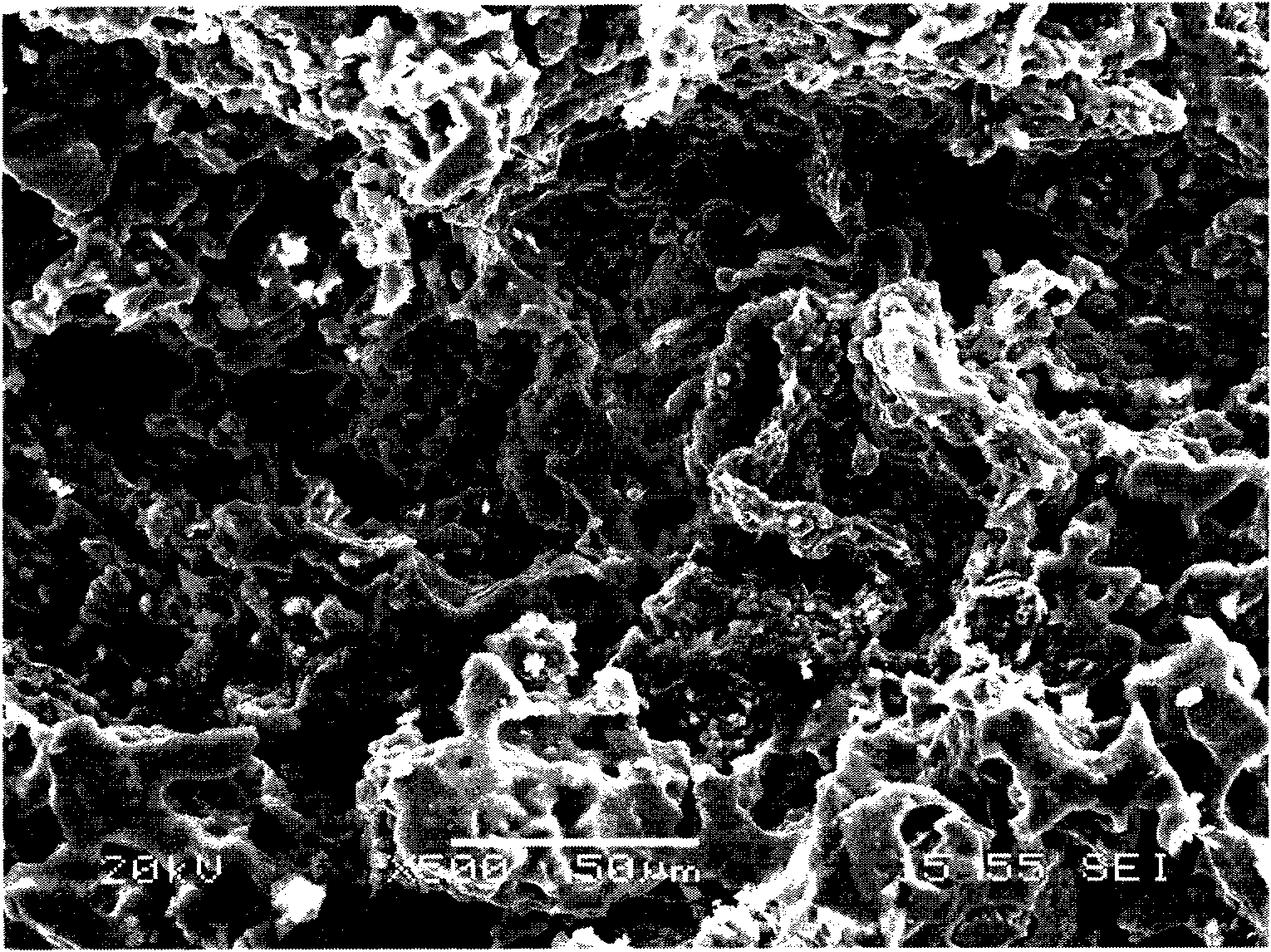

[0021] Porous cordierite-mullite composite materials with different porosity were obtained through experiments, and the X-ray diffraction results of cordierite (50%)-mullite (50%) synthetic materials at different temperatures were designed according to theory figure 1 It can be seen from the figure that the main crystal phases of the synthetic material from 1340°C to 1460°C are cordierite and mullite, and the formation of cordierite and mullite r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com